Sodium silicate alkali activated slag concrete recycling method

A technology of alkali excitation and concrete, which is applied in the direction of cement production, etc., can solve problems affecting coordinated development, aggravating urban land, resource shortages, etc., and achieves the effects of saving limestone resources, realizing reuse, significant economy and operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

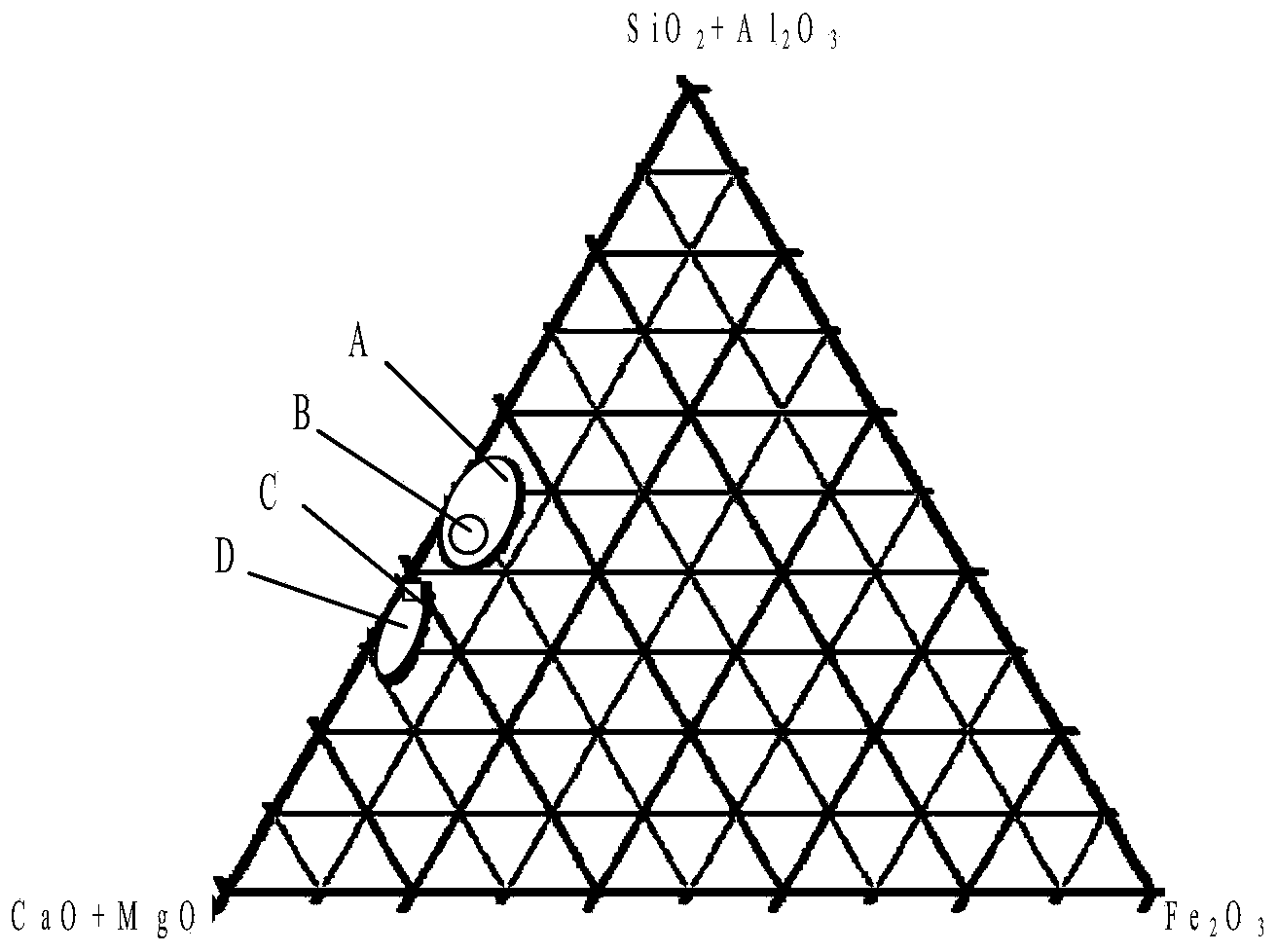

[0014] The sodium silicate alkali-activated slag concrete recycling method of the present invention first measures the chemical composition of sand (i.e. fine aggregate), stone (i.e. coarse aggregate) and slag used in the preparation of concrete. Under normal circumstances, its composition (mass percentage) index as follows:

[0015] Sand: 1-2% loss on ignition, 2-5% CaO, 60-80% SiO 2 , 10-15% Al 2 o 3 , 2-4% Fe 2 o 3 , 0-2% MgO, 1-6% R 2 O, and the balance of impurities;

[0016] Stone: 20-35% loss on ignition, 30-40% CaO, 10-20% SiO 2 , 1-3% Al 2 o 3 , 0-2% Fe 2 o 3 , 2-18% MgO, 0-1.5% R 2 O, and the balance of impurities;

[0017] Slag: 1-2% loss on ignition, 40-65% CaO, 15-25% SiO 2 , 1-5% Al 2 o 3 , 1-8% Fe 2 o 3 , 1-8% MgO, 0-2% R 2 O, and the balance of impurities.

[0018] In this embodiment, the specific selection pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com