Concrete gravel recycling and separating device

A separation device, concrete technology, applied in separation method, sedimentation separation, feeding/discharging device of sedimentation tank, etc., can solve the problems of consumption, manpower and material resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the drawings.

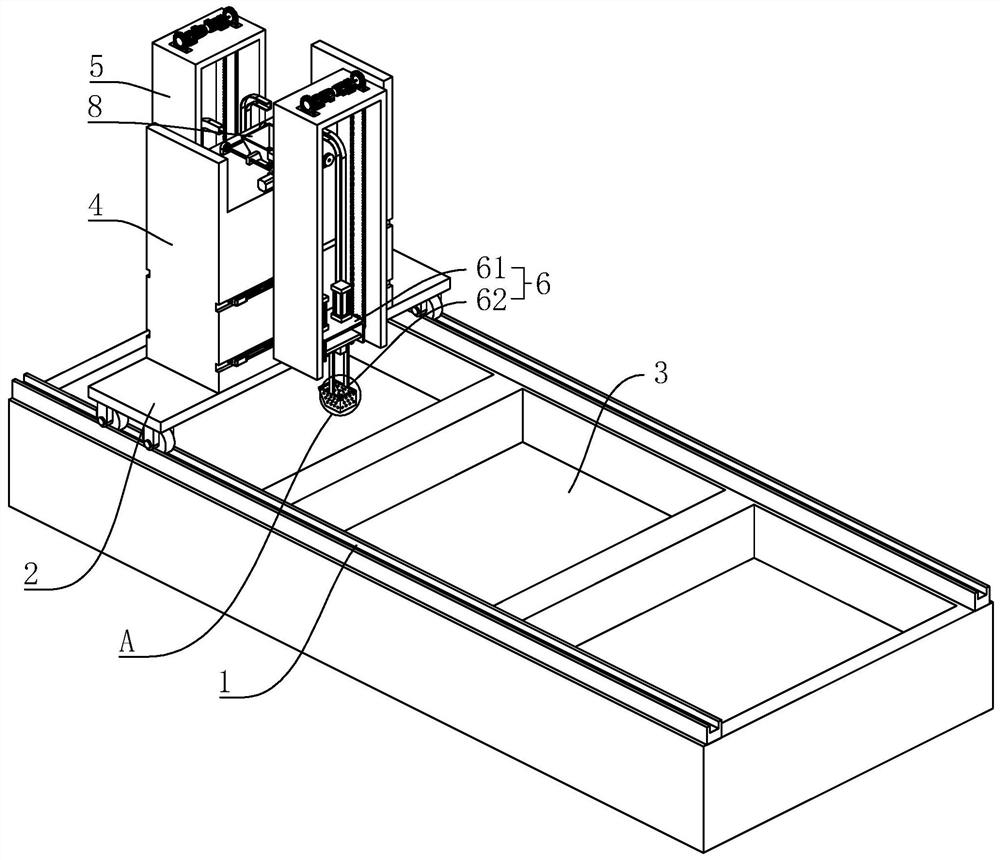

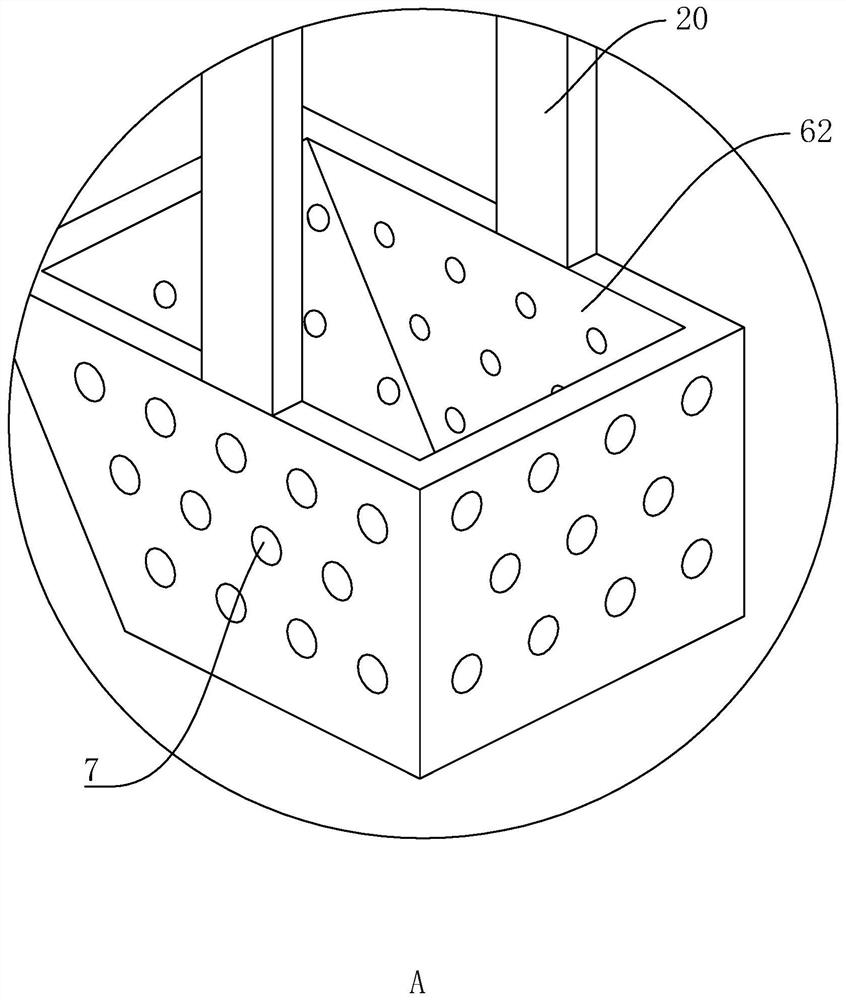

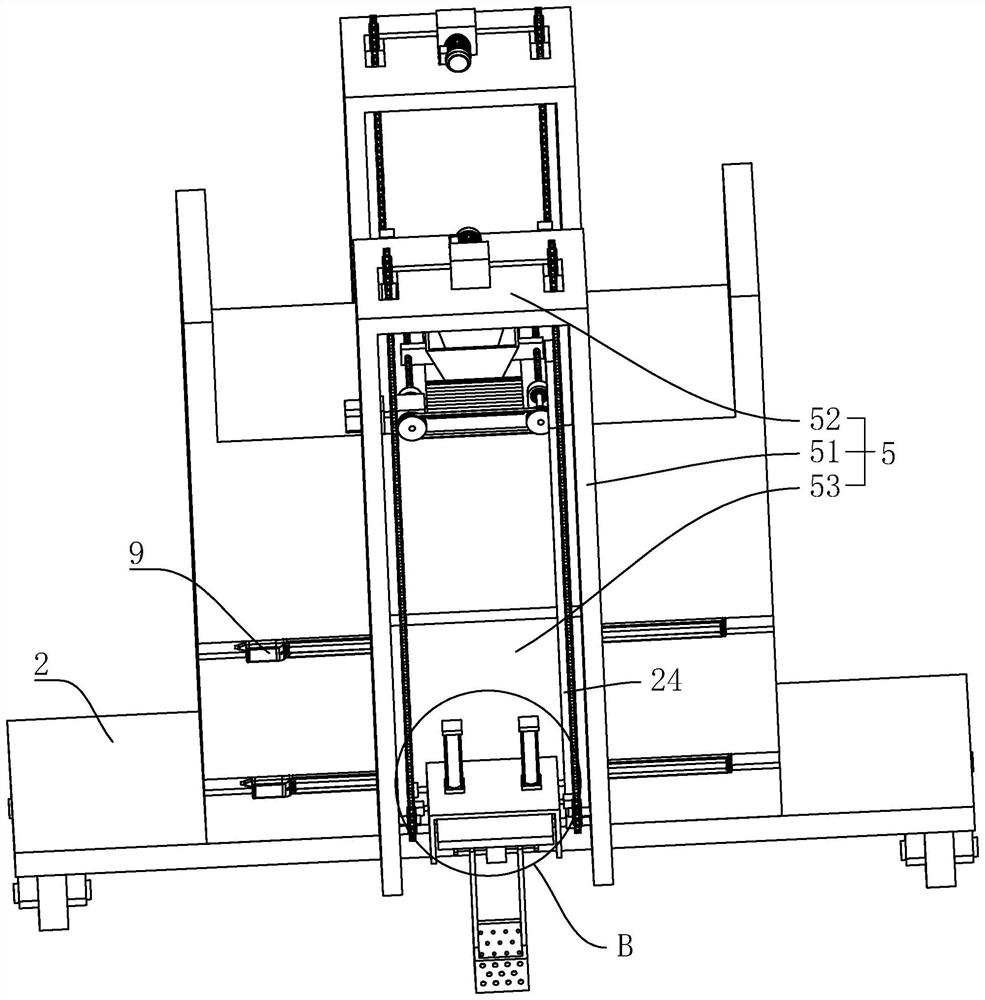

[0042] Reference figure 1 , Is a concrete sand and gravel recovery and separation device disclosed in the present invention, which includes two parallel moving rails 1 and a supporting plate 2 arranged between the two moving rails 1, and a plurality of edges are arranged between the two moving rails 1. The sedimentation tanks 3 are arranged in sequence in the horizontal direction, and the arrangement direction of the sedimentation tanks 3 is consistent with the length direction of the moving track 1. The upper end of the support plate 2 is fixedly connected to the organism 4. Both sides of the body 4 are horizontally slidingly connected with a support frame 5. Two sets of support frames 5 are arranged symmetrically about the center line of the width direction of the body 4, and the vertical sliding connection on the support frame 5 is useful Regarding the lifting mechanism 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com