Double network reinforced calcium alginate fiber and its preparation method

A calcium alginate fiber, reinforced technology, applied in the chemical characteristics of fibers, spinning solution preparation, wet spinning and other directions, can solve problems such as low fiber strength, and achieve low processing energy consumption, obvious enhancement effect, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This embodiment discloses a double network reinforced calcium alginate fiber, which is prepared by the following method:

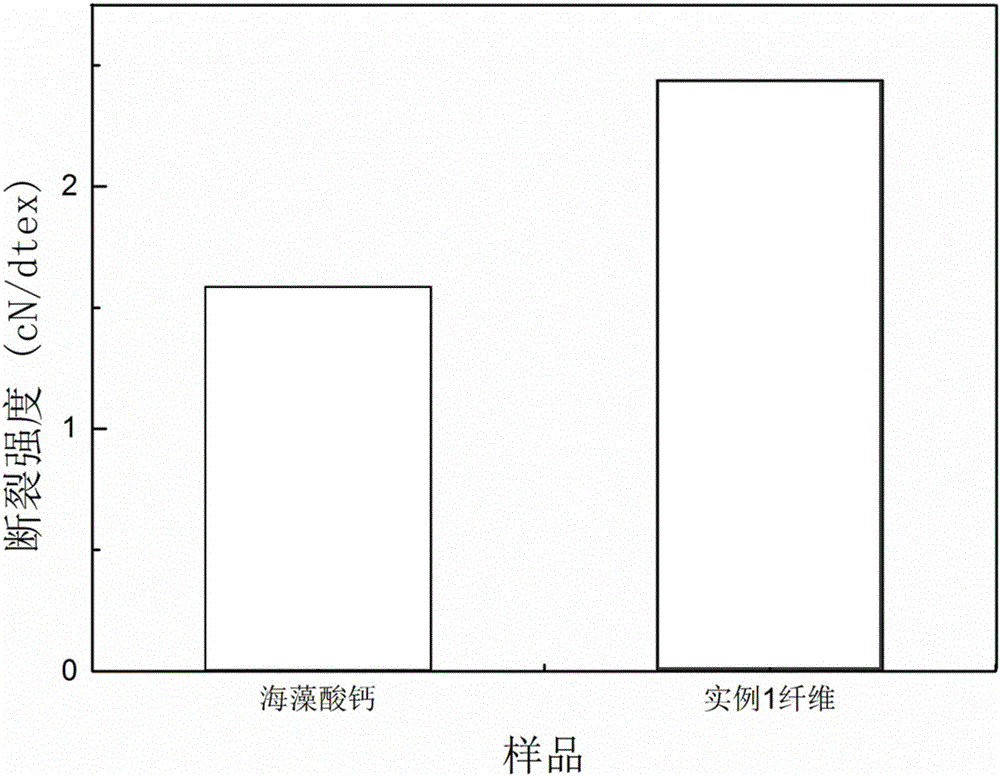

[0026] Dissolve 4g of sodium alginate, 0.8g of acrylamide, 0.32g of N,N-methylenebisacrylamide and 0.0083g of ammonium persulfate in 200ml of deionized water, react in a water bath at 50°C for 2.5h, and let stand after the reaction is complete Degassing, extruding into 2% calcium chloride aqueous solution, taking out the fibers after curing and molding, drawing and drying to obtain network-reinforced calcium alginate fibers. The breaking strength of double network reinforced calcium alginate fibers is 2.44cN / dtex.

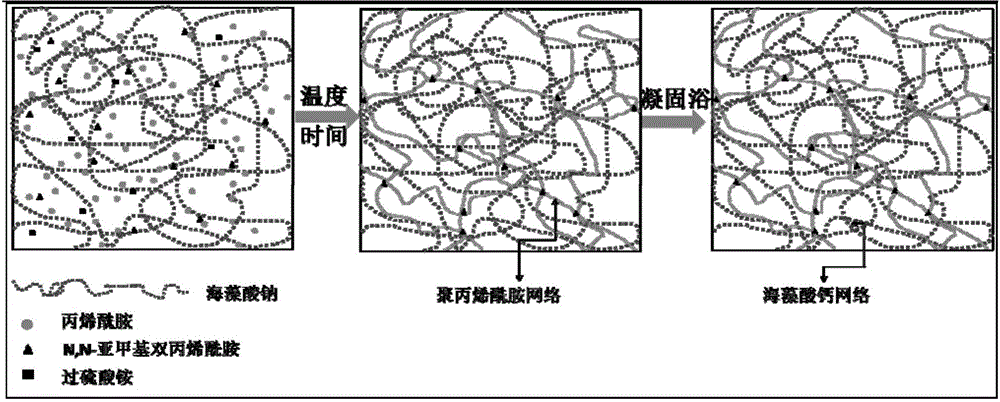

[0027] The structure and preparation process of the double network reinforced calcium alginate fiber in this embodiment are as follows: figure 1 As shown, the preparation process of the network-reinforced calcium alginate fiber in this example is as follows: acrylamide and N,N-methylenebisacrylamide copolymerize to form a covalent cross...

Embodiment 2

[0030] This embodiment discloses a double network reinforced calcium alginate fiber, which is prepared by the following method:

[0031] Dissolve 2g of sodium alginate, 0.2g of acrylamide, 0.02g of N,N-methylenebisacrylamide and 0.0021g of ammonium persulfate in 200ml of deionized water, and react in a water bath at 45°C for 1 hour. foam, extrude into 2% calcium chloride aqueous solution, take out the fiber after curing and molding, draw and dry to obtain network-reinforced calcium alginate fiber.

[0032] The breaking strength of the double network reinforced calcium alginate fiber prepared in this example is 1.34cN / dtex.

Embodiment 3

[0034] This embodiment discloses a double network reinforced calcium alginate fiber, which is prepared by the following method:

[0035] Dissolve 3g of sodium alginate, 0.45g of acrylamide, 0.08g of N,N-methylenebisacrylamide and 0.0053g of ammonium persulfate in 200ml of deionized water, and react in a water bath at 60°C for 3 hours. foam, extrude into 2% calcium chloride aqueous solution, take out the fiber after curing and molding, draw and dry to obtain network-reinforced calcium alginate fiber.

[0036] The breaking strength of the double network reinforced calcium alginate fiber prepared in this example is 2.24cN / dtex.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com