Method for preparing biological natural gas from marsh gas

A technology of natural gas and biogas, which is applied in the direction of gas fuel, petroleum industry, fuel, etc., can solve the problems of limited use, low use value, and the work of biogas concentration has not been carried out, so as to increase the scope of use, increase the price, and increase the use value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

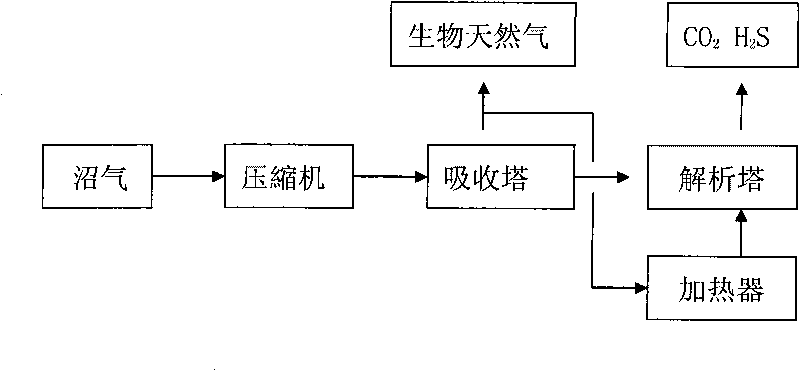

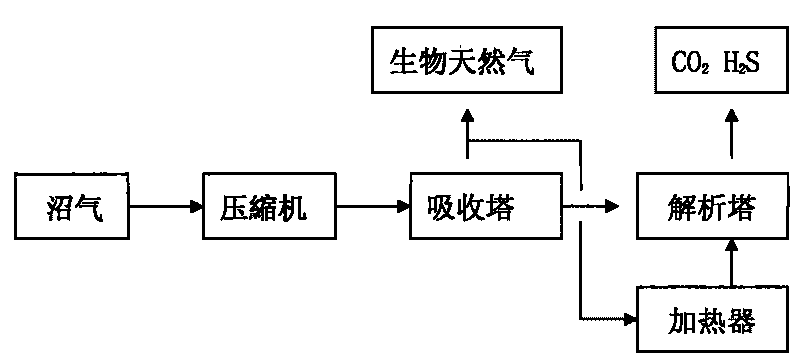

Method used

Image

Examples

Embodiment 1

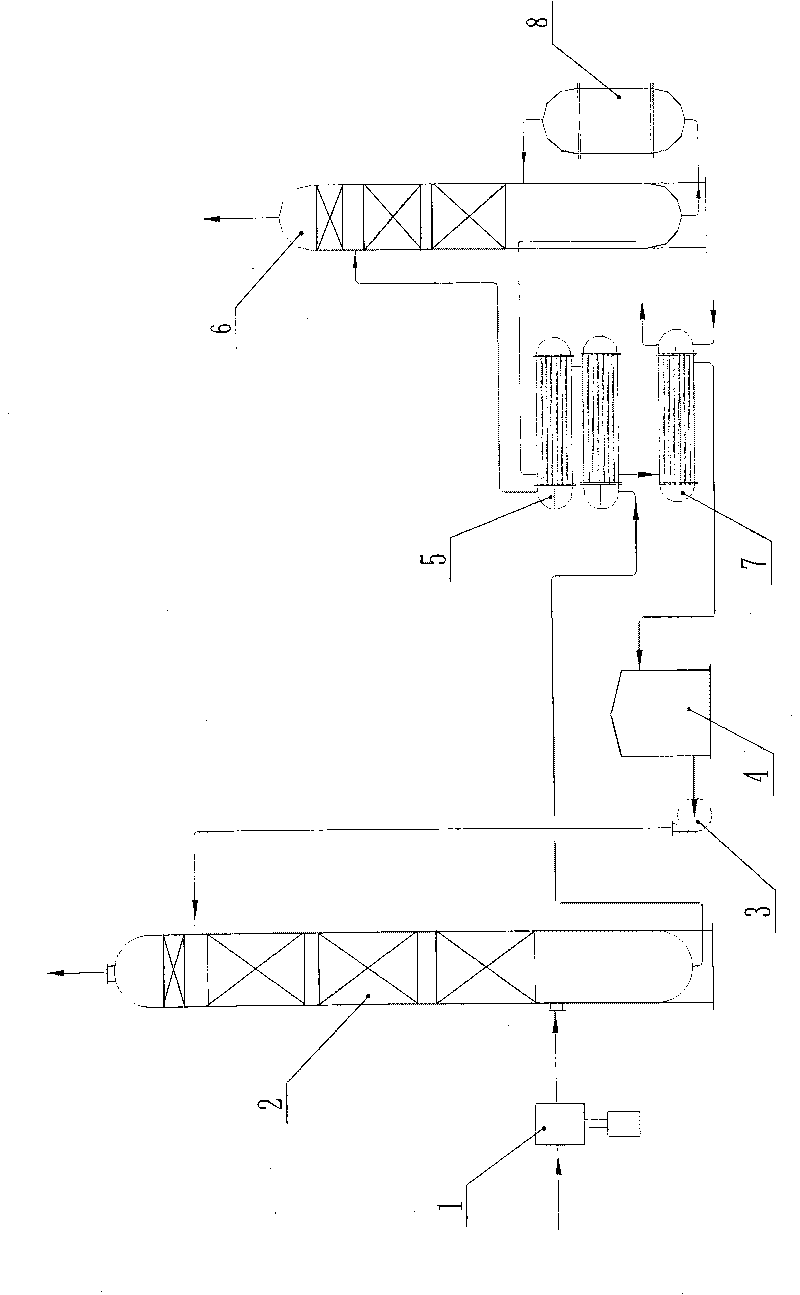

[0026] Such as figure 2 As shown, the biogas is pressurized to 0.35mpa with compressor 1, and enters the absorption tower 2 (biogas volume 100m 3 / h), use the circulating pump 3 to send the lean liquid in the lean liquid tank 4 to the top of the absorption tower and spray it down, and the biogas is in countercurrent contact with the absorbent-ethanolamine solution from the bottom up to absorb the CO 2 、H 2 S, from the top of the absorption tower is the purified bio-natural gas.

[0027] The rich liquid from the absorption tower enters the desorption tower 6 after heat exchange by the heat exchanger 5, and the desorption liquid at the bottom of the desorption tower is heated to 105-115°C by the heater 8, and the rich liquid decomposes in the desorption tower to release CO 2 、H 2 S, the lean solution after analysis is cooled by heat exchange, and then cooled with water to below 35°C for recycling. The monoethanolamine solution is a monoethanolamine aqueous solution with a m...

Embodiment 2

