Preparation method and product of sulphur black dye

A technology of sulfur black and dyes, applied in dyeing methods, organic dyes, textiles and papermaking, etc., can solve the problems of poor dyeing performance and low coloring rate, and achieve the effect of improving coloring rate, simple steps, and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

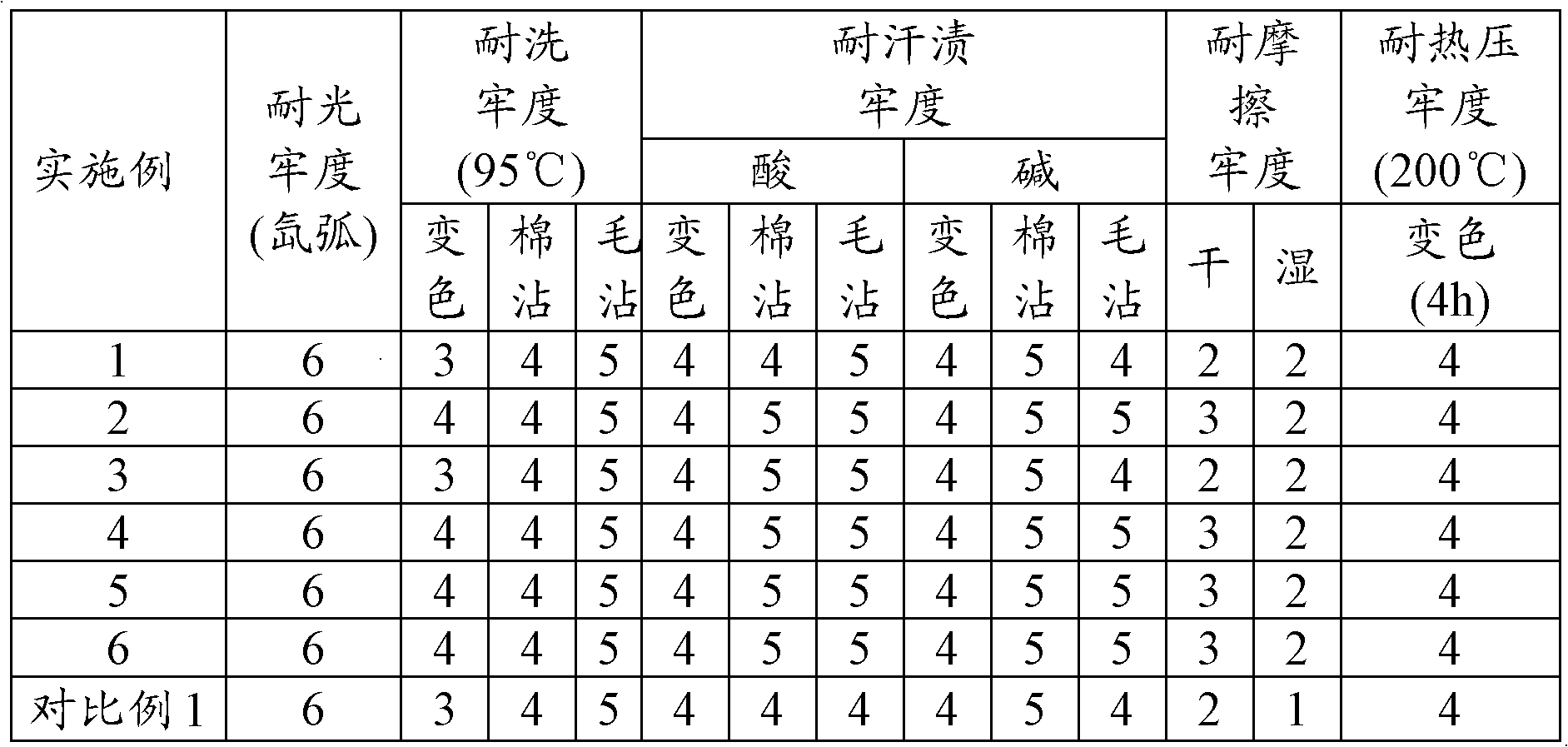

Examples

Embodiment 1

[0020] Add water and sulfur black intermediate filter cake 50g (dried 25g) into a 500mL beaker, heat up to 90°C, add 3.5g of sodium sulfide (60%), stir at 90-95°C for 30 minutes, then add Dispersant MF 0.5g, beating for 30 minutes until the whole is fluid, and spray drying to obtain 28.5g of sulfur black.

Embodiment 2

[0022] Add water and sulfur black intermediate filter cake 50g (dried 25g) into a 500ml beaker, heat up to 90°C, add 4g of sodium sulfide (60%), stir at 90-95°C for 40 minutes, then add dispersant to the slurry 2.5g of MF, stirred for 5min, and drum-dried to obtain 29.73g of sulfur black.

Embodiment 3

[0024] Add water and sulfur black intermediate filter cake 50g (dried 25g) into a 500ml beaker, heat up to 90°C, add 4.5g of sodium sulfide (60%), stir at 90-95°C for 45 minutes, then add 7.5g of dispersant MF, stirred for 10min, and dried to obtain 34.20g of sulfur black.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com