Follow-up turnover equipment for hoisting equipment and follow-up turnover hoisting method

A technology of hoisting equipment and turning equipment, which is applied to cargo handling equipment, passenger handling equipment, transportation and packaging, etc., can solve the problems of high requirements on site ground quality, slow running of crawler, low work efficiency, etc., and achieve the lifting and turning process. The effect of stability, good versatility, and safe flipping and hoisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

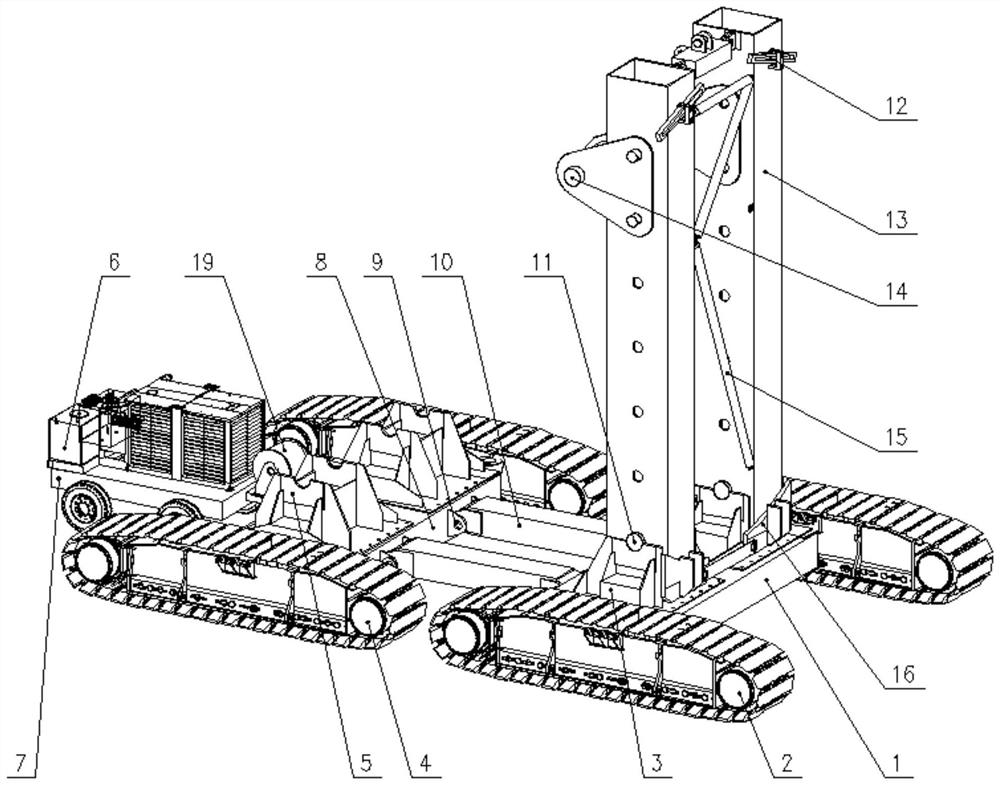

[0048] like figure 1 As shown, the following turning equipment for hoisting equipment provided by the embodiment of the present invention includes: a walking chassis and a front turning support base 3 , a rear turning support base 5 , and a turning platform respectively arranged on the walking chassis.

[0049]Described walking chassis comprises: front car body 1, rear car body 8 and two connecting beams 10 that are connected between front car body 1, rear car body 8; Two connecting beams 10 can make front car body 1 and rear car Body 8 is firmly connected. The front car body 1 and the rear car body 8 are respectively provided with crawler belts, wheels or slide rail mechanisms on both sides, so that the walking chassis can be a crawler chassis, a wheeled chassis, and a slide rail mechanism according to actual needs. Various working environments. The walking chassis of this embodiment can adjust the working position according to different working environments, which is more ...

