Technique method for directly producing sponge iron by carrying out deep reduction on extracted vanadium tailings

A technology for extracting vanadium tailings and a process method, applied in the direction of a fluidized bed furnace, etc., can solve the problems of extracting iron ore, low recovery rate, cumbersome process, etc., and achieve the effects of low price, easy control and large reserves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

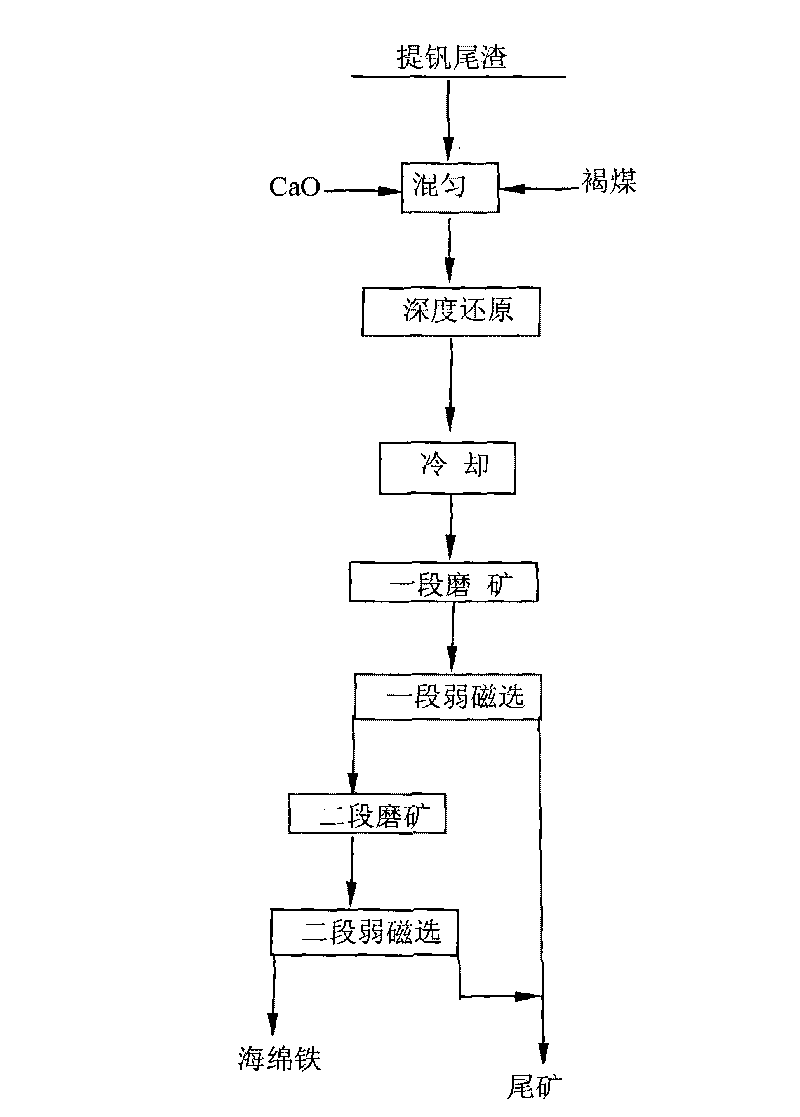

Image

Examples

Embodiment 1

[0009] Vanadium extraction tailings contain 36.51% iron and TiO 2 9.65% with Na 2 O 4.38%. The deep reduction conditions are: vanadium extraction tailings: lignite: CaO = 100: 40: 15, after mixing, reduce and roast in a muffle furnace at 1100 ° C for 40 minutes; 87% magnetic separation at a magnetic field strength of 80kA / m. The magnetic separation products account for about 90% when the grinding concentration is 55% to -0.030mm, and the sponge iron is obtained by magnetic separation under the condition of the magnetic field strength of 64kA / m. Obtained iron content of 90.85%, TiO 2 Sponge iron with a content of 0.17% and other impurities that meet the requirements of steelmaking.

Embodiment 2

[0011] Vanadium extraction tailings contain 32.84% iron and TiO 2 12.21% with Na 2 O 4.90%. The deep reduction conditions are: vanadium extraction tailings: lignite: CaO = 100: 30: 20, after mixing, reduce and roast in a muffle furnace at 1050 ° C for 50 min; 85%, magnetic separation at a magnetic field strength of 80kA / m. Magnetic separation products account for about 88% when the grinding concentration is 55% to -0.030mm, and sponge iron is obtained by magnetic separation under the condition of magnetic field strength of 64kA / m. Obtained iron content of 91.24%, TiO 2 Sponge iron with a content of 0.15% and other impurities that meet the requirements of steelmaking.

Embodiment 3

[0013] Vanadium extraction tailings contain 35.67% iron and TiO 2 10.15%, with Na 2 O 4.58%. The deep reduction conditions are: vanadium extraction tailings: lignite: CaO = 100:33:20, after mixing, reduce and roast in a muffle furnace at 1000 ° C for 60 minutes; cooling; grinding to a particle size of -0.074mm at a grinding concentration of 70% 88%, magnetic separation at a magnetic field strength of 80kA / m. The magnetic separation products account for about 90% when the grinding concentration is 55% to -0.030mm, and the sponge iron is obtained by magnetic separation under the condition of the magnetic field strength of 64kA / m. Obtained iron content of 91.64%, TiO 2 Sponge iron with a content of 0.14% and other impurities that meet the requirements of steelmaking.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com