Method for preparing graphene through photo-catalysis

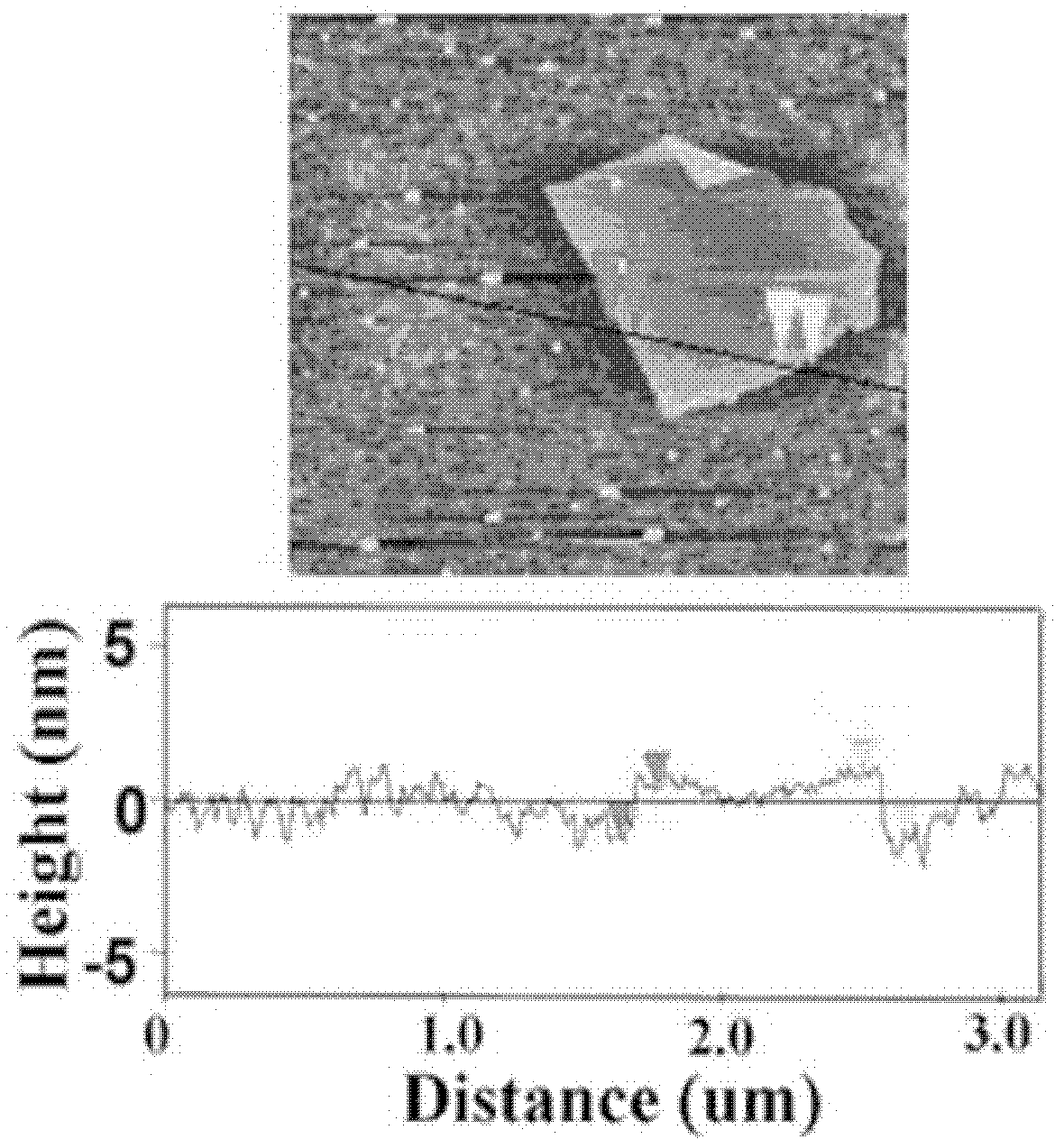

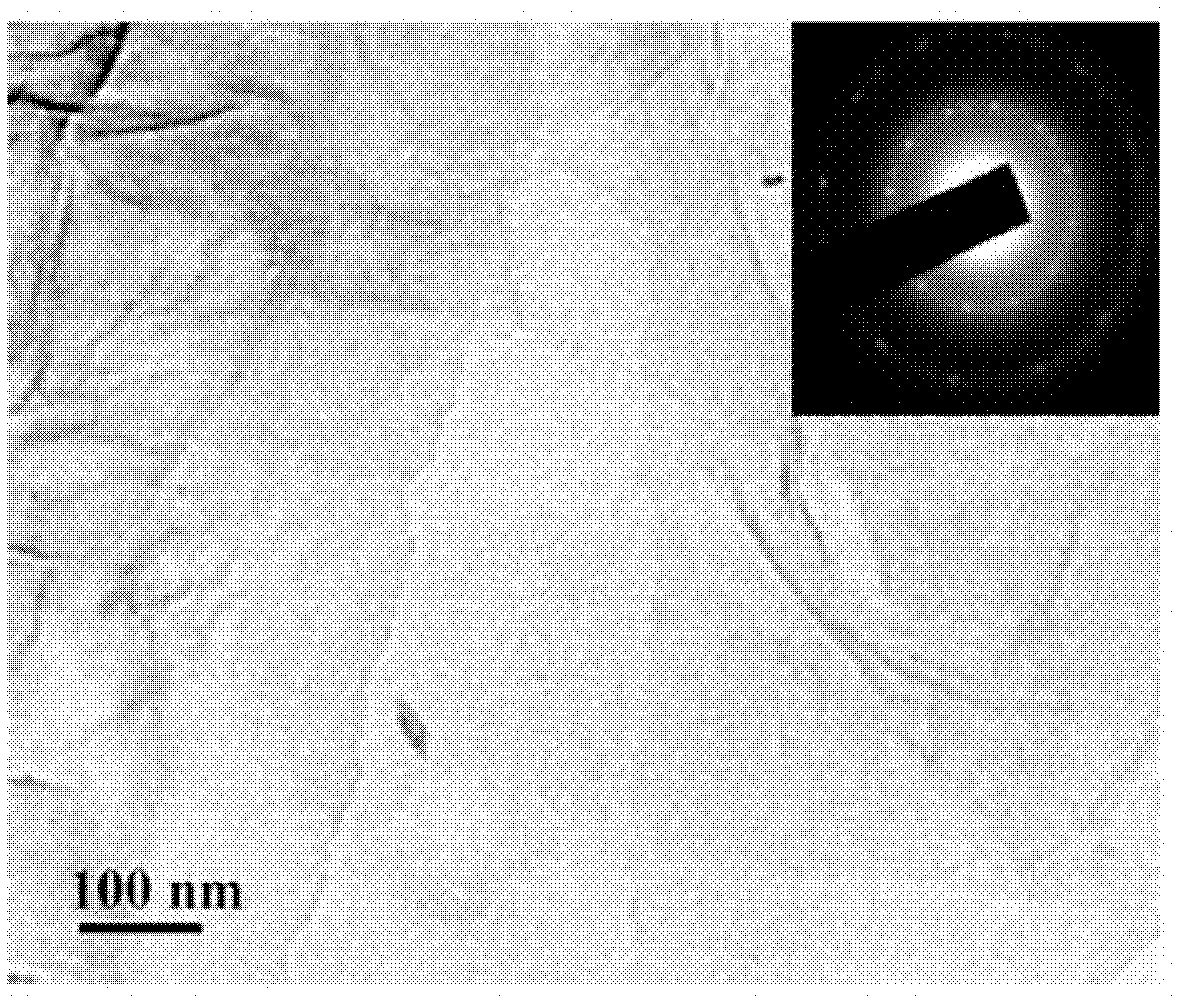

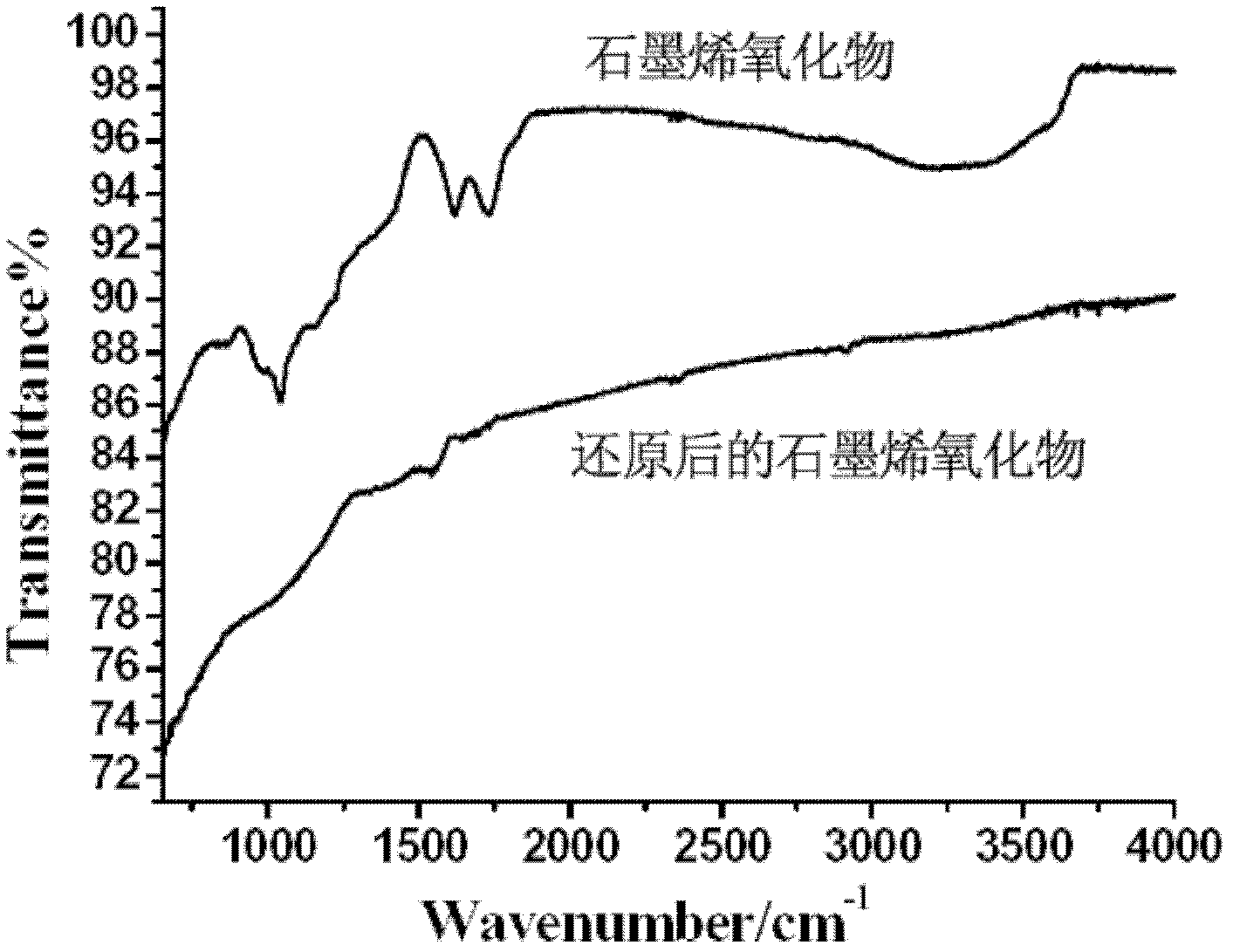

A photocatalysis, graphene technology, applied in the direction of graphene, nano carbon, etc., can solve the problems of difficult control of reduction degree, low reduction degree, and easy cracking of graphene film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] A method for photocatalytically preparing graphene, comprising the steps of:

[0097] 1) Expansion treatment of graphite:

[0098] Heat 9mL of concentrated sulfuric acid to 80°C, add 1.6g of potassium peroxodisulfate and 1.6g of phosphorus pentoxide, stir at this temperature to completely dissolve the solid, then slowly add 2g of 325-mesh flake graphite, and complete the addition within 5 minutes ; The mixture was reacted at 80°C for 4.5 hours, cooled to room temperature after the reaction, and then added with 350mL of deionized water. After standing for 12 hours, the mixture was filtered through a 0.2μm filter membrane, and the residual acid was washed with a large amount of water; The solid was left at room temperature for 12 hours;

[0099] 2) Oxidation of expanded graphite:

[0100] Take 80mL of concentrated sulfuric acid and place it in an ice bath at 0°C, add the expanded graphite obtained in step 1) to the sulfuric acid solution, then slowly add 10g of potassiu...

Embodiment 2

[0106] Repeat Example 1, its difference is only: in step 4), described 1,4-dihydropyridine derivative (R 1 = H, R 2 =R 3 =COOEt,R 4 =H) was 35 mg.

Embodiment 3

[0108] Repeat Example 1, its difference is only: in step 3) in, the concentration of the aqueous solution of described eosin Y is 1.5 * 10 -3 mol / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com