Flexible clamping tool for rotary positioning of bent pipe

A flexible clamping and clamping tooling technology, applied in auxiliary devices, manufacturing tools, metal processing equipment, etc., can solve the problems of inability to solve the problems of rotation and displacement of multiple elbows, weak adaptability, and high tooling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

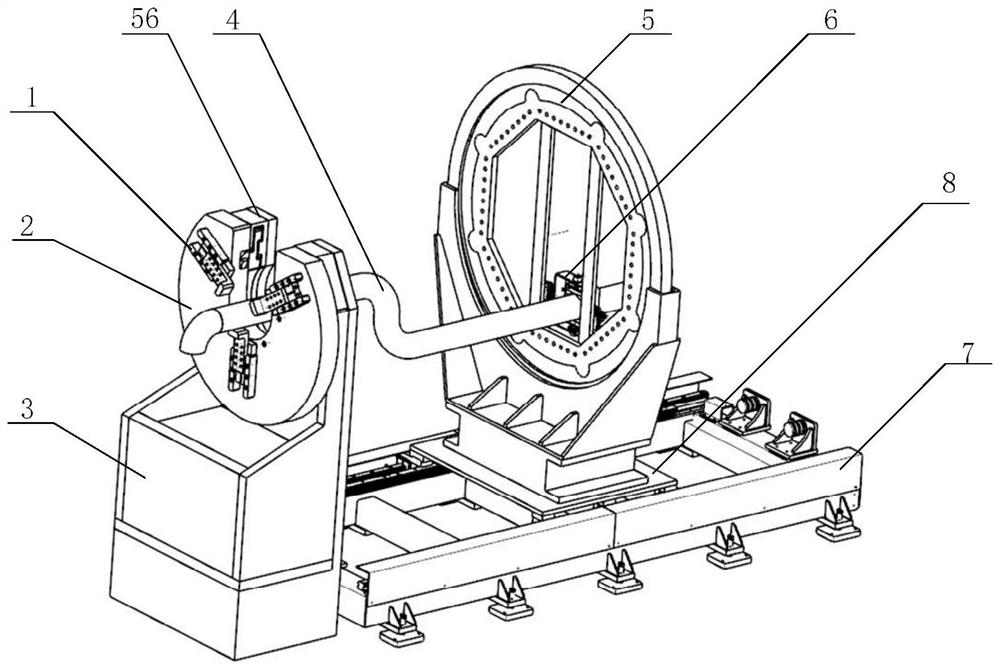

[0013] Such as figure 1 As shown, a flexible clamping tool for the rotation and displacement of an elbow, including an open positioner 3, an R-type positioner 5, a clamping tool 6 and a track 7;

[0014] The open positioner 3 is used to clamp the area near the elbow 4 to be welded and rotated; the R-type positioner 5 is used to clamp the other end of the elbow 4 and rotated; the The clamping tool 6 is flexibly adjusted and clamped on the R-type positioner 5; the R-type positioner 5 is installed above the track 7 through a slide plate 8 and slides freely, and can adapt to bends 4 of different lengths.

[0015] Further, the open positioner 3 includes an electric chuck 1, a rotating mechanism 2 and a driving mechanism 56, the electric chuck 1 is used to clamp the bent pipe 4, and the driving mechanism 56 drives the electric chuck 1 to rotate to realize bending Rotary movement of tube 4 clamping position.

