Maglev traction device of high-temperature superconducting high-speed magnetic levitation train

A magnetic levitation train and high-temperature superconducting technology, applied in superconducting magnets/coils, electric traction, electric vehicles, etc., to simplify the structure, avoid large volume and weight, and ensure safe and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present application will be further described in detail below in conjunction with the drawings and embodiments. The following examples are used to illustrate the present application, but not to limit the scope of the present application.

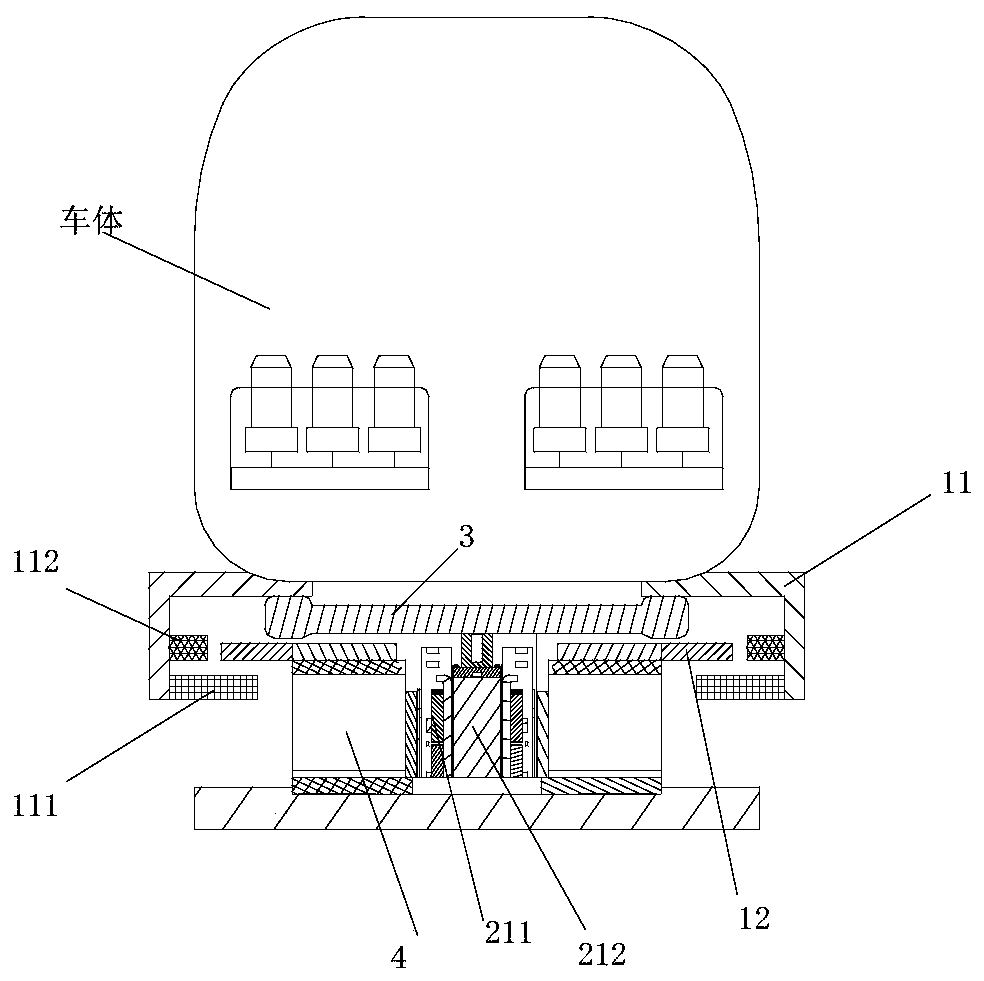

[0021] Please refer to figure 1 with figure 2 , which shows a schematic diagram of a magnetic levitation traction device for a high-temperature superconducting high-speed magnetic levitation train provided by an embodiment of the present application, as figure 1 with figure 2 As shown, the traction device includes: a high temperature superconducting magnetic levitation device 1 and a traction power device 2;

