Solid waste recycling device for concrete

A recovery device and concrete technology, applied in the direction of selling raw material supply devices, etc., can solve the problems of material waste, consumption of water and electricity resources and equipment resources, unfavorable environmental protection, etc., and achieve the effect of improving economic benefits, reducing consumption, and reducing material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

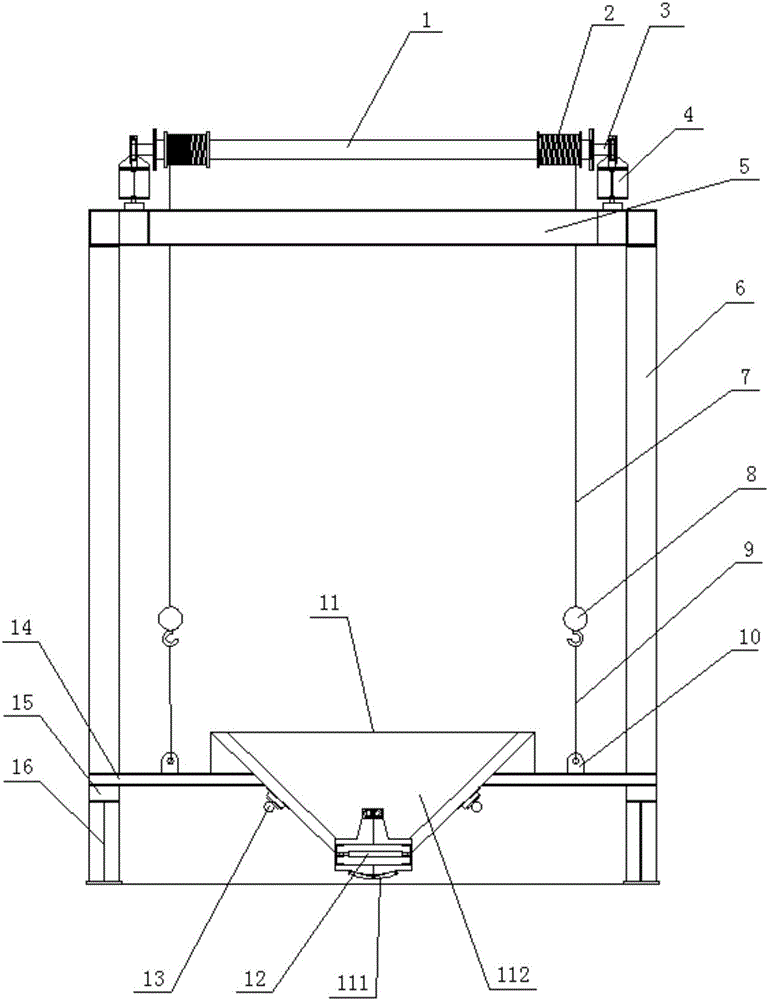

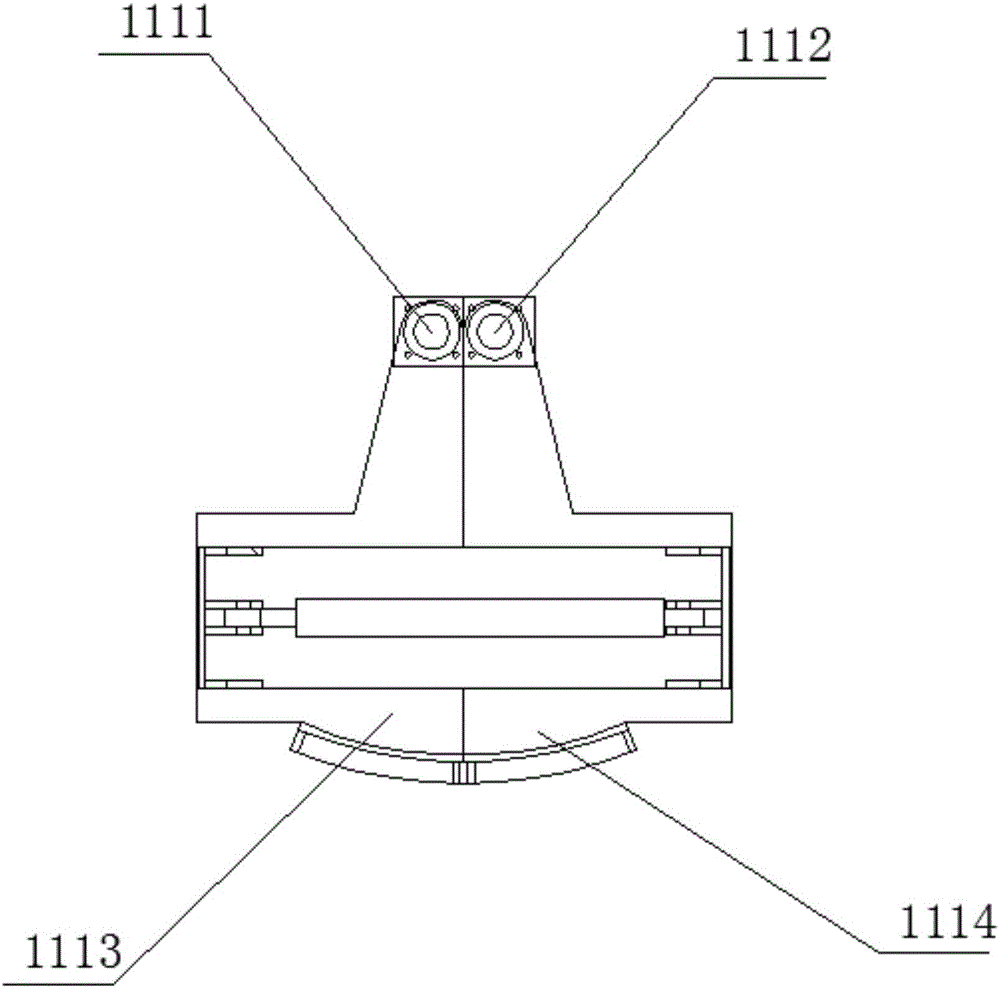

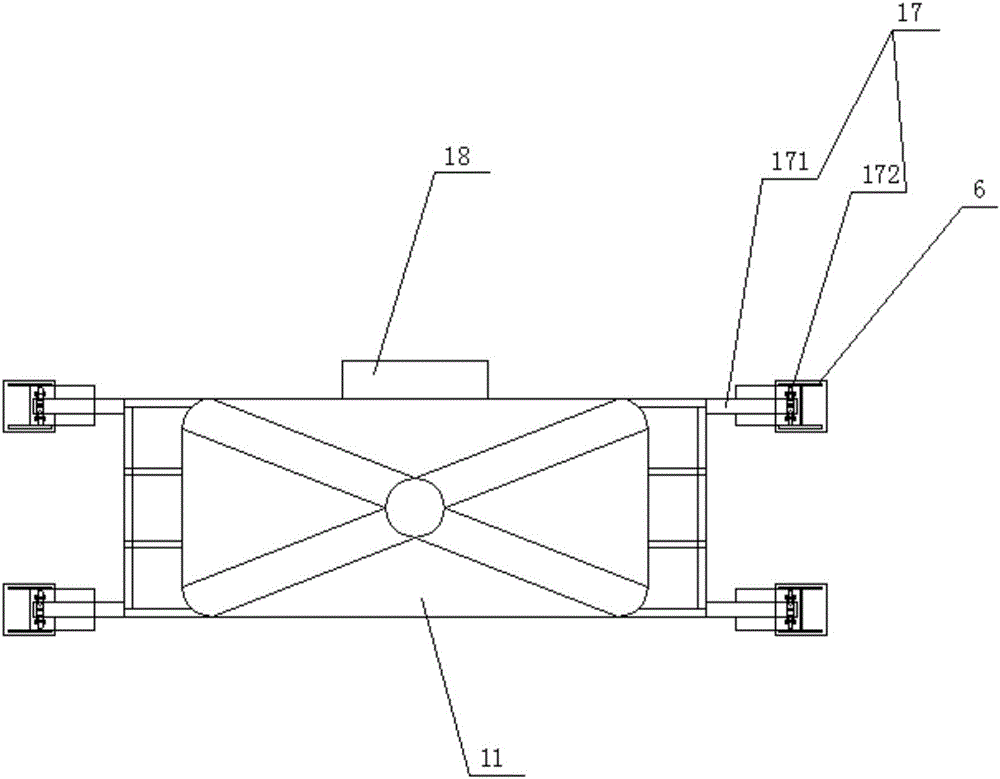

[0018] A solid waste recovery device for concrete, such as Figure 1-3 As shown, including column 6, column 6 is provided with upper frame 5, and upper frame 5 is provided with load cell 4, and load cell 4 weighs the material in the hopper 11 and obtains weight value; Load cell 4 A reel 1 is arranged on the load cell 4, a rolling shaft 3 is arranged on the load cell 4, and the rolling shaft 3 is arranged in the reel 1, and a wire groove 2 is arranged on the reel 1, and a first pull rope 7 is arranged on the wire groove 2, The first stay rope 7 is provided with a suspension hook 8, the suspension hook 8 is connected with the lower frame 14, the suspension hook 8 is provided with a second stay rope 9, the second stay rope 9 is provided with a positioning column 10, and the positioning column 10 is arranged on the lower frame. Frame 14 on. The lower frame 14 is provided with a hopper 11, the hopper 11 is provided with a vibration motor 13, the lower frame 14 is provided with a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com