Preparation method of metal catalyst with high selectivity and high dispersion

A metal catalyst, high selectivity technology, applied in catalyst activation/preparation, molecular sieve catalysts, chemical instruments and methods, etc., can solve problems such as waste water generation, unfriendly environment, environmental impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the embodiments shown in the accompanying drawings.

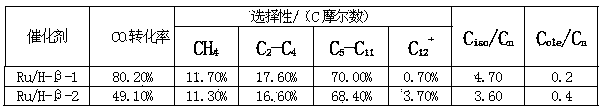

[0017] The size of gasoline anti-knock ability is related to chemical composition. Aromatics have the best shock resistance (that is, the least knocking), followed by naphthenes and branched isoparaffins, followed by olefins, and normal (linear) alkanes in alkanes have the lowest shock resistance. However, aromatic hydrocarbons in gasoline components can easily produce carcinogens due to incomplete oxidative combustion, causing pollution to the environment. Therefore, the target Fischer-Tropsch synthesis products are mainly naphthenes and branched isoparaffins.

[0018] 1. Preparation of base metal catalysts: use different base metal (such as Cu, Ag, Au, Ni, Co, Fe) precursors (nitrate or acetate and other salts containing the above metal elements) and organic acids containing carboxyl groups (such as formic acid , acetic acid, pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com