Method for treating antibiotic dregs by adopting thermophilic microbial agent

A thermophilic microorganism and antibiotic technology, applied in the field of biodegradation, to achieve the effect of high reduction, low investment cost and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

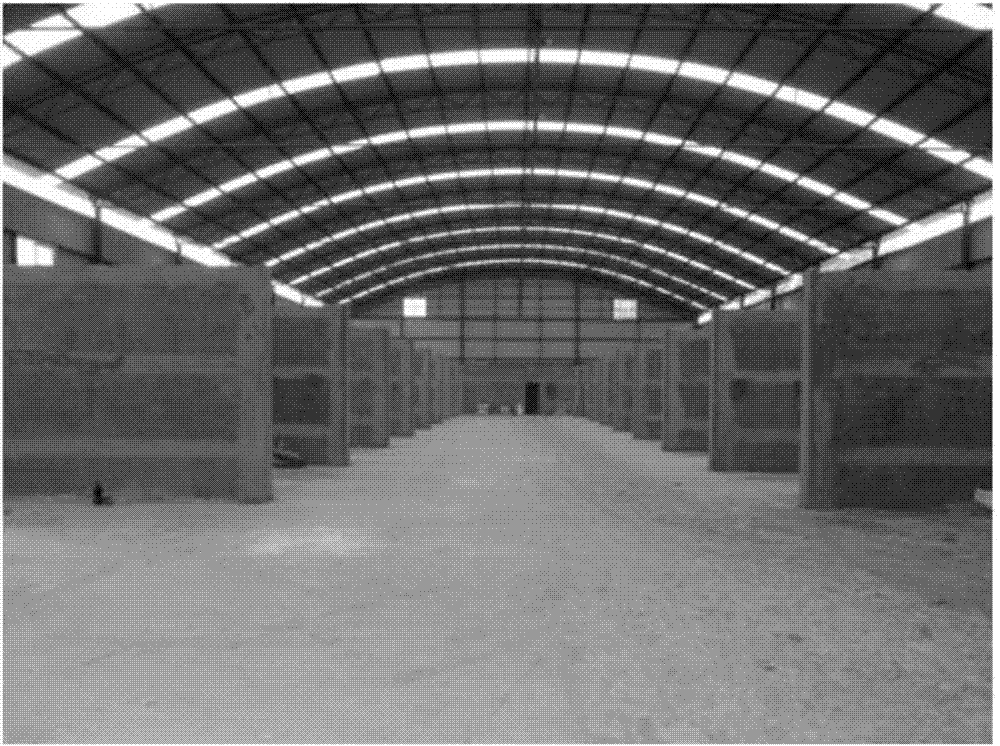

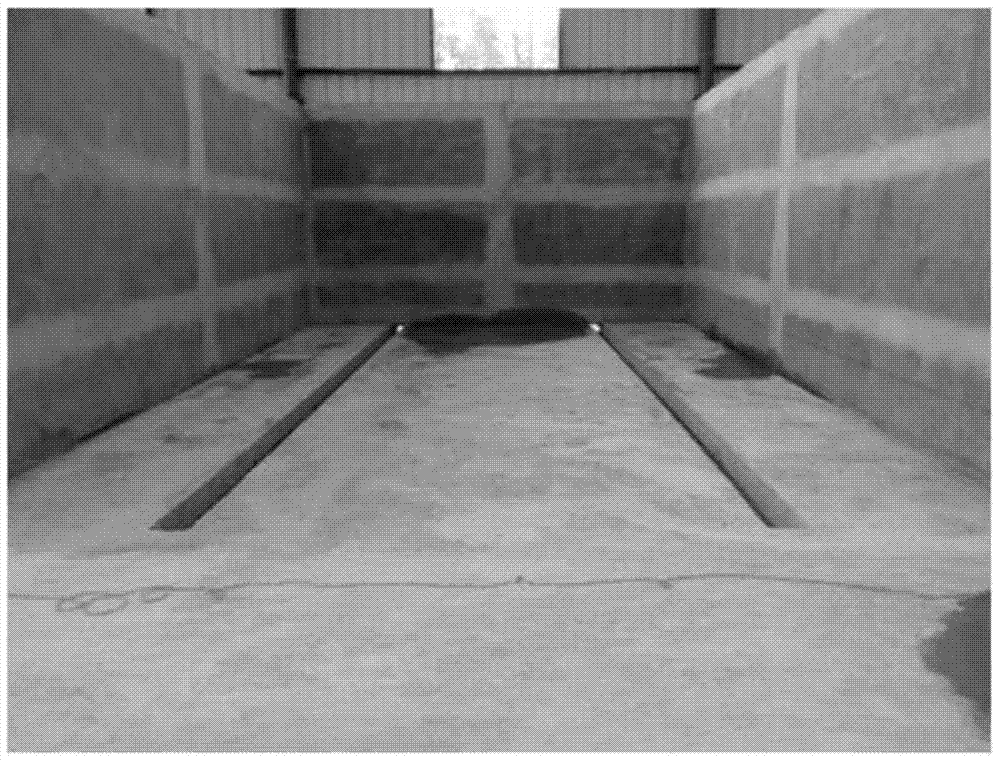

Image

Examples

Embodiment 1

[0027] Embodiment 1 is used for processing the thermophilic microbial composite bacterial agent of antibiotic scum and its preparation

[0028] The active ingredients in the composite microbial agent include Geobacillus sp. UTM01 with a preservation number of CGMCC No.5641, Geobacillus sp. UTM02 with a preservation number of CGMCC No.5642, and Bacillus sp. UTM03 with CGMCC No.5643, Bacillus methylotrophicus UTM401 with CGMCC No.5927, Anoxybacillus sp. with CGMCC No.5928 mongoliensis) UTM501 and thermophilic facultative bacillus (Anoxybacillus pushchinoensis) UTM601 with the preservation number CGMCC No.5929, both of which are microorganisms screened from high temperature environments.

[0029] The number of viable bacteria in the thermophilic microbial compound bacterial agent is ≥1×10 11 CFU / mL.

[0030] Slant medium: 10g peptone, 10g yeast extract, 10g sodium chloride, 16-20g agar, 1000mL water, natural pH.

[0031] Seed medium: peptone 10g, yeast extract 10g, sodium chlori...

Embodiment 2

[0036] The processing of embodiment 2 cephalosporin slag

[0037] 40 tons of cephalosporin C (CPC) fungus residue was shipped from a company, with a water content of about 75%, of which about 42.9 crude protein, 2.9 crude fat, 38.1 sugar, 3.5 crude fiber and 3.5 crude fiber per gram of dry weight (%) Ash powder 8.7; Among