Embodiment 2

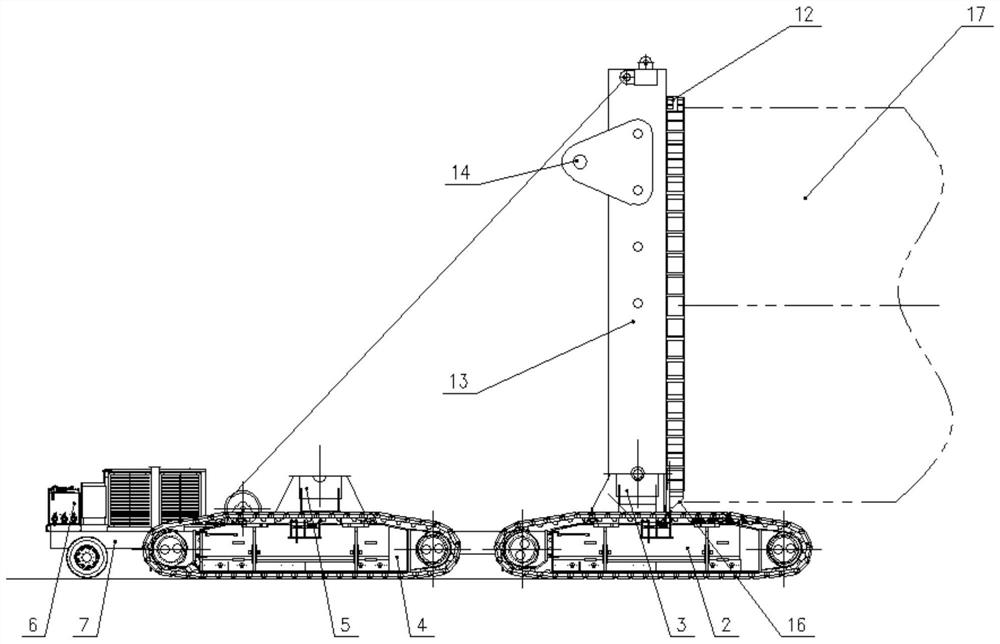

[0064] This embodiment provides a follow-up flip hoisting method, using the follow-up flip device for hoisting equipment provided by any embodiment of the present invention, such as Figure 5 to Figure 7 As shown, the following flip hoisting method includes the following process:

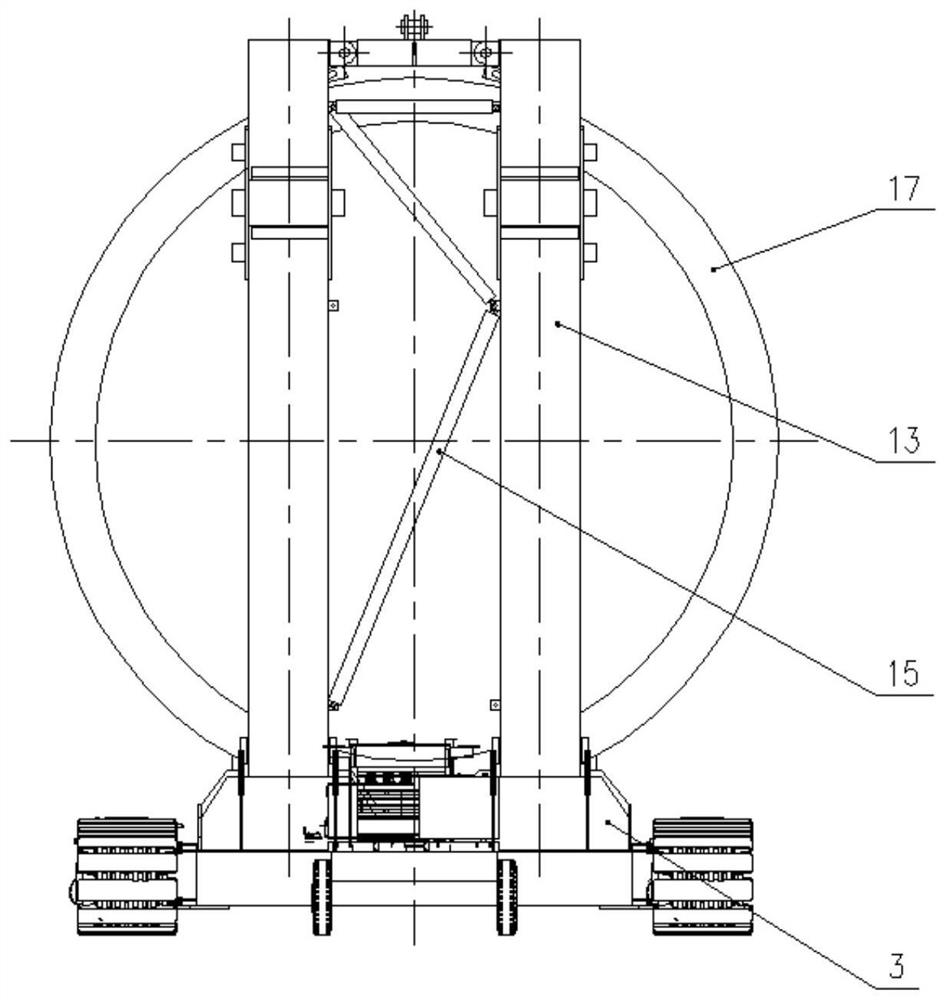

[0065] Step 1, the initial state of the hoisting device 17 is in a horizontal position, and it will follow the flipping device to travel to the tail of the hoisting device 17, and the support shaft 11 and the platform support seat 14 of the flipping platform are respectively placed on the front flipping support seat 3 and the rear flipping support seat 5, The hoist 19 releases the rope following the turning platform, and the hoisting device turns the turning platform clockwise around the front turning support base 3 to a vertical position, so that the turning platform fits the skirt seat of the hoisting device 17;

[0066] Step 2, adjust the hoisting bracket 16 so that the lower arc of the skirt of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com