Diamond wire saw and preparation method thereof

A diamond wire saw and diamond particle technology are applied in the field of diamond wire saw and its preparation, which can solve the problems of large diameter and low strength of diamond wire saw, and achieve the effects of eliminating friction process, improving strength and strong controllability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

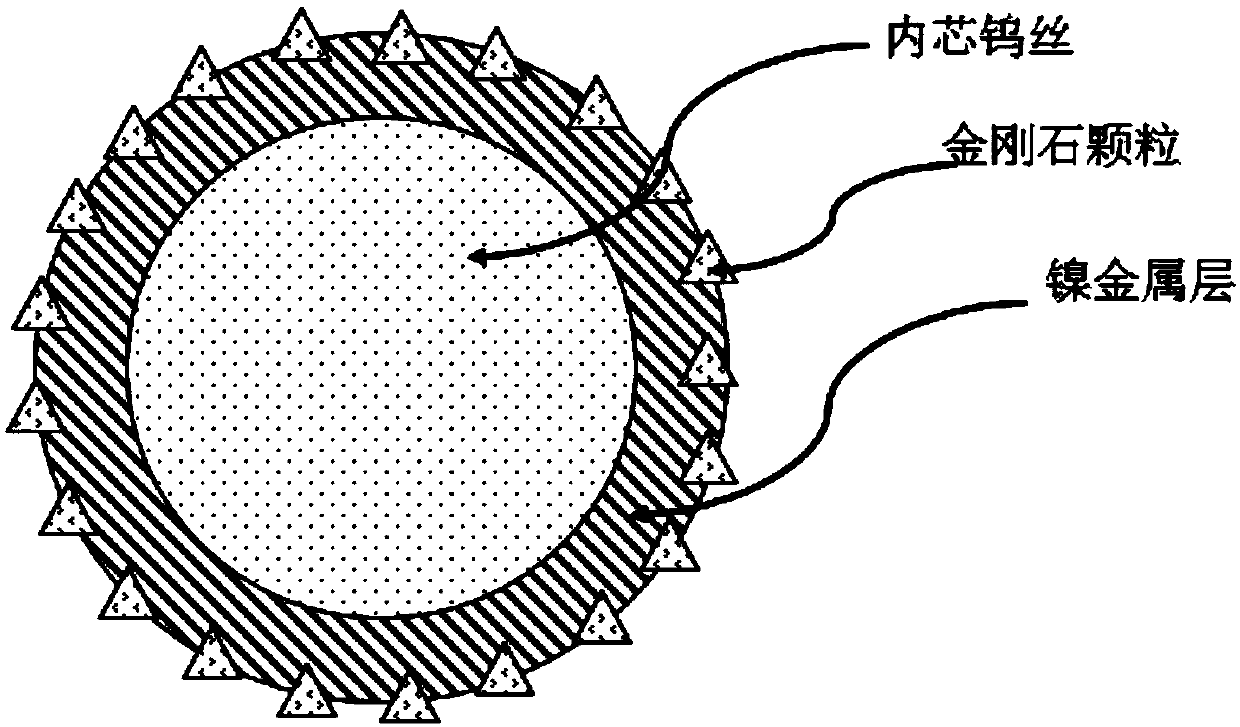

[0036] Such as figure 1 As shown, a diamond wire saw is composed of a wire saw core in the middle and a nickel metal layer on the surface. In this embodiment, the diamond wire saw core is a tungsten wire, and the content of tungsten is 99.95%; the surface is 3 μm in thickness. A nickel metal layer and diamond particles having an average particle diameter D50 of 7.5 μm.