them, calcium 2.2, phosphorus 1.3; amino acid content see Table 1. The cephalosporin content was 2414ppm. Add 20 tons of moisture regulator (water content about 30%), mix well, and the water content of this material is about 60%. Add 40L of the thermophilic microbial bacterial agent prepared in Example 1 and further mix evenly. Stack aerobic fermentation in the fermenter. On the 1st to 3rd day, the ventilation volume is low, the full volume is 700m 3 1 / 3 to 1 / 4 of the air volume per hour, increase the air volume to 1 / 2 to 1 of the full volume after the 4th day, and the full volume to the end of fermentation after 8 days.

[0038] Detect the temperature o...

Embodiment 3

[0044] The processing of embodiment 3 oxytetracycline slag

[0045] 21 tons of oxytetracycline fungus residues were shipped from a certain company, with a water content of about 72%, of which each g dry weight (%) contained about 44.7 crude protein, 1.1 crude fat, 36.2 sugar, 4.3 crude fiber, and 10.1 coarse ash; Among them, calcium 5.2, phosphorus 0.3; amino acid content is shown in Table 3. The content of oxytetracycline in oxytetracycline bacteria residue is 1103ppm. Add 10 tons of moisture regulator (water content about 30%), mix well, and the water content of this material is about 58%. Add 21L of the thermophilic microbial bacterial agent prepared in Example 1 and then further mix evenly. Use a forklift to transport to the fermentation tank for stacking aerobic fermentation. On the 1st to 4th day of aerobic fermentation, the ventilation rate is as low as 700m 3 1 / 3 to 1 / 4 of the / h, increase the air volume to 1 / 2 to 1 of the full amount after the 5th day, and increas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com