High quality recycled aggregate recycling equipment for waste building concrete

A technology of waste concrete and recycled aggregate, which is applied in the field of building materials, can solve the problems of large performance gap of natural aggregate, many recycled aggregate cement mortars, and limited application range, so as to promote separation, prolong service life, and improve processing efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but it is not used as a basis for any limitation of the present invention.

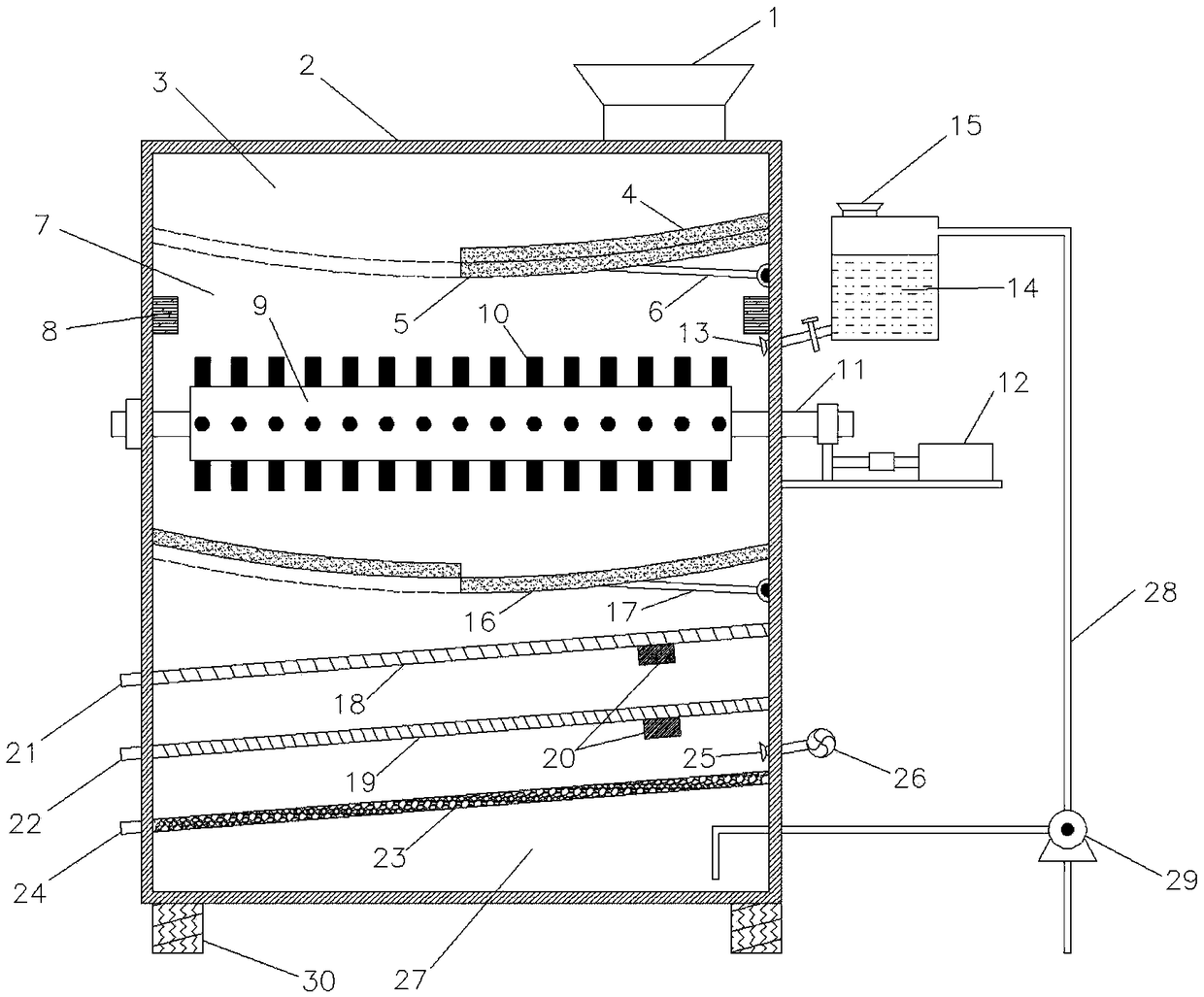

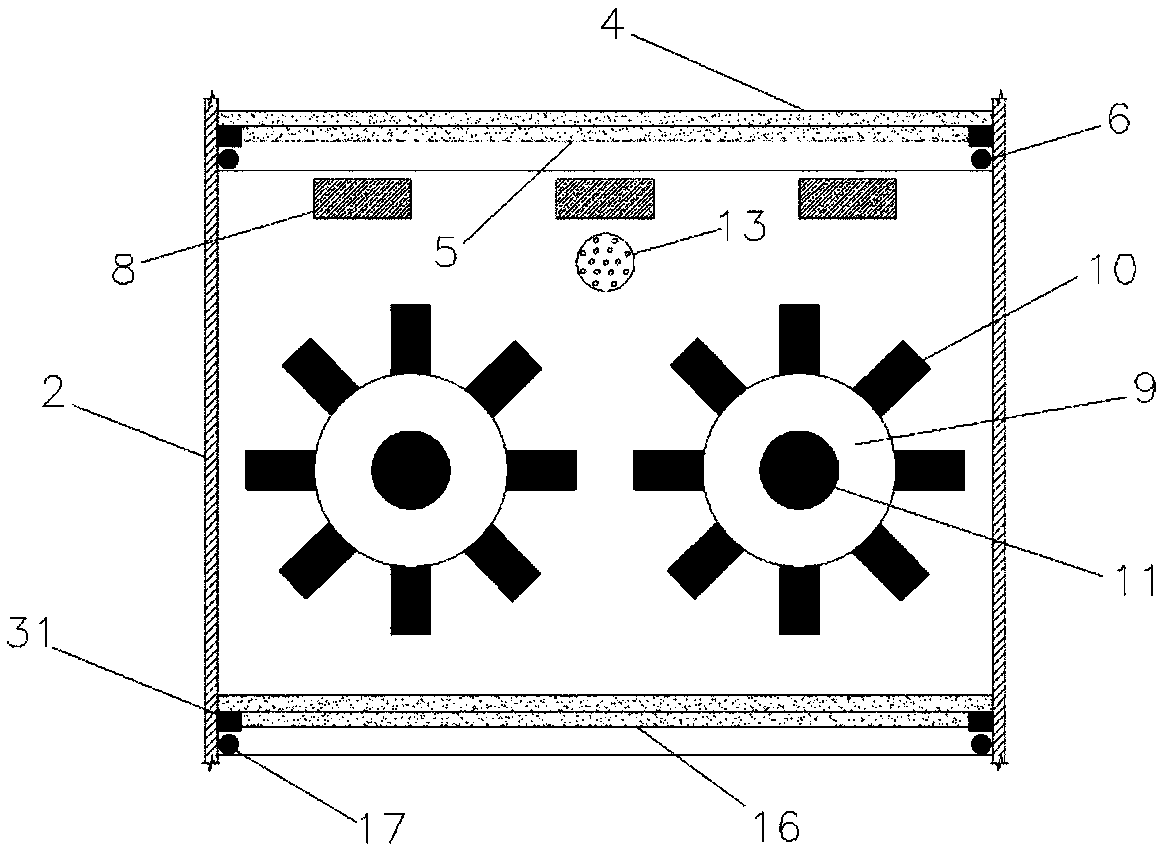

[0029] In a specific embodiment 1, such as figure 1 , figure 2 As shown, a high-quality recycled aggregate recovery equipment for waste concrete in buildings includes an equipment box 2, inside the equipment box 2 from top to bottom are a material storage chamber 3, a heating and stirring chamber 7, and a filtration and separation chamber. The top of the equipment box 2 is provided with a material inlet 1, and the bottom is provided with a shock-absorbing support 30, and the box is connected with a circulating water system.

[0030] Wherein, the storage cavity 3 is provided with a semi-arc fixed partition 4 fixed along the side wall of the equipment box 2 and a first sliding partition 5 below it corresponding to the feed inlet 1, and on the inner side wall of the equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com