Strip material roll shearing roll extruding mechanism

A technology of rolling shear and strip, applied in metal rolling, manufacturing tools, metal processing equipment, etc., can solve the problems of affecting the appearance quality, the uncoiler occupies a large space, and the tension is not easy to control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to better understand the present invention, now the specific embodiment of the present invention is described in conjunction with accompanying drawing:

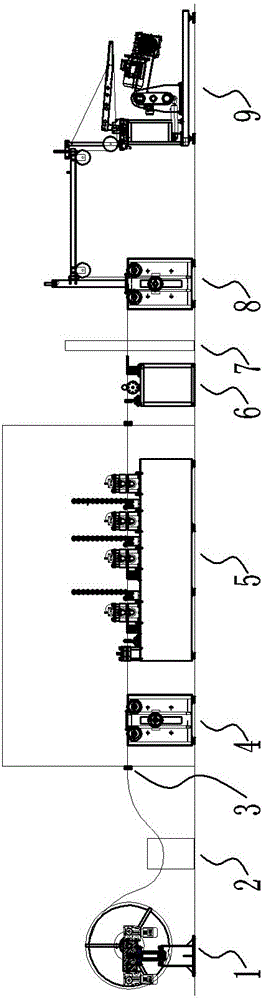

[0034] Such as figure 1 As shown, an uncoiler 1, a welding machine 2, a storage tensioning device 4, a rolling shear press unit 5, a length detection and camera system 6, a measuring device 7, an outlet storage swing device 8 and a coiler 9 are arranged in sequence, Flat guide rollers 3 are provided between the welding machine 2 and the inlet storage device, and between the rolling shear press unit 5 and the length detection and photographing system 6 . The raw material of the skeleton of the automobile weather strip must first be uncoiled by the uncoiler 1.

[0035] Such as Figures 3 to 5 The shown uncoiler 1 includes a bracket for supporting placement on the ground and a tensioning mechanism arranged on the bracket, and also includes a bearing housing 103 and a rotating shaft 107 located at the center of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com