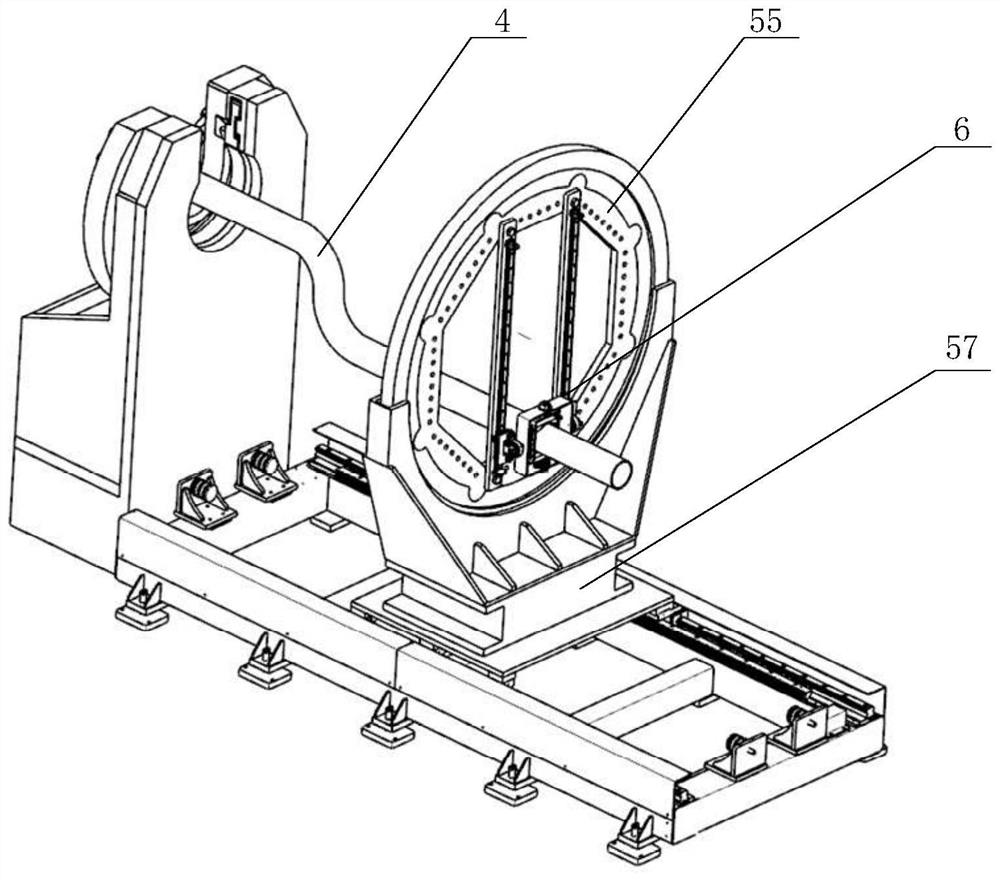

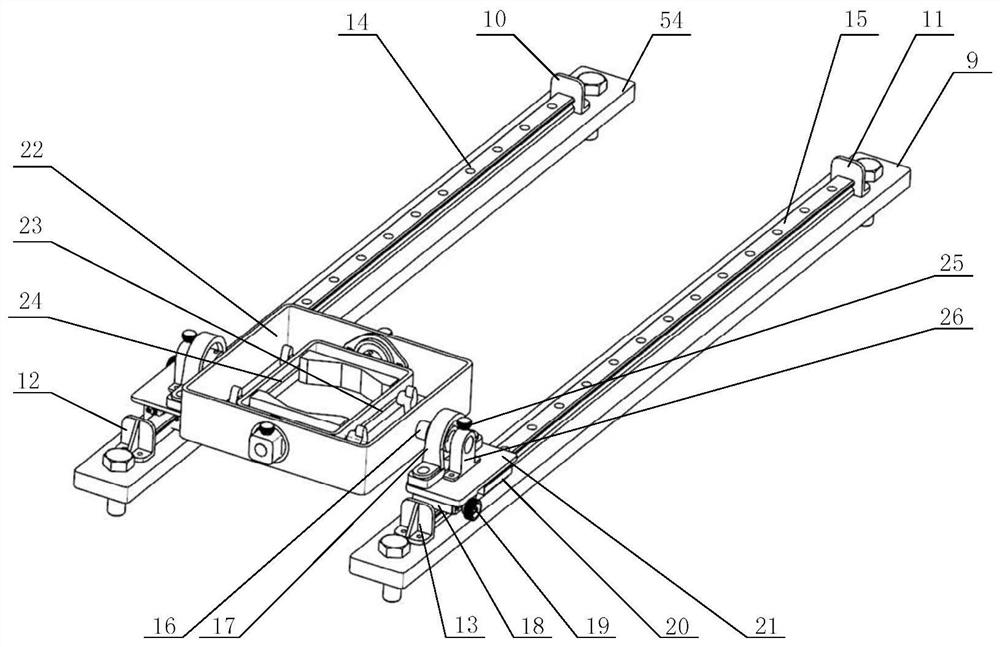

[0016] Further, such as figure 2 As shown, the R-type positioner 5 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com