Folding type support disk

A technology for supporting discs and lugs, which is applied in the direction of vehicle cleaning equipment, etc., can solve the problems of reducing the specific pressure against the ground, large skids, and inconvenient manual handling, etc., to increase friction, increase effective working area, and save energy. The effect of manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

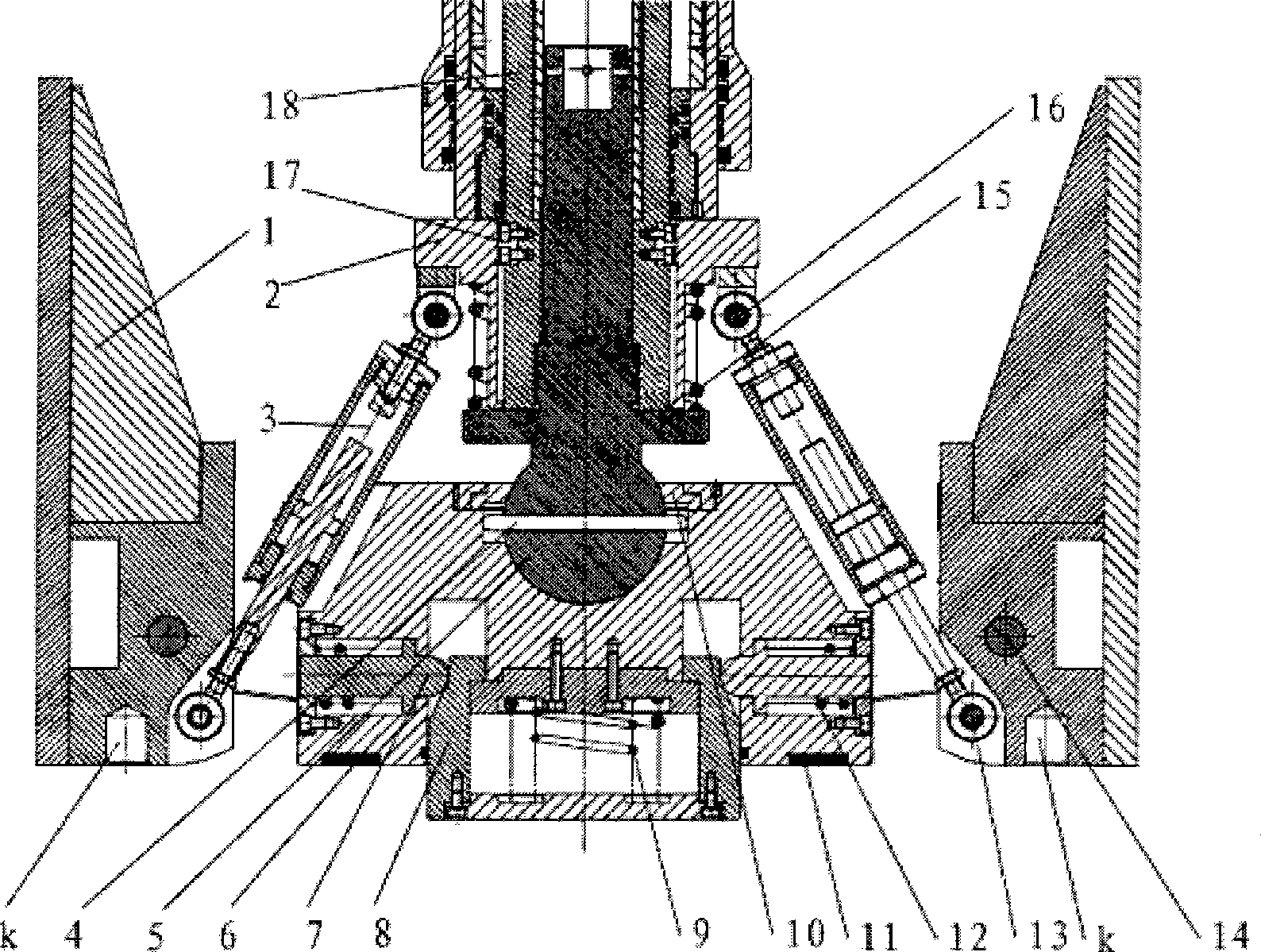

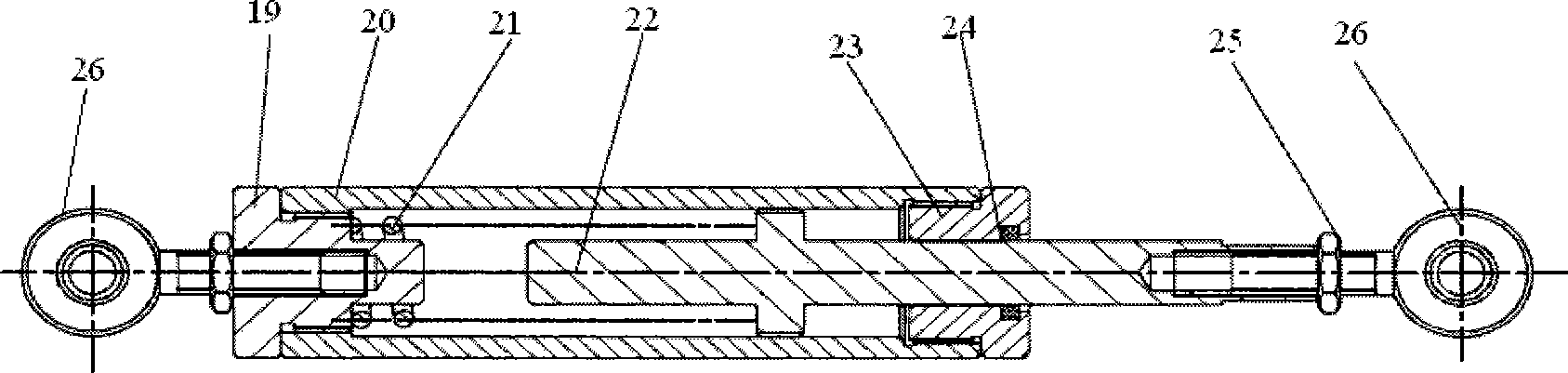

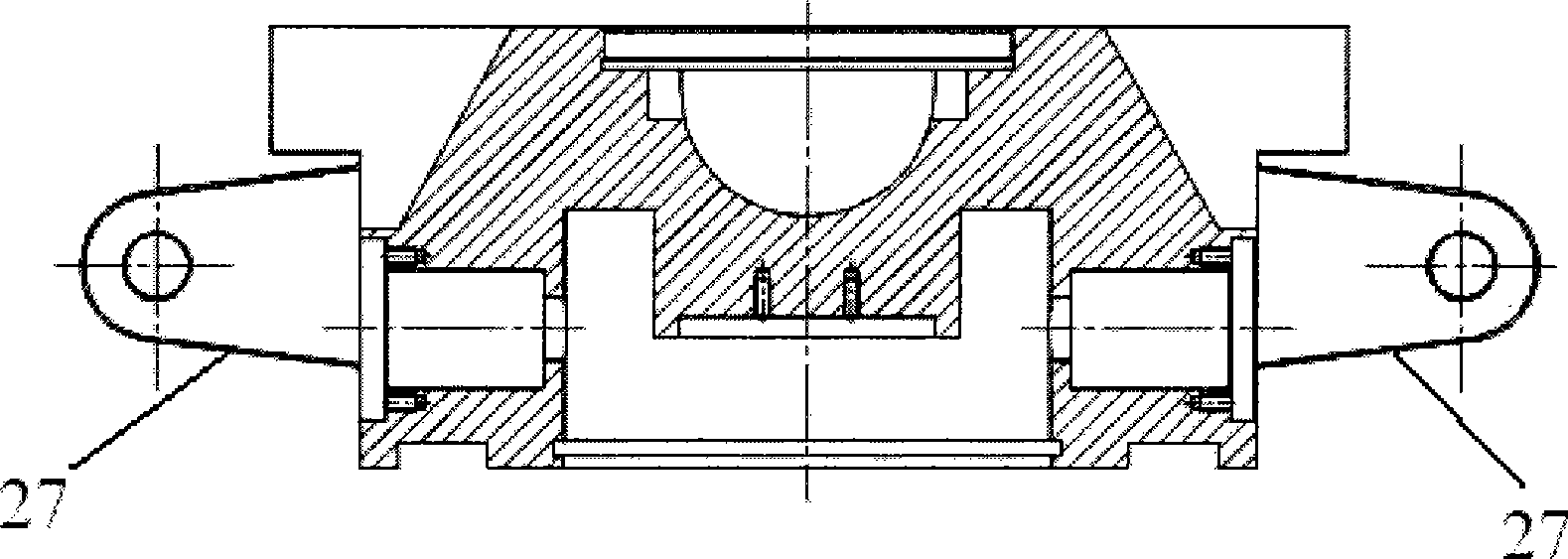

[0017] like figure 1 As shown, a collapsible support plate includes a piston 18 coupled to and driven by the vehicle. One end of the piston 18 connected to the vehicle is provided with a fixing device. The fixing device can be fixed in many ways according to different vehicles. The outer wall of the other end of the piston 18 is provided with a longitudinal pull rod sliding seat groove. The annular pull rod sliding seat 2 is provided with a key 17 , and the pull rod sliding seat 2 is fixed on the outer wall of the piston 18 through the key 17 . The fixed pull rod sliding seat 2 can only slide up and down along the pull rod sliding seat groove. A return spring 15 is provided below the pull rod sliding seat 2 on the outer wall of the piston 18 , and the pull rod sliding seat 2 is connected to the pull rod 3 through the upper shaft 16 . The upper shaft 16 is used for connecting with the joint bearing rod 26 on the tie rod 3 , and the joint bearing rod 26 can rotate in the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com