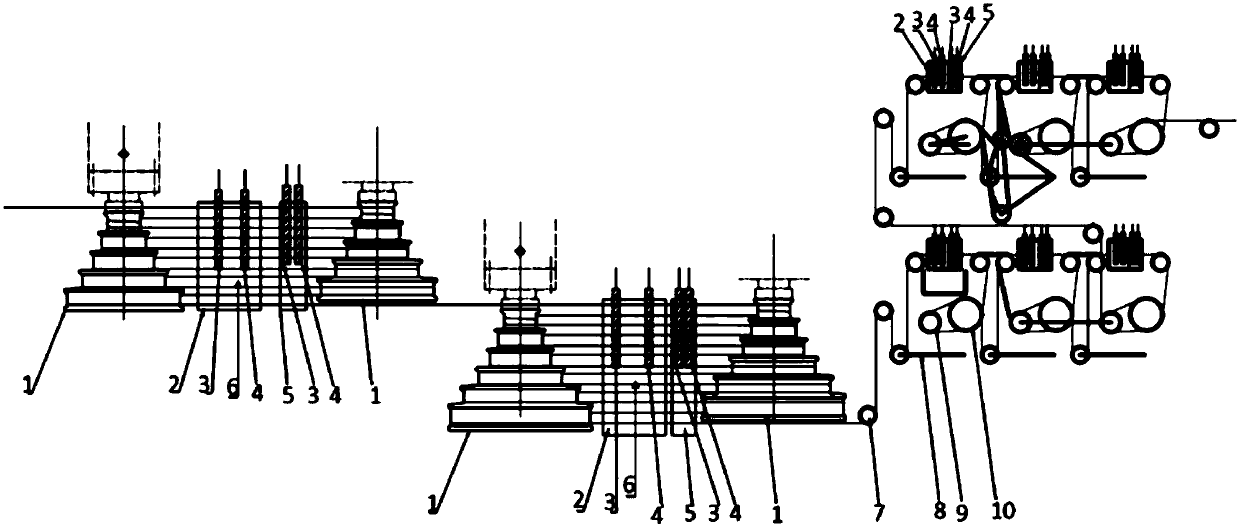

[0037] Such as figure 2 As shown, a kind of diamond wire saw prepared by the present invention is processed by 28 times of continuous drawing, which specifically includes the following steps:

[0038] (1) The tungsten wire enters the sliding drawing processing mold through the traction tower pulley 1 for 22 passes of sliding drawing processing; the temperature of the heating box 2 and the mold box 5 are controlled separately, and the heating temperature of the heating box 2 is 350 ℃, the heating temperature of the mold box 5 is 250 ℃; the lubricant 6 is graphite emulsion S-0; the hardness of the traction to...

Embodiment 2

[0043] A diamond wire saw is composed of a wire saw core in the middle and a nickel metal layer on the surface. In this embodiment, the diamond wire saw core is a tungsten wire, and the content of tungsten is 99.9%; the surface is a nickel metal layer with a thickness of 1 μm. and diamond particles with an average particle diameter D50 of 4 μm.

[0044] A diamond wire saw prepared by the present invention is processed through 28 passes of continuous drawing, specifically comprising the following steps:

[0045] (1) The tungsten wire enters the sliding drawing processing mold through the traction tower pulley 1 for 22 passes of sliding drawing processing; the temperature of the heating box 2 and the mold box 5 are controlled separately, and the heating temperature of the heating box 2 is 200 ℃, the heating temperature of the mold box 5 is 170 ℃; the lubricant 6 is graphite emulsion S-0; the hardness of the traction tower pulley 1 is HRC72; the drawing speed is 30m / min;

[0046] ...

Embodiment 3

[0050] A diamond wire saw, which is composed of a wire saw core in the middle and a copper metal layer on the surface. In this embodiment, the diamond wire saw core is a tungsten wire, and the content of tungsten is 99.9%; the surface is a copper metal layer with a thickness of 10 μm and diamond particles with an average particle diameter D50 of 10 μm.

[0051] A diamond wire saw prepared by the present invention is processed through 28 passes of continuous drawing, specifically comprising the following steps:

[0052] (1) The tungsten wire enters the sliding drawing processing mold through the traction tower pulley 1 for 22 passes of sliding drawing processing; the temperature of the heating box 2 and the mold box 5 are controlled separately, and the heating temperature of the heating box 2 is 600 °C, the heating temperature of the mold box 5 is 500 °C; the lubricant 6 is graphite milk S-0; the hardness of the traction tower pulley 1 is HRC72; the drawing speed is 200m / min; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com