Double-sided flexible sensor and preparation method and application thereof

A flexible sensor and flexible substrate technology, applied in the field of medical devices, can solve the problems of long electrode sensing part, sensitivity difference between batches, and low scale, so as to facilitate long-term implantation, improve sensor life, and effectively The effect of a large working area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1 The double-sided flexible sensor provided by the present invention

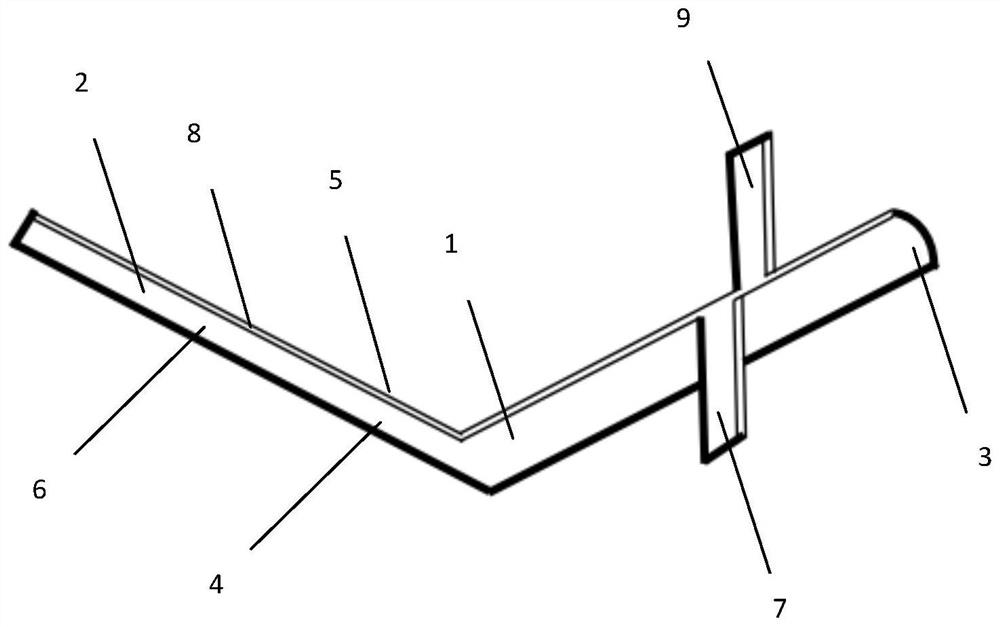

[0051] The structure of the double-sided flexible sensor provided by this embodiment is as follows: figure 1 As shown, it includes a flexible substrate 1 , the flexible substrate 1 is folded and divided into a front end 2 and a rear end 3 , and the flexible substrate 1 is a planar structure, including a first surface 4 and a second surface 5 . The first surface 4 of the flexible substrate 1 includes a first electrode 6 and a first connection location 7, and the second surface 5 includes a second electrode 8 and a second connection location 9; the detection locations of the first electrode 6 and the second electrode 8 are both Located at the front end 2; both the first connection position 7 and the second connection position 9 are located at the rear end 3, and are folded to both sides respectively.

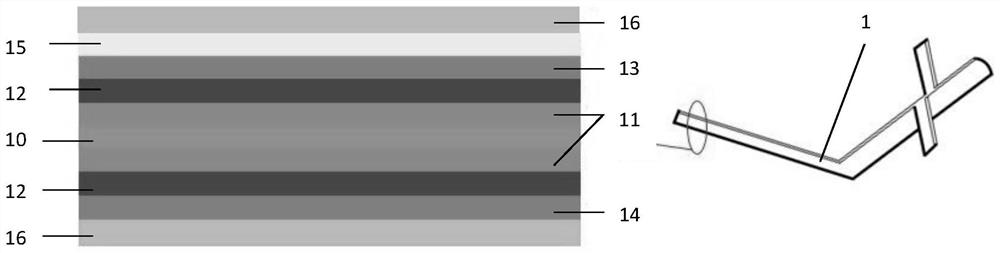

[0052] Such as figure 2 As shown, the flexible sensor provided in this embodiment has a...

