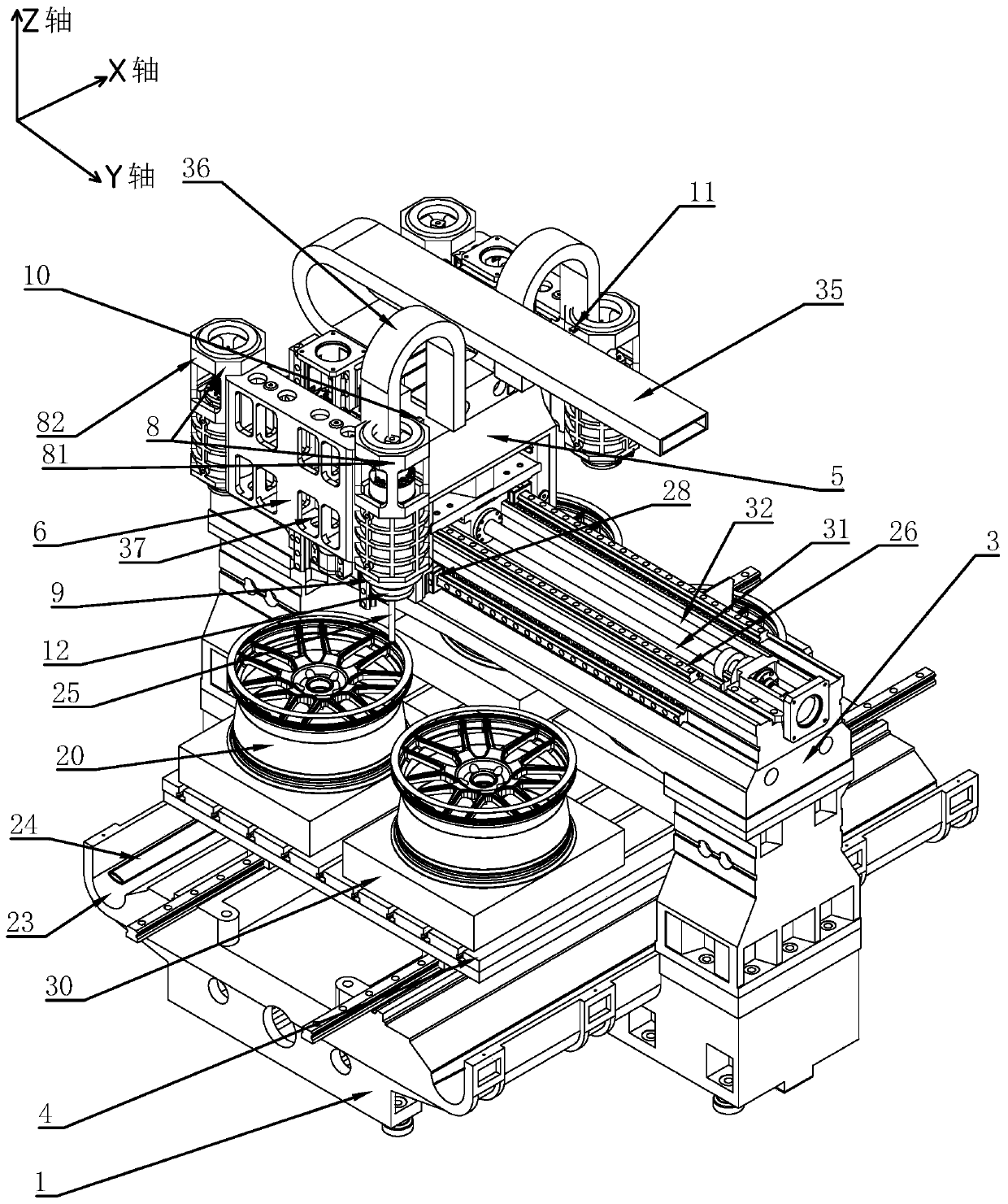

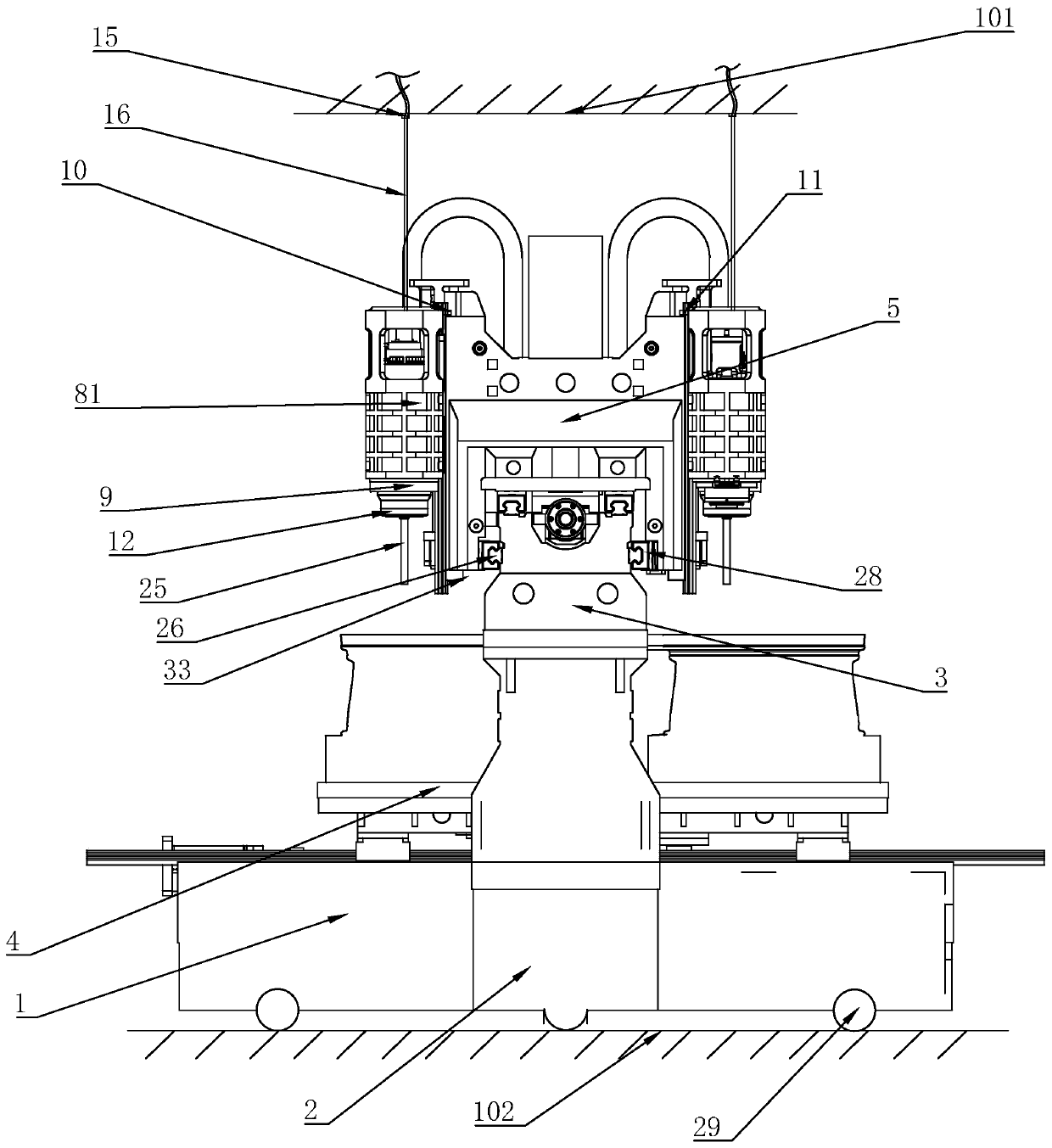

Four-spindle machining center special machine capable of clearing debris automatically

A technology of spindle processing and automatic cleaning, which is applied in the direction of metal processing machinery parts, metal processing, metal processing equipment, etc., can solve the problems of processing influence, debris splashing, affecting workpiece quality, etc., and achieve the effect of ensuring cleanliness and improving processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

