Treatment method for abamectin fermentation wastewater

A technology for fermenting waste water and abamectin, which is applied in natural water body treatment, water treatment parameter control, biological water/sewage treatment and other directions, can solve problems such as affecting the economic benefits of enterprises and endangering human health, etc., and achieves low cost and improved purification. Efficiency, the effect of obvious economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In a sterile environment, wipe the ampoule tube containing the Geotrichum candidum strain with absorbent cotton soaked in 75% alcohol, and heat the tip of the outer tube on a flame. Put a few drops of sterile water on the heating place to break the outer tube, knock off the top of the broken ampoule tube with a file or tweezers, and pass the opening of the lyophilized tube over the flame. Use a sterile pipette to draw 0.3-0.5 ml of liquid medium into the ampoule, and shake slightly until it is evenly suspended. Take 0.1-0.2ml of the bacteria suspension on the plate medium, separate and culture it by streaking or make a series of dilutions, and spread it evenly with a sterile L-shaped glass rod to test the purity and activation of the bacteria. Add 500 mL of distilled water, 5.0 g of glucose, 2.5 g of peptone, 1.5 g of yeast powder, and 1.5 g of malt extract to a 1L Erlenmeyer flask in a liquid medium. Bed culture for 40h. Centrifuge at 4000r / min and 4°C for 10 minutes...

Embodiment 2

[0040] (1) Adjust the abamectin fermentation wastewater to adjust the pH to 5.0;

[0041] (2) In the abamectin fermented waste water after step (1) treatment, drop Geotrichum candidum with 20% inoculation amount;

[0042] (3) Control the temperature at 20°C, the ventilation rate is 2.1L / min, and ferment for 72 hours;

[0043] (4) The avermectin fermentation wastewater treated in step (3) is subjected to solid-liquid separation, and the separated liquid phase is measured and calculated for COD removal rate, ammonia nitrogen removal rate, and total nitrogen removal rate.

