Pavement brick produced from industrial waste residues and production method thereof

A technology of industrial waste residues and production methods, which is applied in the field of building materials, can solve the problems of insufficient resource utilization of industrial waste residues, exhaustion of natural resources of building materials, etc., and achieve the effects of high compressive strength, enhanced strength, and improved dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

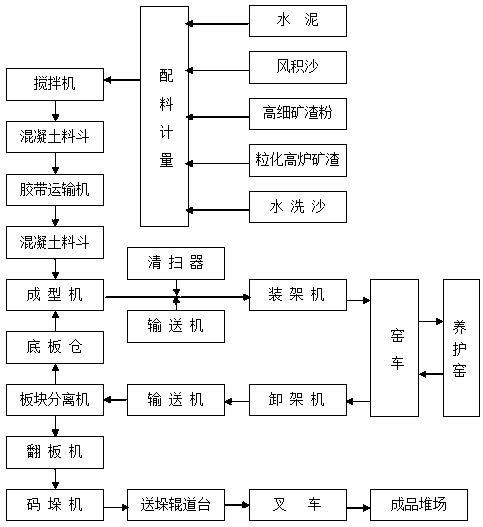

Image

Examples

Embodiment 1

[0028] Embodiment 1. A pavement brick produced by industrial waste slag is characterized in that it contains the following components by weight percentage: 37% of granulated blast furnace slag (particle size not greater than 6mm), high fine slag powder (specific surface area not less than 420cm² / g) 7%, aeolian sand 20%, washed sand 16%, and the balance is cement.

[0029] The production method comprises the following steps:

[0030] Step 1. Prepare raw materials: Granular raw materials are transported into the factory by car, and after passing the sampling test, they are stored in five raw material storage sheds with a storage capacity of about 2000 tons each; powder raw materials are directly pumped into a steel silo with a storage capacity of 100 tons for storage.

[0031] Step 2. Screening and mixing: install electric vibrating screens on various raw material batching bins, screen out agglomerated or large particle materials during the loading process of the forklift, and ...

Embodiment 2

[0035] Embodiment 2, a pavement brick produced by industrial waste slag, is characterized in that it contains the following components by weight percentage: 30% of granulated blast furnace slag (particle size not greater than 6mm), high fine slag powder (specific surface area not less than 420cm² / g) 15%, aeolian sand 22%, washed sand 22%, and the balance is cement.

[0036] The production method comprises the following steps:

[0037] Step 1. Prepare raw materials: Granular raw materials are transported into the factory by car, and after passing the sampling test, they are stored in five raw material storage sheds with a storage capacity of about 2000 tons each; powder raw materials are directly pumped into a steel silo with a storage capacity of 100 tons for storage.

[0038] Step 2. Screening and mixing: install electric vibrating screens on various raw material batching bins, screen out agglomerated or large particle materials during the loading process of the forklift, an...

Embodiment 3

[0042] Embodiment 3, a pavement brick produced by industrial waste slag, is characterized in that it contains the following components by weight percentage: 33% of granulated blast furnace slag (particle size not greater than 6mm), high fine slag powder (specific surface area not less than 420cm² / g) 10%, aeolian sand 25%, washed sand 22%, and the balance is cement.

[0043] The production method comprises the following steps:

[0044] Step 1. Prepare raw materials: Granular raw materials are transported into the factory by car, and after passing the sampling test, they are stored in five raw material storage sheds with a storage capacity of about 2000 tons each; powder raw materials are directly pumped into a steel silo with a storage capacity of 100 tons for storage.

[0045] Step 2. Screening and mixing: install electric vibrating screens on various raw material batching bins, screen out agglomerated or large particle materials during the loading process of the forklift, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com