Electromagnetic adsorption type protective bearing device

It is a bearing protection and adsorption technology, which is applied in the direction of bearings, shafts, bearings, mechanical equipment, etc. It can solve the problems of slow response, damage to the protection bearing, and low reliability, and achieve the effect of preventing damage and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

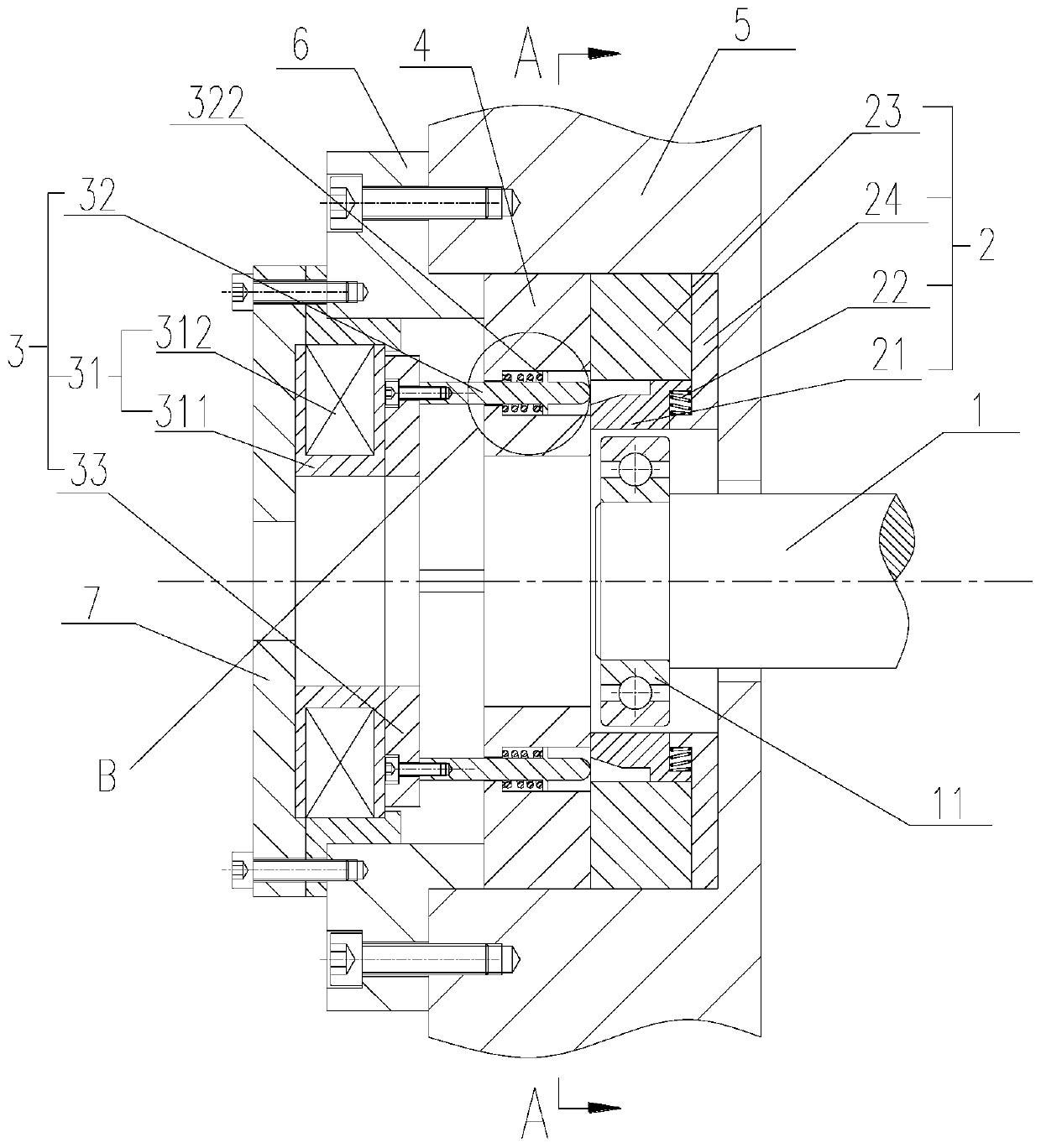

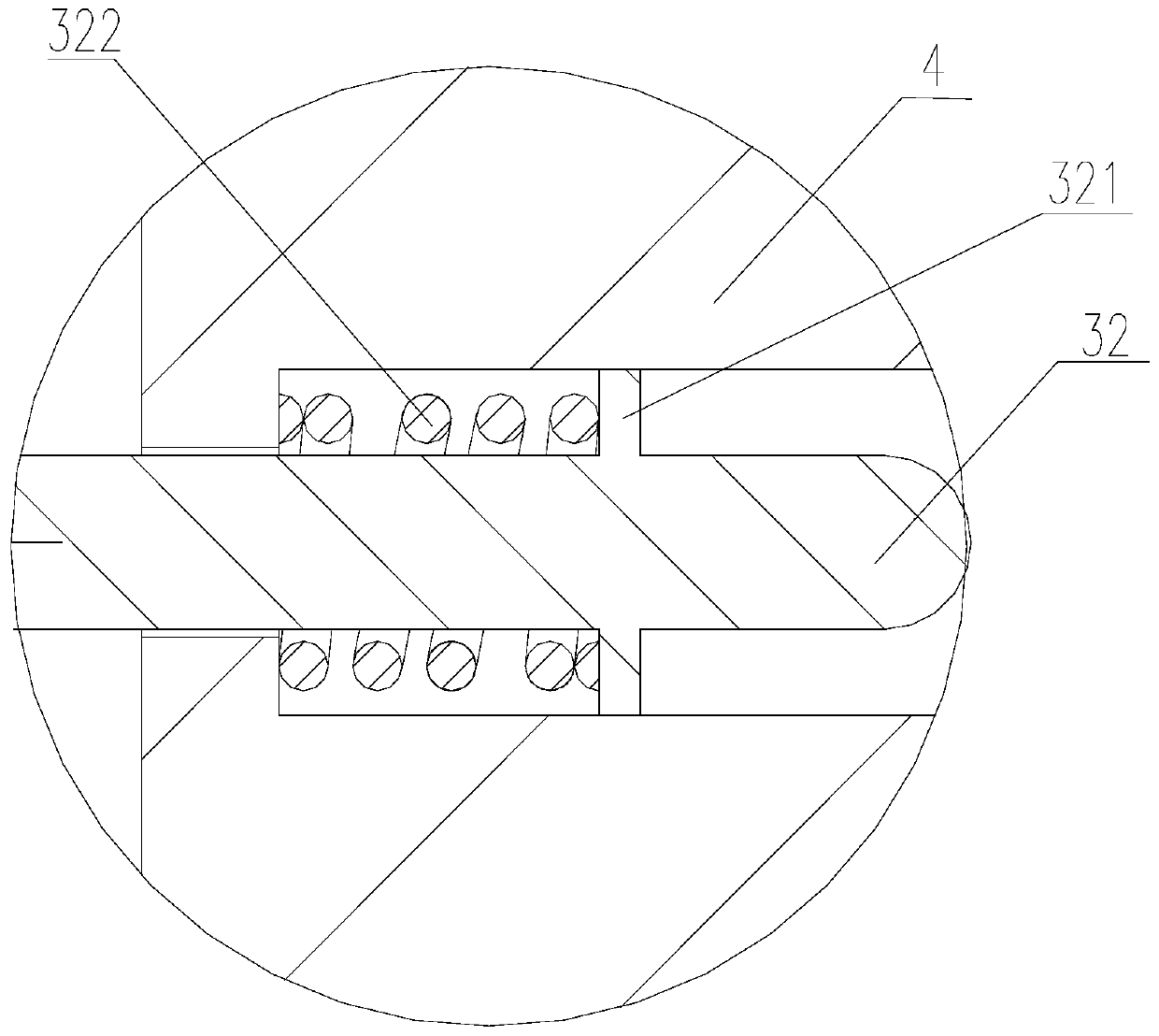

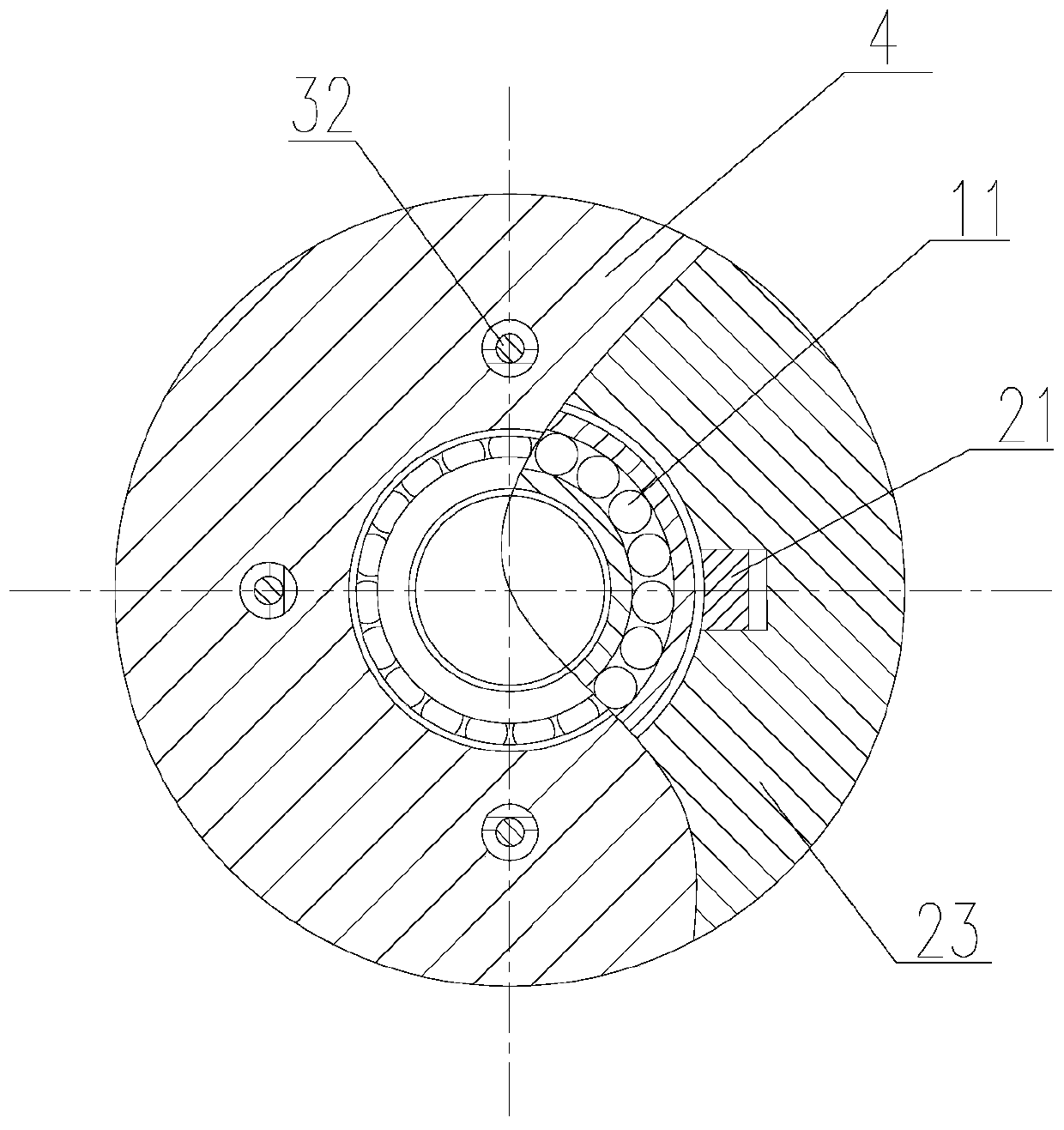

[0025] The content of the present invention will be further described below in conjunction with the accompanying drawings.

[0026] Such as Figure 1-3 As shown, this embodiment provides an electromagnetic adsorption protection bearing device, including: a rotor 1, a support assembly 2 and an electromagnetic drive assembly 3, the end of the rotor 1 is provided with a bearing 11; the support assembly 2 is located in the radial direction of the bearing 11 On the outside, the gap between the support assembly 2 and the outer peripheral surface of the bearing 11 is set; the electromagnetic drive assembly 3 controls whether the support assembly 2 is in contact with the bearing 11. When the magnetic levitation system is powered off or fails, the electromagnetic drive assembly 3 can control the support assembly 2 and the bearing. 11 contacts, the gap between the two disappears, and the support assembly 2 provides support to the bearing 11; when the magnetic levitation system works nor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com