Grouping and air-pairing installation method for corridor

A technology of aerial pairing and corridors, which is applied in the fields of architecture, building structure, and building material processing, etc., can solve the problem of high entry and exit fees and rental costs of large-scale hoisting equipment, frequent assembly of steel structures, and the impact of building occupancy. problems, to optimize other construction projects, reduce hoisting costs, and achieve the effect of large operating radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

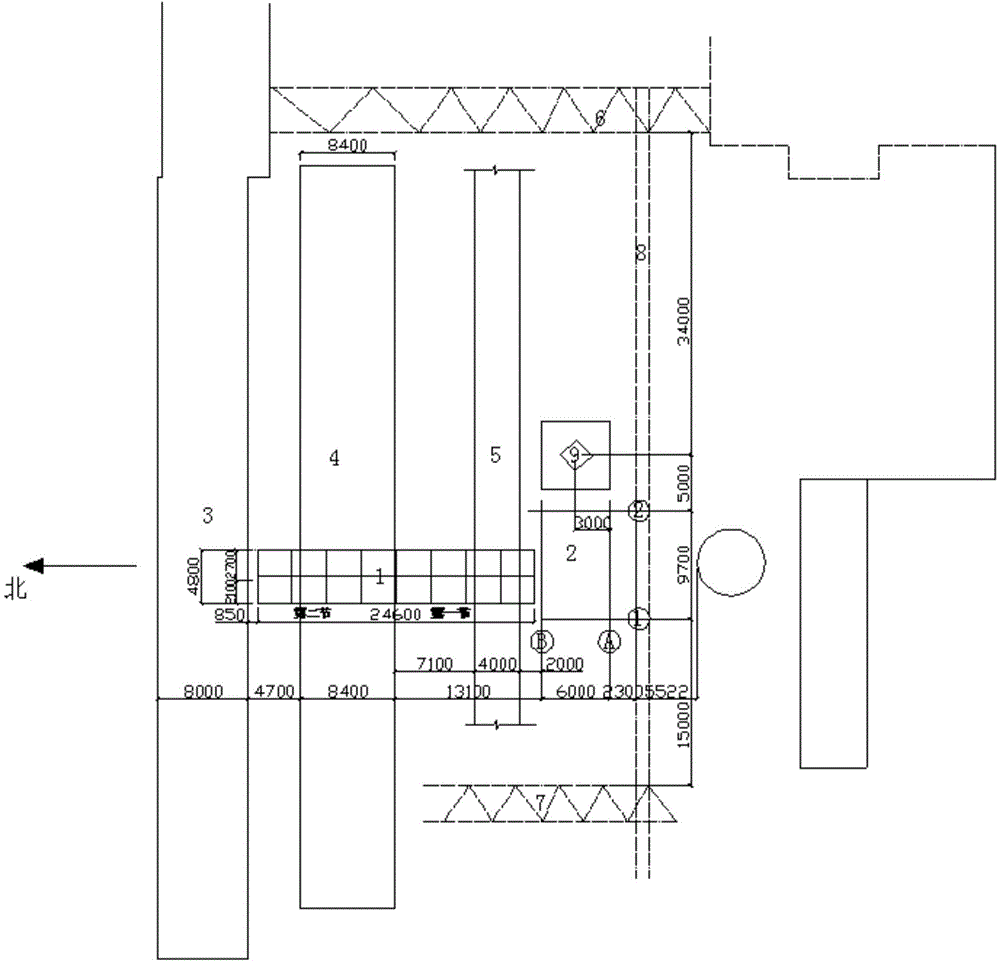

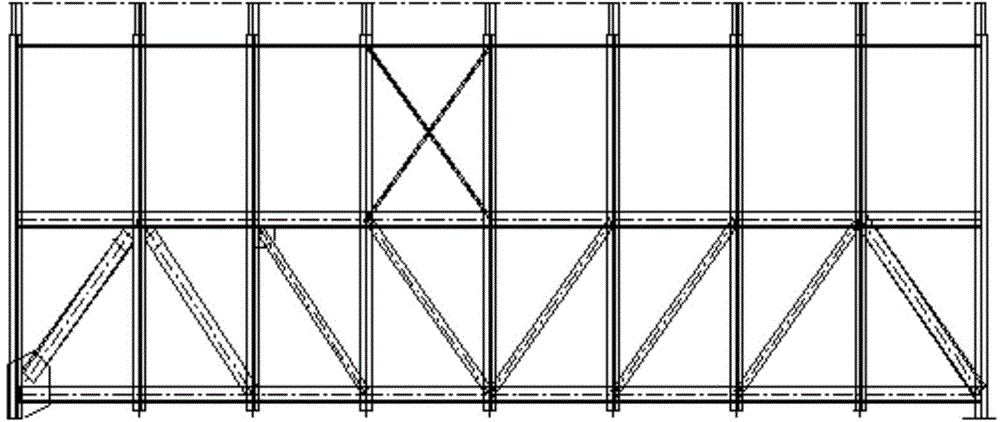

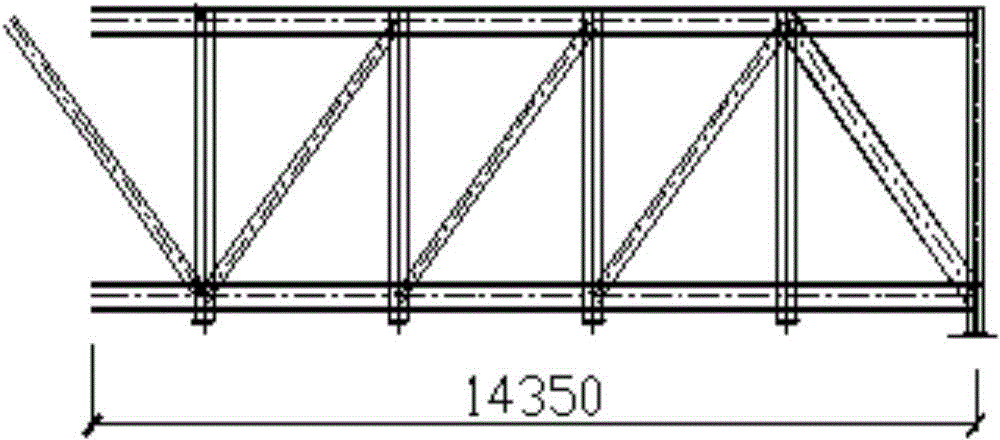

[0025] 1) Determination of the corridor grouping air grouping scheme: In order to ensure the accurate and safe installation of the corridor, on-site inspection and measurement of the installation site shall be carried out in advance. The M-2 corridor needs to cross the original old coal blending room and the chemical production pipeline corridor ( In use), in order not to affect the normal operation of the original production department, it is considered to use a 650t crawler crane to hoist the corridor as a whole. However, due to the small construction site, there are two corridors on the east side that have been put into production and cannot be dismantled, resulting in the 650t crane. Assembling, and the cost of entering and leaving the site with a 650t crane is high, so this plan cannot be implemented. According to the actual situation of the site, depending on the narrow construction site, many production operations coexist in the surrounding area. After many on-site measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com