A bamboo mat bamboo slice angle cutting machine

An angle cutting machine and bamboo chip technology, applied in mechanical equipment, sugarcane machining, manufacturing tools, etc., can solve the problems of unstable output quality, poor positioning ability of bamboo mats, and reduced quality of finished products, and achieve continuous output quality. The effect of uniformity, good corner cutting output quality, and stable bamboo slice position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

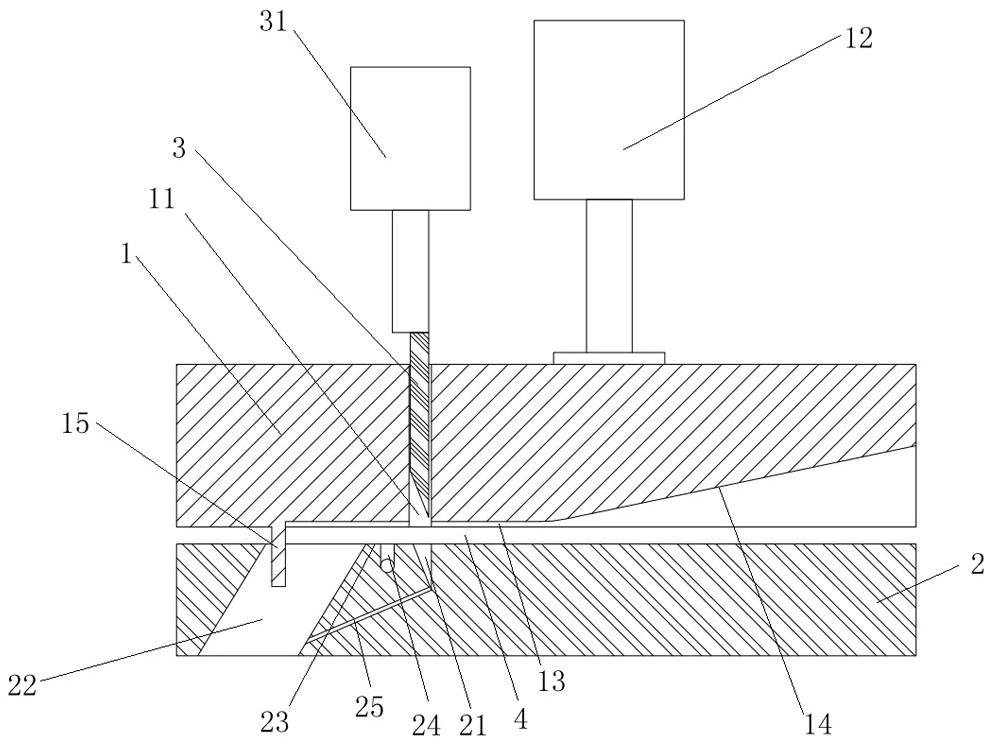

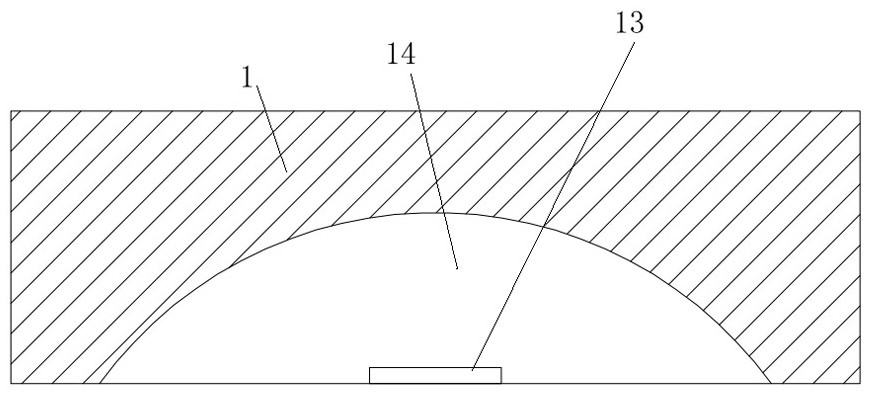

[0027] Such as figure 1 , 2 A kind of bamboo mat bamboo slice angle cutting machine shown in , 4, comprise upper die base 1 and lower die base 2 that are arranged side by side up and down and are the feed end that enters by bamboo slice and extend to downstream direction, upper die base 1 There is a knife groove 11 that accommodates the cutter 3 and is penetrated from top to bottom. The top of the cutter 3 is connected to a vertically downward angle-cutting cylinder 31 , and can move up and down in the knife groove 11 under the action of the angle-cutting cylinder 31 . Between the lower surface of the upper mold base 1 and the upper surface of the lower mold base 2, a shear space 4 for the passage of bamboo chips is formed, and the lower mold base 2 has a support groove 21 corresponding to the knife groove 11. When cutting corners, the bamboo chips Insert into the shearing space 4 from the feed end until the end of the unprocessed bamboo slices passes below the cutter 3 when ...

Embodiment 2

[0038] The technical scheme described in embodiment two is similar to embodiment one, and its difference is:

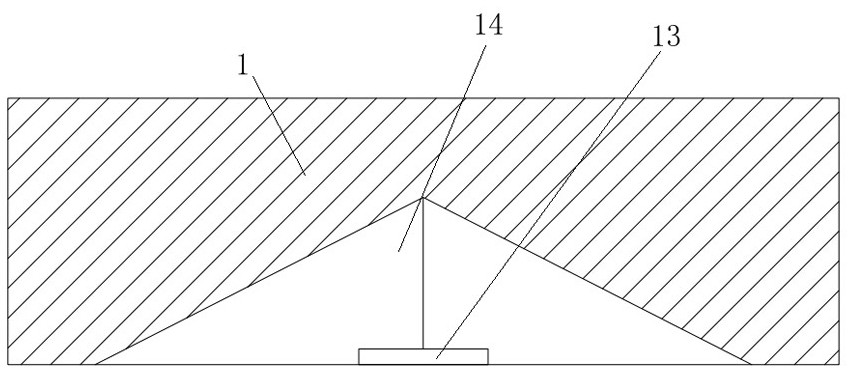

[0039] Such as image 3 As shown, the cross-sectional shape of the guide section 14 perpendicular to the upstream and downstream directions is an isosceles triangle. Thereby it is guided by the ends of the bamboo slices on both sides of its symmetry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com