Integrated machine for automatically aligning, shearing and measuring distance of cotton covered wire

A technology of wiring and all-in-one machines, applied in the field of all-in-one machines, can solve problems such as time-consuming, labor-intensive, material damage, and waste of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

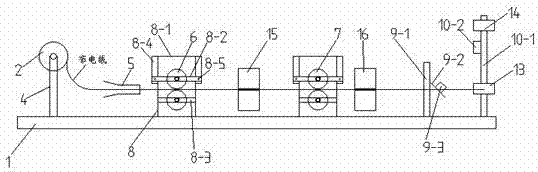

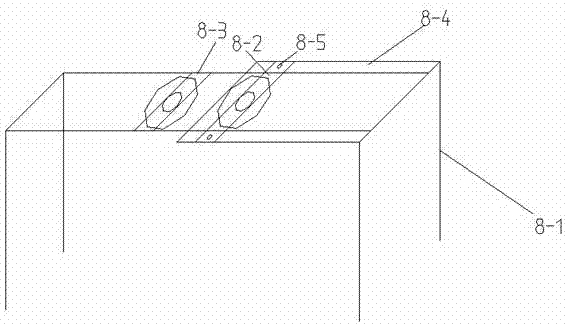

[0025] Example 1. refer to Figure 1-2 . The all-in-one machine for automatic straightening, distance measuring, and cutting of wires and wires includes a base 1 on which a tension reel 2 for placing wires is arranged. The tension reel 2 is driven by a wiring motor 3. The tension reel 2 The output end of the straightening mechanism is provided with a straightening mechanism, the output end of the straightening mechanism is provided with a distance measuring mechanism, and the output end of the distance measuring mechanism is provided with a shearing mechanism to control the tension coil 2, the straightening mechanism, the distance measuring mechanism, and the shearing mechanism The control device for opening and closing, the distance measuring mechanism is connected with the signal input end of the computer, and the tension line reel 2, the straightening mechanism and the cutting mechanism are connected with the signal output end of the computer.

Embodiment 2

[0026] Example 2. refer to Figure 1-2 . The all-in-one machine for automatic straightening, distance measuring, and cutting of electric wires includes a machine base 1 on which a support 4 is installed. Driven by motor 3, the output end of tension wire reel 2 is provided with straightening mechanism, and between described tension wire reel 2 and straightening mechanism, be provided with bell-mouth wire groove 5, the output end of straightening mechanism is provided with distance measuring mechanism, measuring The output end of the distance mechanism is provided with a shearing mechanism, which controls the tension wire reel 2, the straightening mechanism, the distance measuring mechanism, the control device for opening and closing the shearing mechanism, and the distance measuring mechanism is connected with the signal input end of the computer. The tension wire reel 2, the straightening mechanism and the shearing mechanism are connected with the signal output end of the co...

Embodiment 3

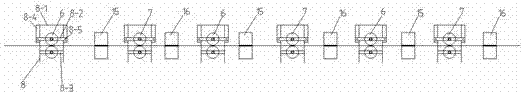

[0034] Example 3. This embodiment is basically the same as Embodiment 2, except that the tension roller group 6, the vertical tension roller group 15, the moving traction roller group 7, and the vertically moving traction roller group 16 are respectively provided with 4 groups.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com