Water permeable brick and preparation method thereof

A technology of permeable bricks and cement, which is applied to the pavement, pavement details, and buildings paved with prefabricated blocks. It can solve the problems of lack of double-layer fabrics, save natural resources, improve economic and social benefits, and significantly improve social economy. and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] The steel slag is sieved to obtain the first steel slag and the second steel slag, wherein the particle size of the first steel slag is ≥3 mm and <5 mm, and the particle size of the second steel slag is 5-15 mm. The construction waste is sieved to obtain fine construction waste and coarse construction waste, wherein the particle size of the fine construction waste is ≤3 mm, and the particle size of the coarse construction waste is 5-15 mm.

[0081] Take fabric components in parts by weight: 15 parts of cement, 80 parts of first steel slag, 5 parts of fine construction waste and stir and mix for 30-40s, then add surface water reducer and surface water in turn and mix for 60-100s , to obtain a semi-dry topping mix. Wherein, the addition amount of surface layer water reducing agent is 0.5wt% of the amount of cement used, and the amount of surface layer water is 0.3 times of the amount of cement used.

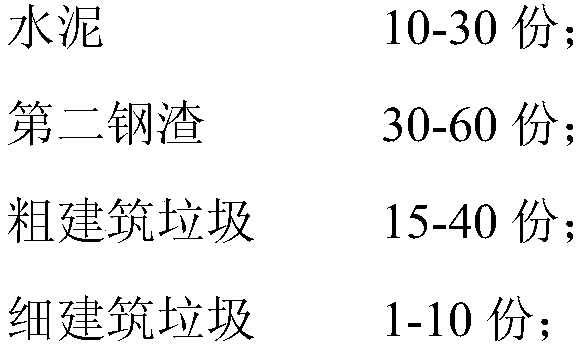

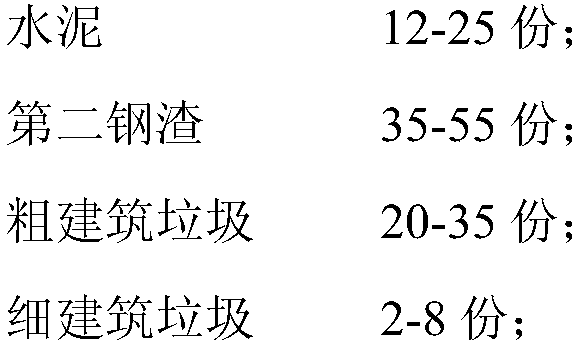

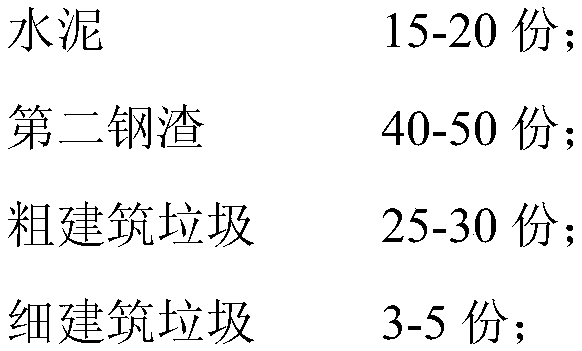

[0082] Take the base material components in parts by weight: 15 parts ...

Embodiment 2

[0086] The steel slag is sieved to obtain the first steel slag and the second steel slag, wherein the particle size of the first steel slag is 3-4 mm, and the particle size of the second steel slag is 5-8 mm. The construction waste is sieved to obtain fine construction waste and coarse construction waste, wherein the fine construction waste has a particle size of 1-3 mm, and the coarse construction waste has a particle size of 5-10 mm.

[0087] Take the fabric components in parts by weight: 20 parts of cement, 75 parts of the first steel slag, 5 parts of fine construction waste and stir and mix for 35 seconds, then add surface water reducer and surface water in turn and mix for 80 seconds to obtain semi-dry A durable topping mix. Wherein, the addition amount of surface layer water reducing agent is 0.5wt% of the amount of cement used, and the amount of surface layer water is 0.3 times of the amount of cement used.

[0088] Take the base material components in parts by weight:...

Embodiment 3

[0092] The steel slag is sieved to obtain the first steel slag and the second steel slag, wherein the particle size of the first steel slag is 4-4.9 mm, and the particle size of the second steel slag is 10-15 mm. The construction waste is screened to obtain fine construction waste and coarse construction waste, wherein the fine construction waste has a particle size of 0.5-2.5 mm, and the coarse construction waste has a particle size of 11-15 mm.

[0093] Take the fabric components in parts by weight: 18 parts of cement, 79 parts of the first steel slag, 3 parts of fine construction waste and stir and mix for 30 seconds, then add surface water reducer and surface water in turn and mix for 70 seconds to obtain semi-dry A durable topping mix. Wherein, the addition amount of the superplasticizer for the surface layer is 1.0wt% of the amount of cement, and the water for the surface layer is 0.2 times of the amount of cement.

[0094] Take the base material components in parts by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com