Camber angle changing mechanism

A camber angle, variable technology, applied in the direction of steering mechanism, elastic suspension, cantilever installed on the pivot, etc., can solve the problems of fuel consumption rate deterioration, space requirement, increased weight, etc., to achieve fewer parts and light weight The effect of low cost and strong resistance to external forces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

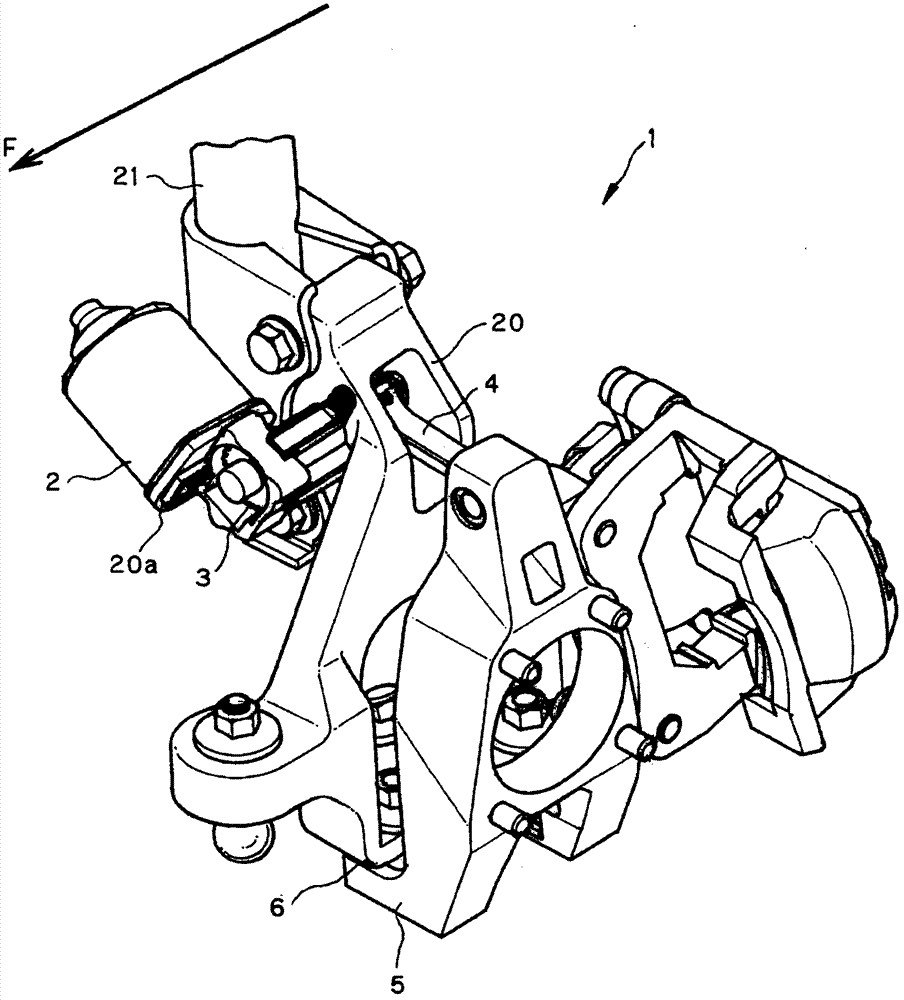

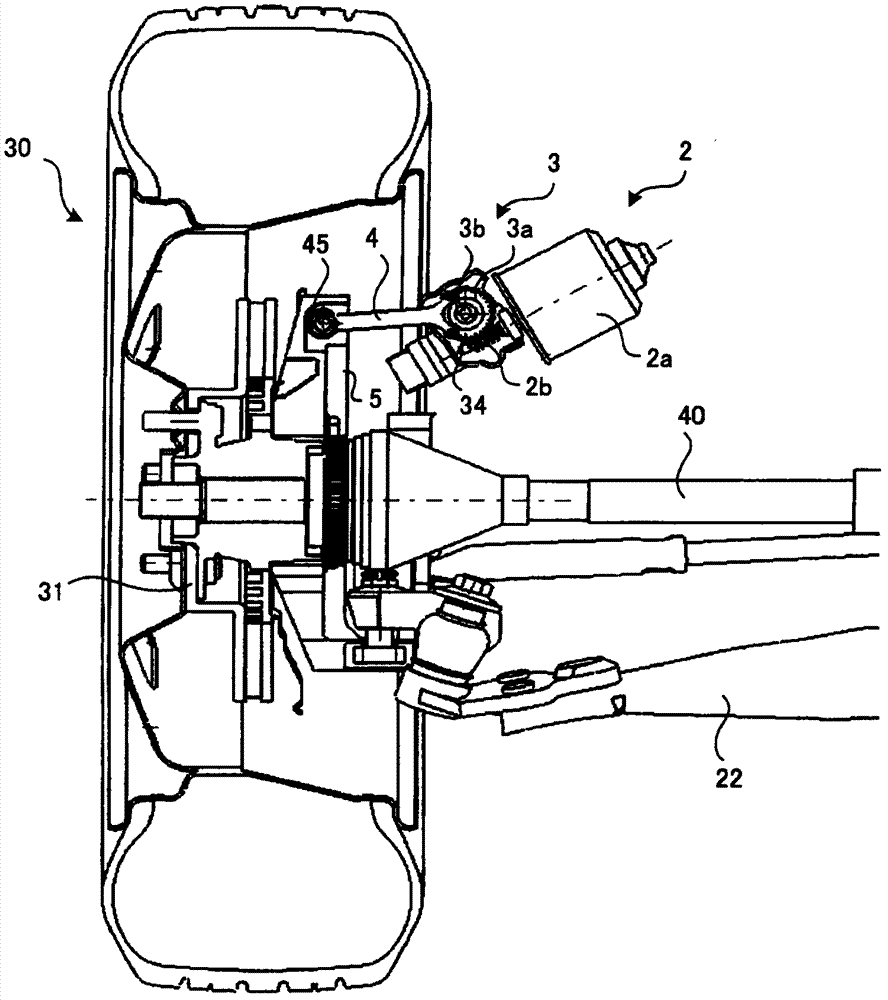

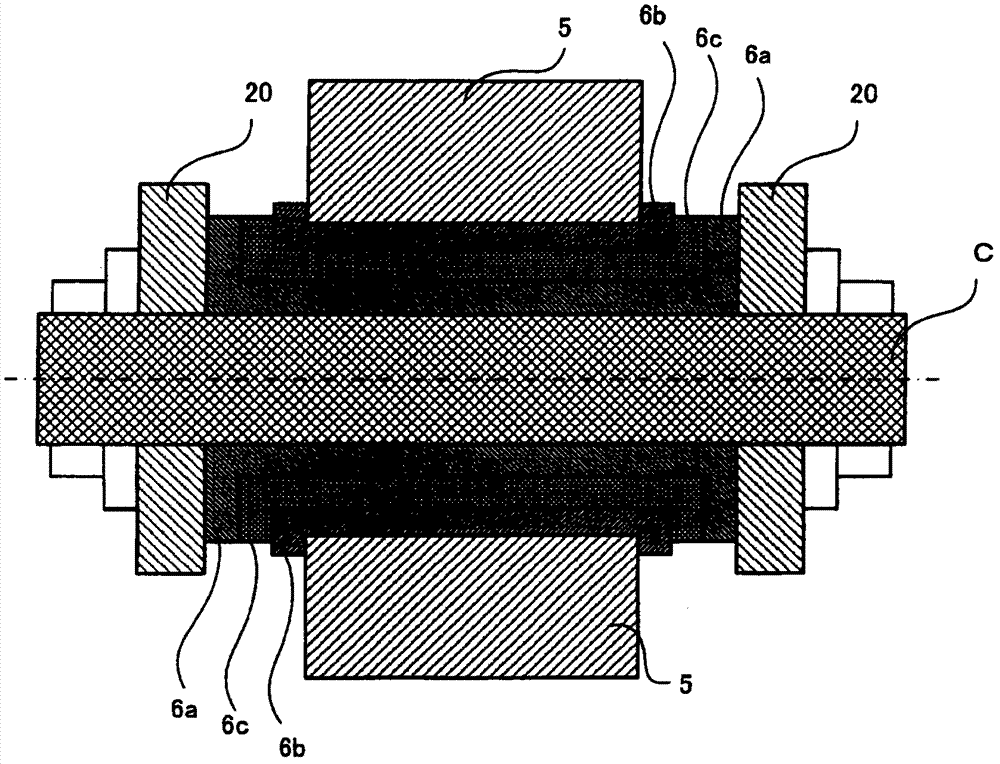

[0054] figure 1 It is a perspective view showing the camber angle variable mechanism 1 of the first embodiment seen from the upper front. figure 2 It is a figure which shows the camber angle variable mechanism 1 of 1st Embodiment seen from the rear. Among them, in figure 2 In FIG. 1 , the support rod and the steering knuckle are omitted for easy observation of the camber angle variable mechanism 1 .

[0055] In addition, front and rear here correspond to the front and rear directions of the vehicle, and arrow F in the figure indicates the front. In addition, the vehicle width direction refers to a direction perpendicular to the front-rear direction of the vehicle (the same applies hereinafter).

[0056] exist figure 1 and figure 2 Among them, 1 represents the camber angle variable mechanism, 2 represents the motor, 3 represents the worm wheel as the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com