Heat pump unit and gas-liquid two-phase uniform distribution method

A heat pump unit, distributed technology, applied in the direction of refrigerators, compressors, refrigeration components, etc., can solve the problem of the area not being fully utilized, and achieve the effect of avoiding not being fully utilized, increasing the effective working area, and avoiding energy waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

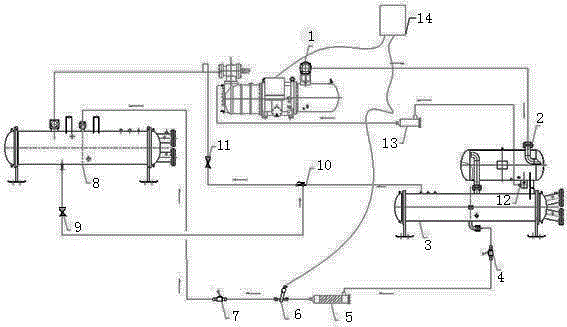

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

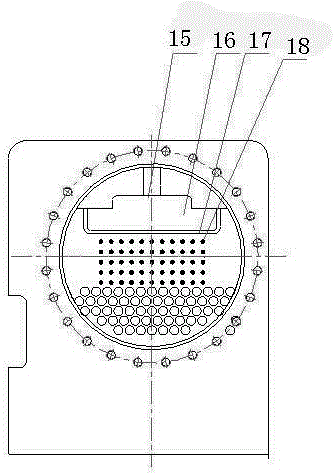

[0024] Such as figure 1 , figure 2 As shown, a heat pump unit includes a compressor 1, an oil separator 2, a condenser 3, a first ball valve 4, a dry filter 5, an electronic expansion valve 6, a second ball valve 7, and a parallel two-phase flow distribution evaporator 8. Oil return solenoid valve 9, ejector pump 10, compressor input ball valve 11, oil return angular ball valve 12, oil return filter 13. The compressor 1 communicates with the oil separator 2, the oil separator 2 communicates with the ball valve 4, the ball valve 4 communicates with the dry filter 5, and the dry filter 5 communicates with the electronic expansion valve 6 , the electronic expansion valve 6 communicates with the ball valve 7, the ball valve 7 communicates with the parallel two-phase flow distribution evaporator 8, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com