Quick-drying type epoxy primer and preparation method thereof

An epoxy primer, fast-drying technology, used in epoxy resin coatings, coatings, anti-corrosion coatings, etc., can solve the problems of unfavorable fast-paced consumer demand, long construction operation period, slow drying speed, etc., and achieve excellent results. The film is quick-drying, has a long construction time, and highlights the effect of moisture resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

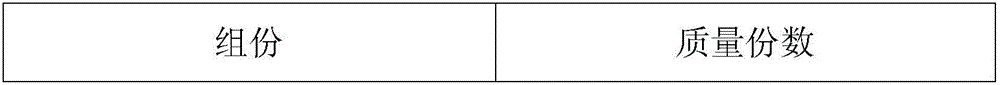

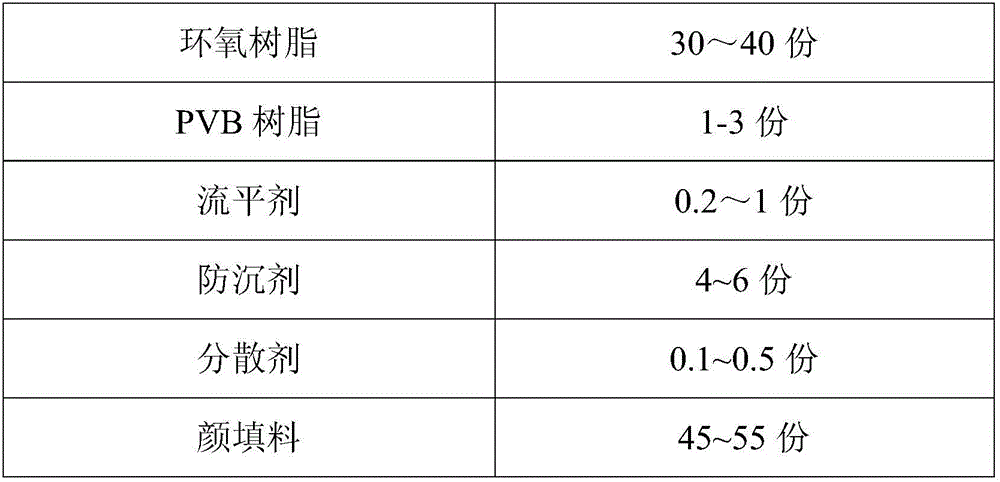

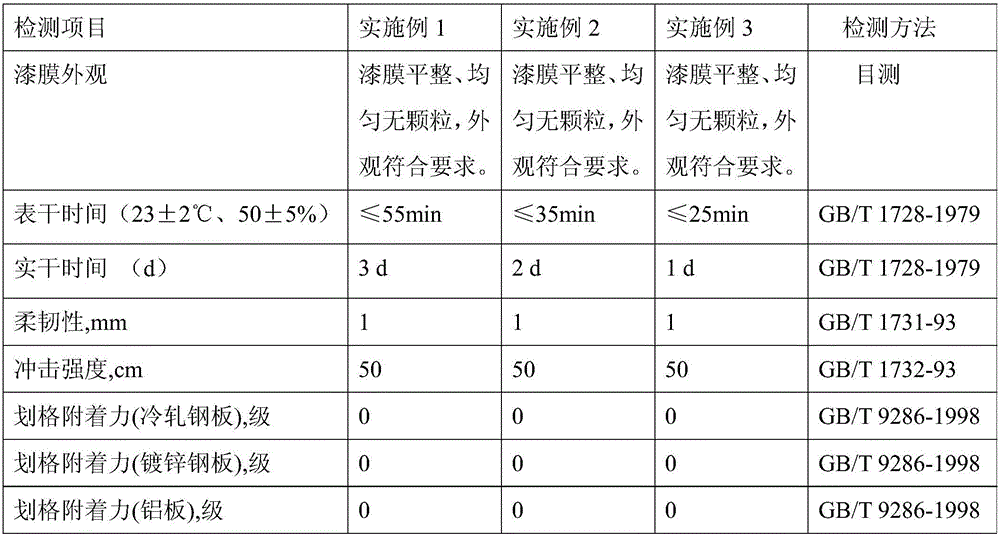

[0036] The weight components of the epoxy primer of the present embodiment are as follows: the coating part includes 35 parts of epoxy resin, 1 part of PVB resin, 0.5 part of leveling agent, 4 parts of anti-settling agent, 0.3 part of dispersant, 50 parts of pigment and filler; The agent part includes 20 parts of curing agent, 20 parts of organic solvent, and 1 part of drier.

[0037] Its preparation method is:

[0038] (1) Add the alcohol solvent into a clean container, add 1 part of PVB resin while stirring, mix and stir for 15-20 minutes until completely dissolved, and make a semi-finished product for later use;

[0039] (2) add 35 parts of epoxy resins in container, stir at low speed;

[0040] (3) Add 0.5 parts of leveling agent while stirring; 4 parts of anti-sedimentation agent; 0.3 parts of dispersant; stir evenly under low shear force;

[0041] (4) Add 50 parts of pigments and fillers while stirring, and slowly add them into the container while stirring under low she...

Embodiment 2

[0046] The weight components of the epoxy primer of the present embodiment are as follows: the coating part includes 35 parts of epoxy resin, 2 parts of PVB resin, 0.5 part of leveling agent, 4 parts of anti-settling agent, 0.3 part of dispersant, 50 parts of pigment and filler; The agent part includes 20 parts of curing agent, 20 parts of organic solvent and 2 parts of drier.

[0047] Its preparation method is:

[0048] (1) Add the alcohol solvent into a clean container, add 2 parts of PVB resin while stirring, mix and stir for 15-20 minutes until completely dissolved, and make a semi-finished product for later use;

[0049] (2) add 35 parts of epoxy resins in container, stir at low speed;

[0050] (3) Add 0.5 parts of leveling agent while stirring; 4 parts of anti-sedimentation agent; 0.3 parts of dispersant; stir evenly under low shear force;

[0051] (4) Add 50 parts of pigments and fillers while stirring, and slowly add them into the container while stirring under low s...

Embodiment 3

[0056] The weight components of the epoxy primer of the present embodiment are as follows: the coating part includes 35 parts of epoxy resin, 3 parts of PVB resin, 0.5 part of leveling agent, 4 parts of anti-settling agent, 0.3 part of dispersant, 50 parts of pigment and filler; The agent part includes 20 parts of curing agent, 20 parts of organic solvent and 3 parts of drier.

[0057] Its preparation method is:

[0058] (1) Add the alcohol solvent into a clean container, add 3 parts of PVB resin while stirring, mix and stir for 15-20 minutes until completely dissolved, and make a semi-finished product for later use;

[0059] (2) add 35 parts of epoxy resins in container, stir at low speed;

[0060] (3) Add 0.5 parts of leveling agent while stirring; 4 parts of anti-sedimentation agent; 0.3 parts of dispersant; stir evenly under low shear force;

[0061] (4) Add 50 parts of pigments and fillers while stirring, and slowly add them into the container while stirring under low s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com