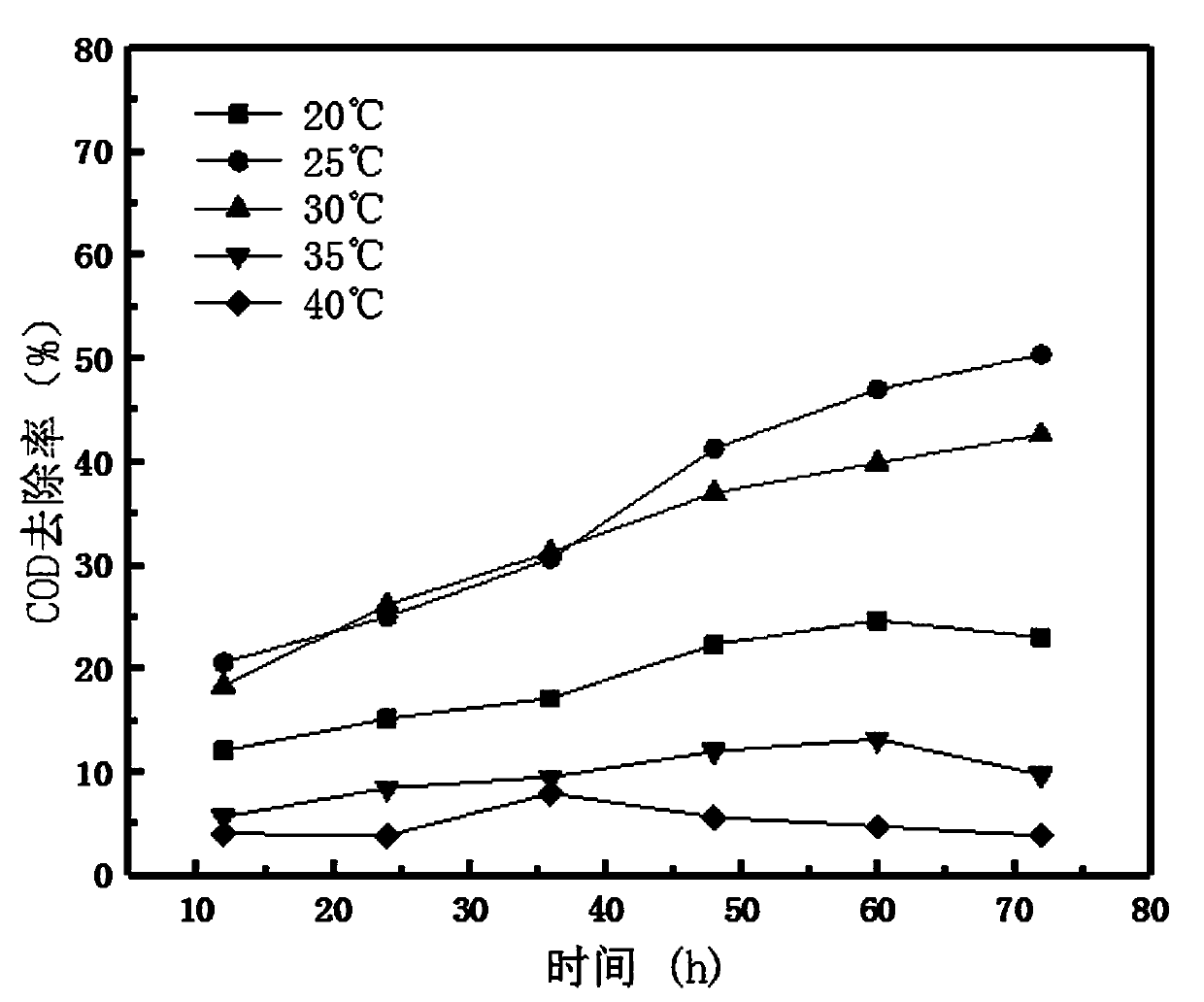

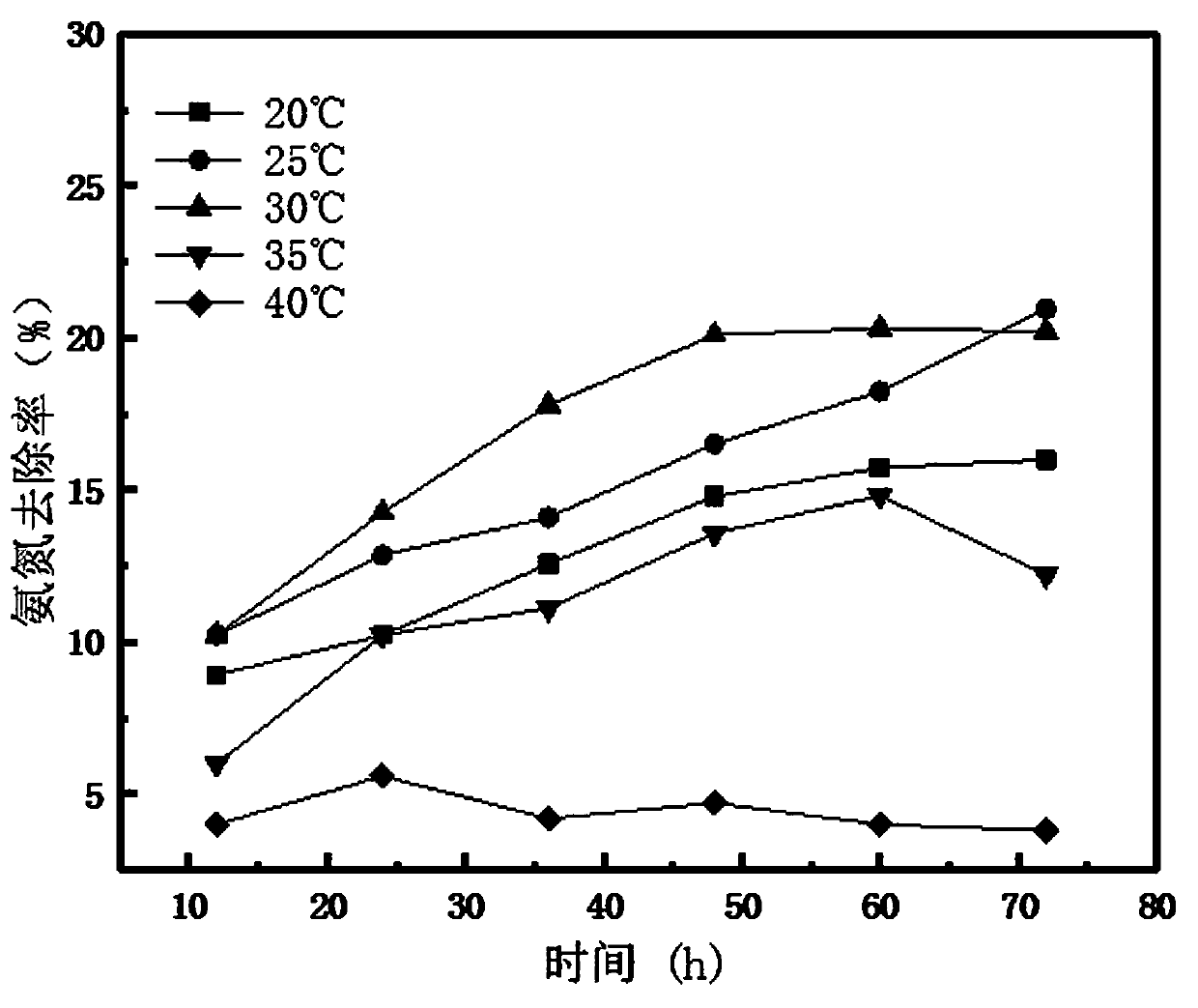

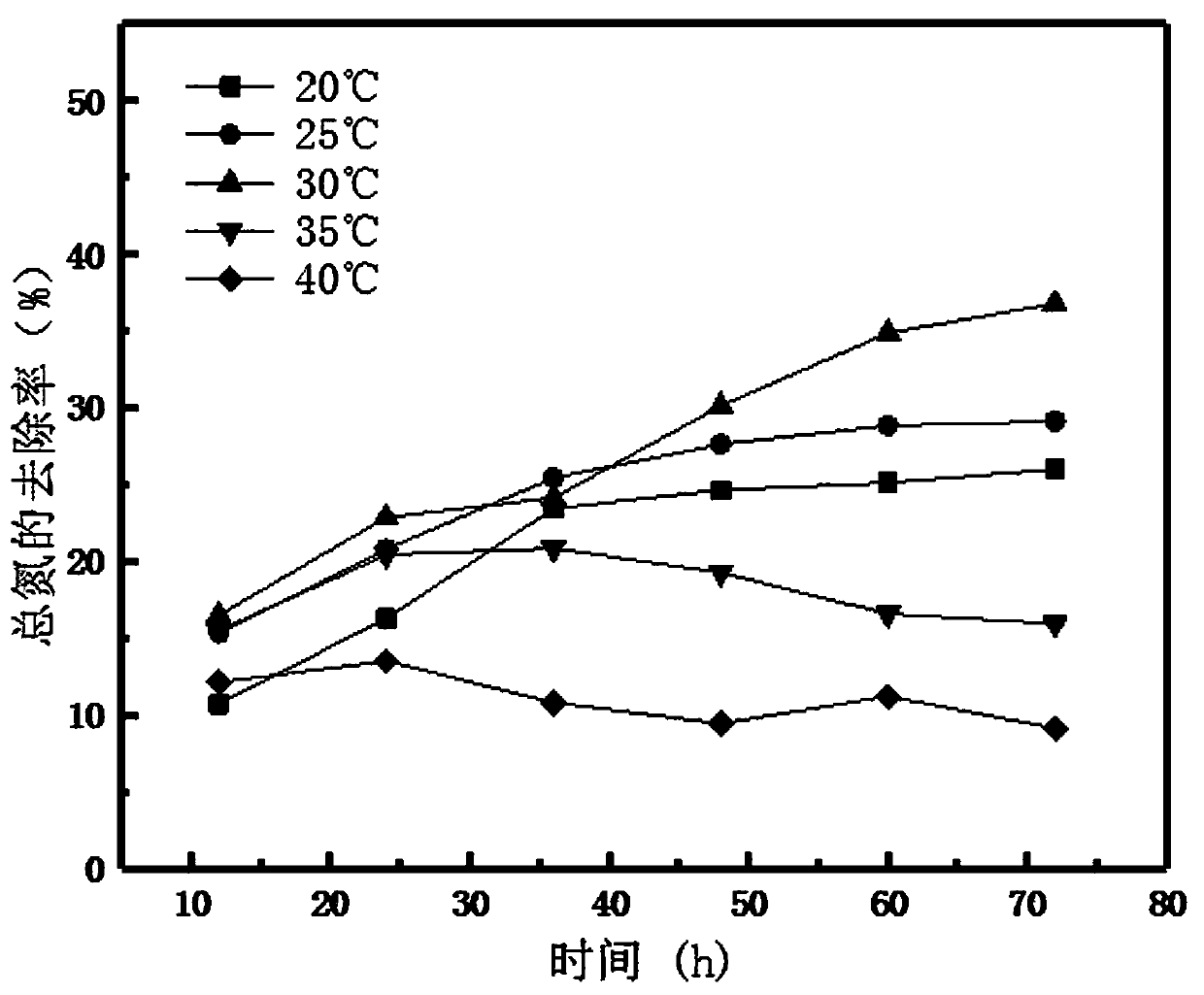

[0044] Only change the treatment temperature of step (3), and conduct parallel experiments at 25°C, 30°C, 35°C, and 40°C, the results are as follows Figure 1~3 shown.

[0045] Depend on figure 1 It can be seen that the overall trend of COD removal rate increases with the increase of temperature over time; in the first 40 hours, the changes at 25°C and 30°C basically increased from about 20% to about 30%, a...

Embodiment 3

[0050] (1) Adjust the abamectin fermentation wastewater to adjust the pH to 3;

[0051] (2) In the abamectin fermented waste water after step (1) treatment, drop Geotrichum candidum with 20% inoculation amount;

[0052] (3) Control the temperature at 25°C, the ventilation rate at 2.1L / min, and ferment for 72 hours;

[0053] (4) The avermectin fermentation wastewater treated in step (3) is subjected to solid-liquid separation, and the separated liquid phase is measured and calculated for COD removal rate, ammonia nitrogen removal rate, and total nitrogen removal rate.

[0054] Only change the pH of the abamectin fermentation wastewater in step (1), and carry out parallel experiments under the conditions of pH 4, 5, 6, and 7 respectively, and the results are as follows Figure 4~6 shown.

[0055] Depend on Figure 4 It can be seen that the removal rate of COD increases continuously with the rise of the pH value. The removal rate of COD at each pH in the first 25 hours increas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com