Embodiment 2

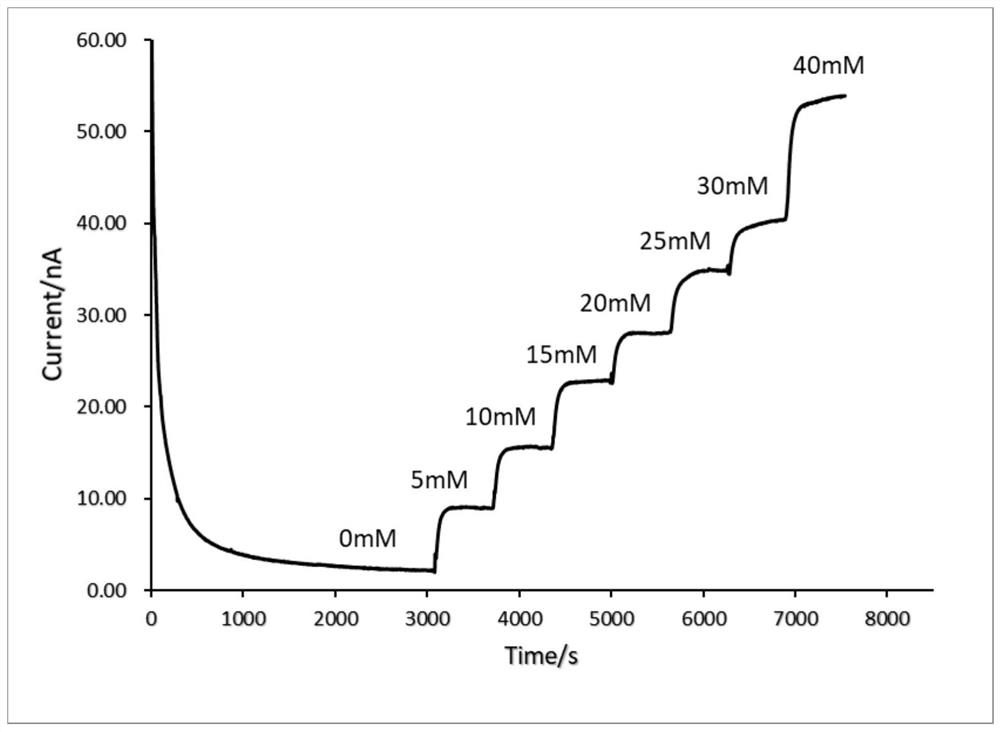

[0069] Example 2 Preparation of double-sided flexible glucose sensor

[0070] This embodiment provides a double-sided flexible glucose sensor, the preparation method of which is as follows:

[0071] (1) On both sides of the polyimide substrate (100 μm), prepare an insulating enhancement layer ParyleneC (20 μm) coating by magnetron sputtering method to form a flexible substrate;

[0072] (2) Clean the flexible substrate with absolute ethanol and deionized water, the size of which is 15*15cm;

[0073] (3) Prepare the conductive layer gold layer and the electrocatalytic layer platinum layer on the first surface by magnetron sputtering method, the thicknesses are 1 μm and 20nm respectively, after protecting the back-end connection position, pass magnetron sputtering on the back end Method for preparing insulating layer Parylene C coating;

[0074] (4) Prepare conductive layer gold layer and silver layer on its second surface, the thickness is respectively 1 μ m and 20 μ m, after...

Embodiment 3

[0081] Example 3 Preparation of another double-sided flexible glucose sensor

[0082] The preparation method of the double-sided flexible glucose sensor provided in this embodiment is as follows:

[0083] (1) On both sides of the polyethylene terephthalate substrate (100 μm), prepare the insulating enhancement layer Parylene C coating (20 μm) by magnetron sputtering method to form a flexible substrate;

[0084] (2) Clean the flexible substrate with absolute ethanol and deionized water, the size of which is 15*15cm;

[0085] (3) Prepare conductive layer carbon layer by magnetron sputtering method on the first surface, the thickness is respectively 5 μm, after protecting the back end connection position, prepare insulating layer Parylene C coating by magnetron sputtering method at the back end;

[0086] (4) Prepare conductive layer gold layer and silver layer on the second surface, the thickness is respectively 1 μ m and 20 μ m, after protecting the back end connection position...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com