Fully assembled segmented anti-buckling supporting member with crossed cores capable of being directly replaced

An anti-buckling bracing, cross-shaped technology, applied in earthquake resistance, building types, protective buildings/shelters, etc., to achieve the effect of reducing construction cost, simple and quick repair work, and improving efficacy and time-efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

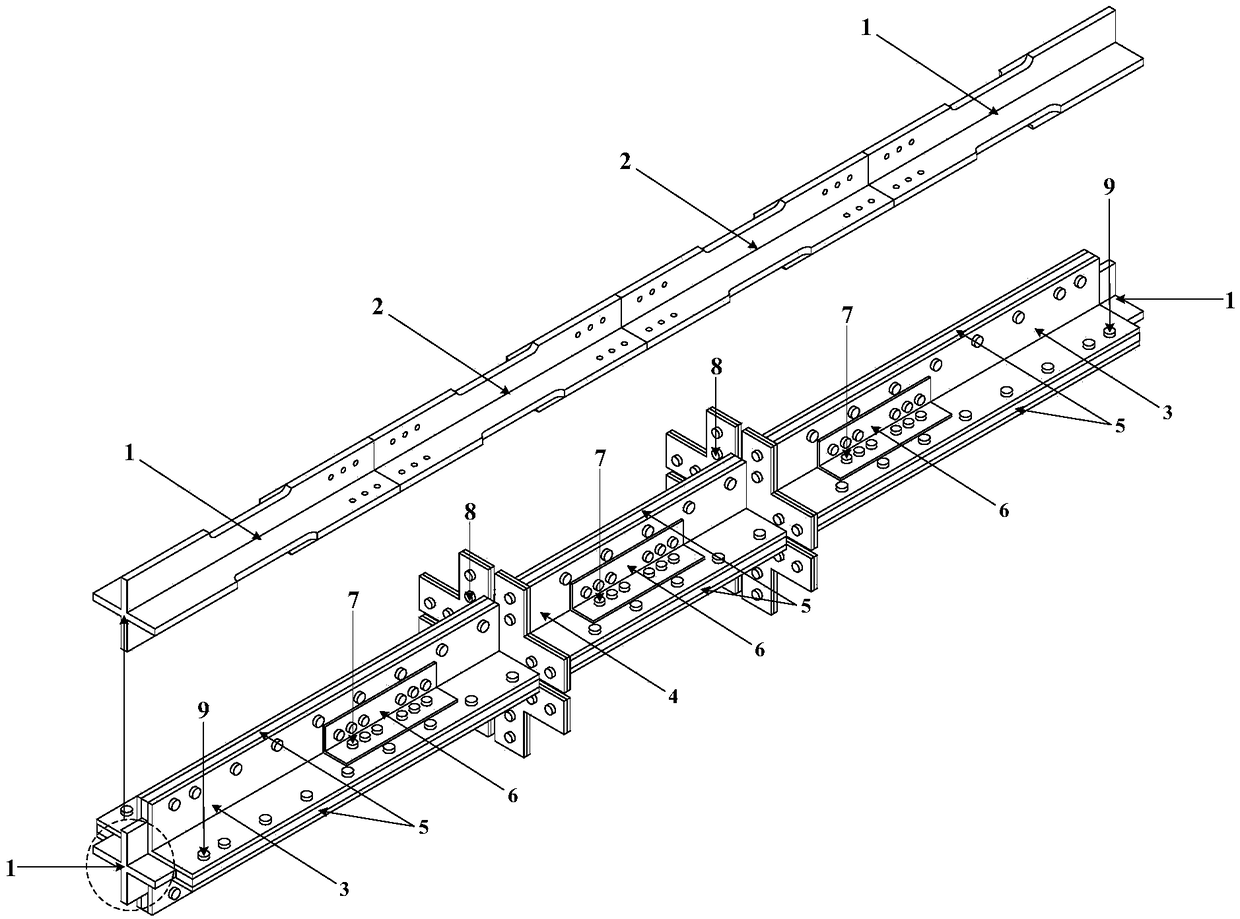

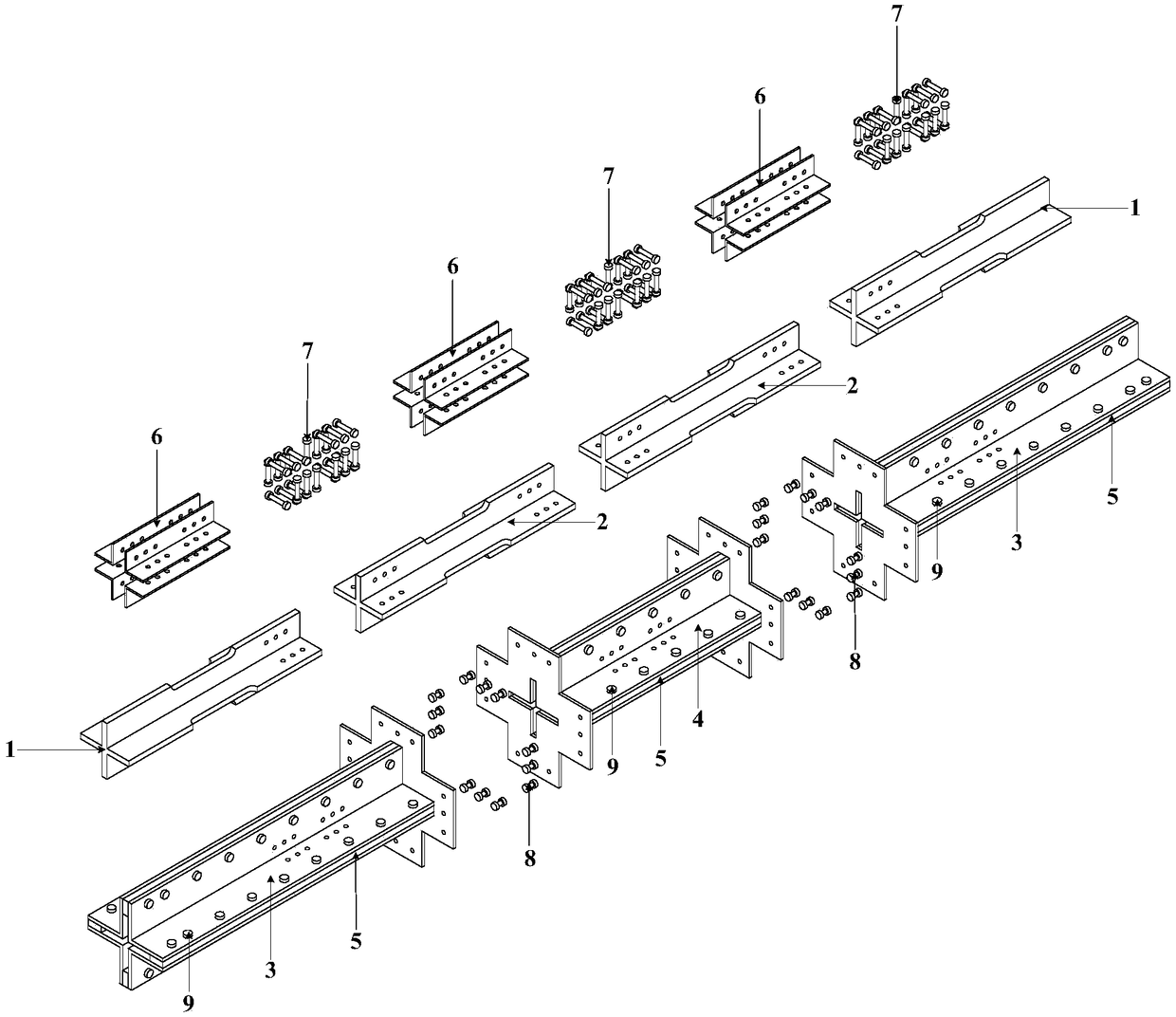

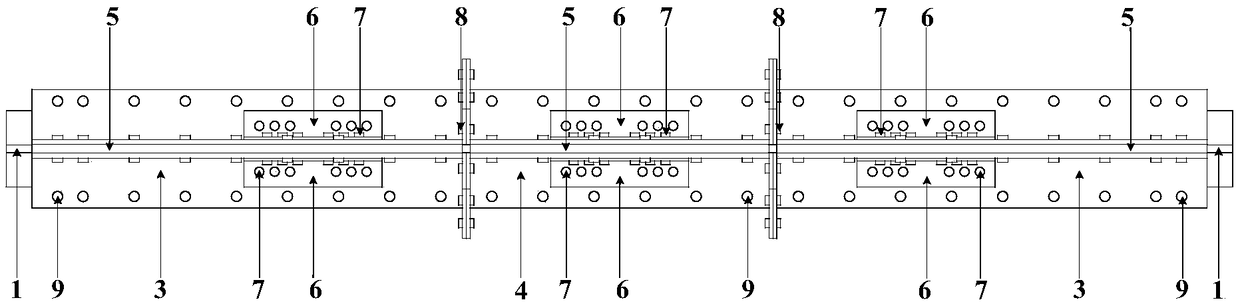

[0029] Attached below Figure 1-8 , detailing the implementation of this patent.

[0030] Such as Figure 1-8 As shown, a fully assembled segmented buckling restraint that can directly replace the cross-shaped core includes the following components:

[0031] 1——Side section cross-shaped core member;

[0032] 2——the cross-shaped inner core component in the middle section;

[0033] 3——Side angle steel member with end plate;

[0034] 4——the middle section angle steel member with end plate;

[0035] 5 - backing plate;

[0036] 6——L-shaped connector outside the inner core;

[0037] 7——The first high-strength bolt group;

[0038] 8——The second high-strength bolt group;

[0039] 9——High-strength bolt group 3;

[0040] 10——Assembled side segment peripheral restraint device unit;

[0041] 11——Assembled middle section peripheral restraint device unit;

[0042] 12——The end reinforcement area of the cross-shaped core member of the side section;

[0043] 13——the central weake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com