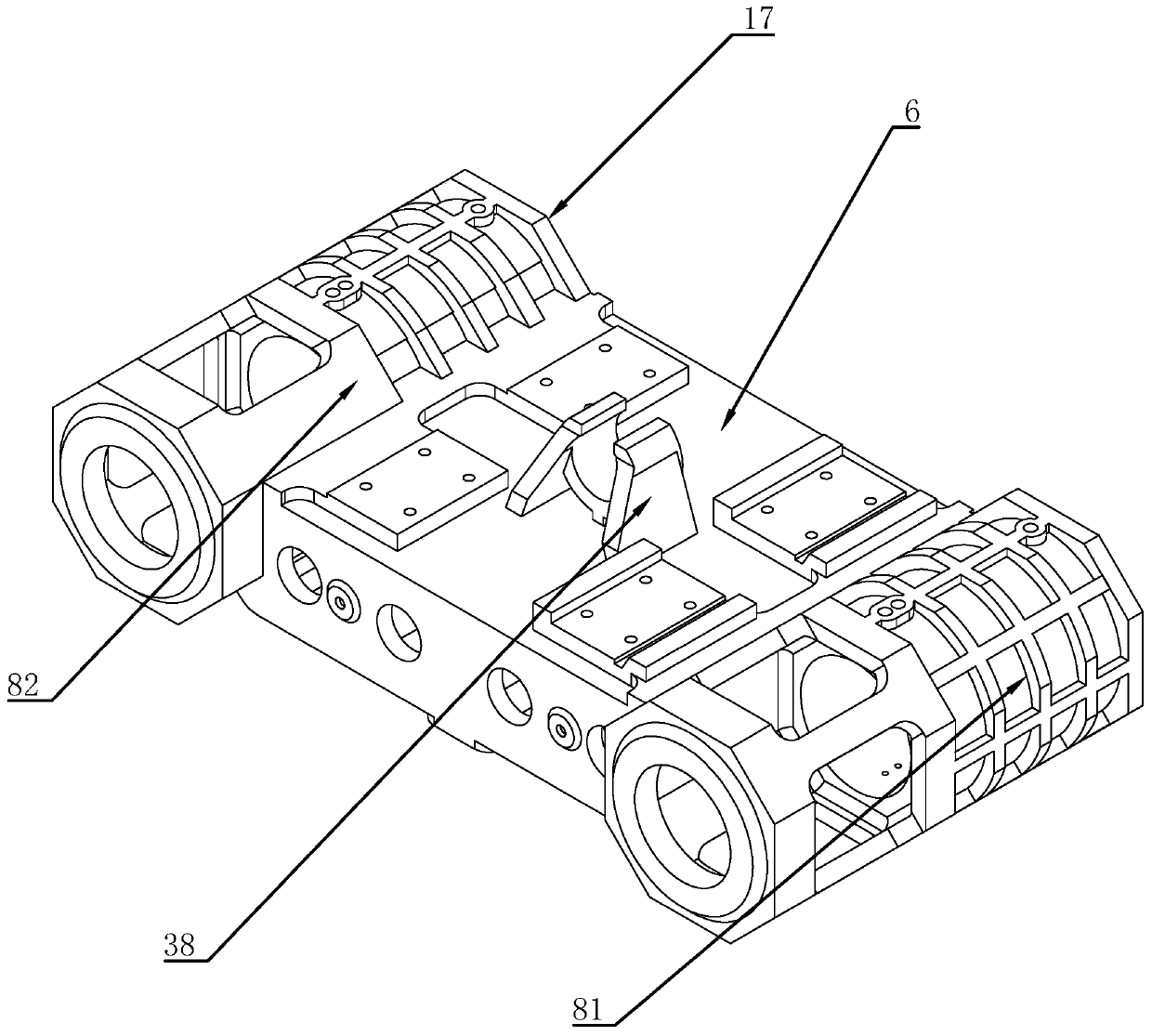

Method used

Image

Examples

Embodiment 2

[0065] Example 2 as Figure 1 to Figure 12 Shown: The difference from Example 1 is that two signal transmitters are respectively installed on the front spindle and rear spindle on one headstock, and two signal receivers are respectively installed on the opposite front spindle and rear spindle on the other side of the slide seat. When there are at least three signal receivers receiving the signals from the corresponding signal transmitters, the work will proceed normally.

[0066]The difference from the principle of Embodiment 1 is that the corresponding signal transmitter 10 and the signal receiver 11 are at the same height in the initial state, and during the movement of the front main shaft 9 and the rear main shaft 9 to the Z-axis direction, one of the front main shaft seats There are respectively two signal transmitters 10 on one of the rear main shaft seats, and these four signal transmitters 10 can emit signals all the time. The two signal receivers 11 can receive signa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com