[0029] The biogas is pressurized to 0.7mpa with compressor 1, and enters the absorption tower 2 (biogas volume 100m 3 / h), use the circulating pump 3 to send the lean liquid in the lean liquid tank 4 to the top of the absorption tower and spray it down, and the biogas is in countercurrent contact with the absorbent-ethanolamine solution from the bottom up to absorb the CO 2 、H 2 S, from the top of the absorption tower is the purified bio-natural gas.

[0030] The rich liquid from the absorption tower enters the desorption tower 6 after heat exchange by the heat exchanger 5, and the desorption liquid at the bottom of the desorption tower is heated to 105-115°C by the heater 8, and the rich liquid decomposes in the desorption tower to release CO 2 、H 2 S, the lean solution after analysis is cooled by heat exchange, and then cooled with water to below 35°C for recycling. The monoethanolamine solution is a monoethanolamine aqueous solution with a mass percentage concentration o...

Embodiment 3

[0032] The biogas is pressurized to 0.5mpa with the compressor 1, and enters the absorption tower 2 (the biogas volume is 500m 3 / h), use the circulating pump 3 to send the lean liquid in the lean liquid tank 4 to the top of the absorption tower and spray it down, and the biogas is in countercurrent contact with the absorbent-ethanolamine solution from the bottom up to absorb the CO 2 、H 2 S, from the top of the absorption tower is the purified bio-natural gas.

[0033] The rich liquid from the absorption tower enters the desorption tower 6 after heat exchange by the heat exchanger 5, and the desorption liquid at the bottom of the desorption tower is heated to 105-115°C by the heater 8, and the rich liquid decomposes in the desorption tower to release CO 2 、H 2 S, the lean solution after analysis is cooled by heat exchange, and then cooled with water to below 35°C for recycling. The monoethanolamine solution is a monoethanolamine aqueous solution with a mass percent concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com