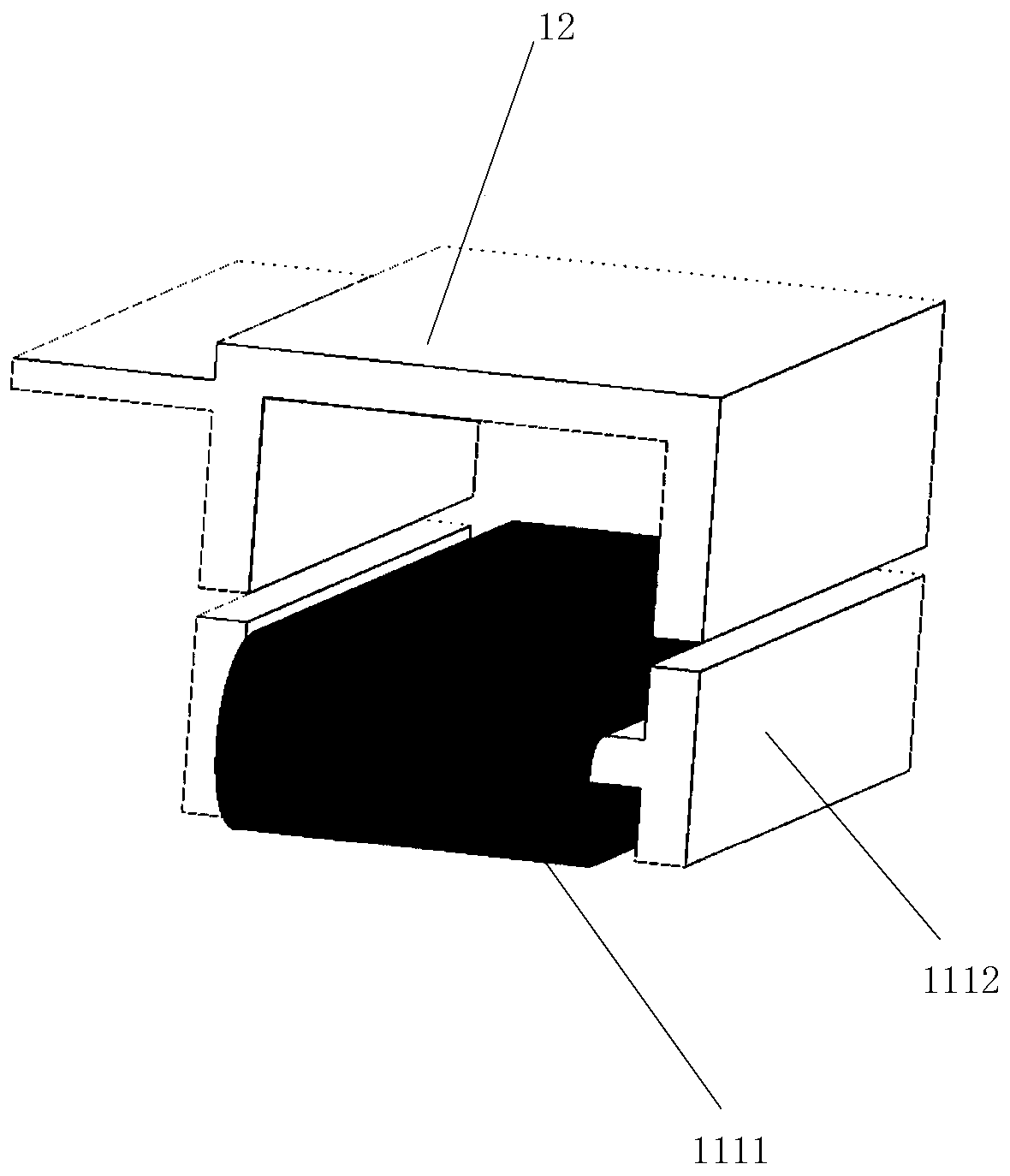

[0022] The high-temperature superconducting magnetic levitation device 1 includes car body holding rail frames 11 installed on the left and right sides of the car body bogie 3, magnetic guide rails 12 installed on the ground rails 4 on the left and right sides, a feedback control s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com