Concrete continuous rigid frame bridge assembly type partial load prevention pushing device and construction method thereof

A technology of jacking devices and rigid frame bridges, which is applied in erecting/assembling bridges, bridges, bridge construction, etc. It can solve problems such as difficult synchronization, uneven structural stress, complicated installation and disassembly, and avoid instability. , easy control, enhanced stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and implementation cases.

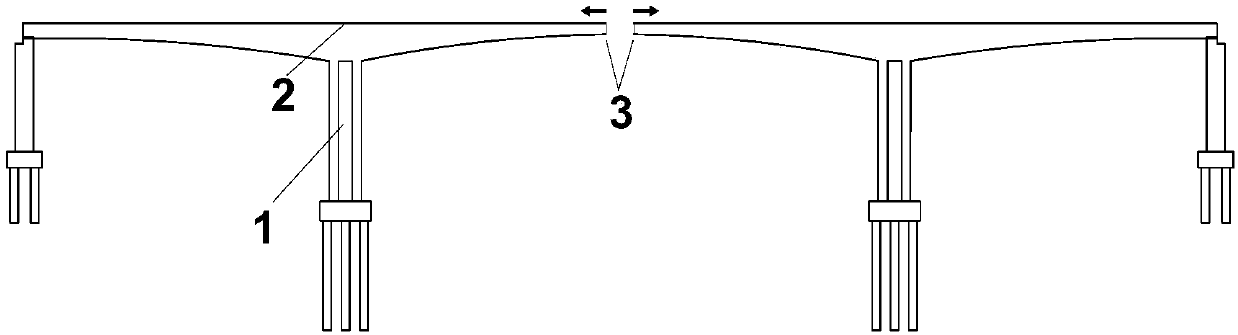

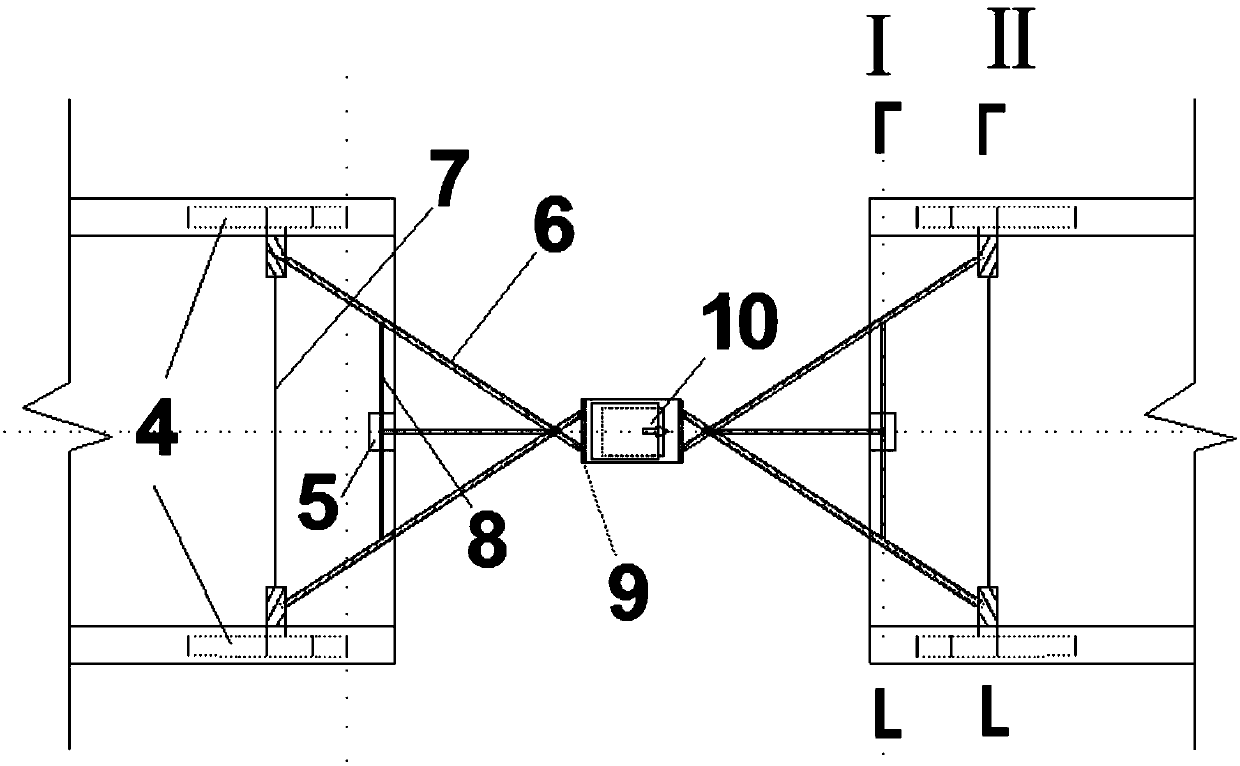

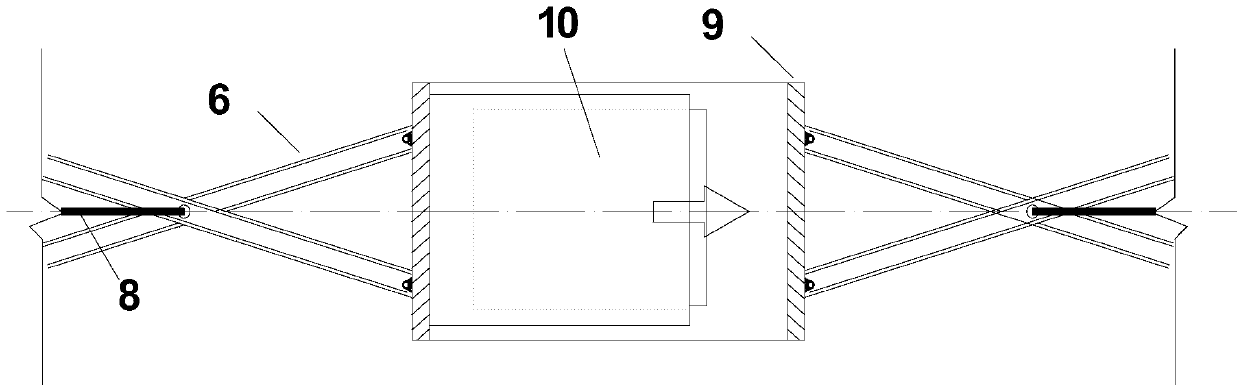

[0029] like figure 2 As shown, a concrete continuous rigid-frame bridge assembled anti-eccentric load jacking device includes an embedded part, a force transmission rod and a power system.

[0030] The power system includes a jack 10, an oil pump and two L-shaped pressure-bearing plates 9, the two pressure-bearing plates 9 are arranged oppositely, the jack 10 is installed between the two L-shaped pressure-bearing plates 9, and a jacking force is applied by the oil pump; The L-shaped bearing plates 9 are respectively connected with the embedded parts on the beam bodies on both sides of the middle span of the continuous rigid frame bridge through two sets of force transmission rods.

[0031] like figure 2 , Figure 4 , Figure 5 As shown, the embedded parts include two web embedded parts 4 and one roof embedded part 5. The two web embedded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com