Concrete recycling device

A technology of concrete and sedimentation tanks, which is applied in the direction of grain processing, etc., can solve problems such as improper waste gas treatment, daunting enterprises, difficulties in implementing reuse, etc., and achieves the effect of low cost and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

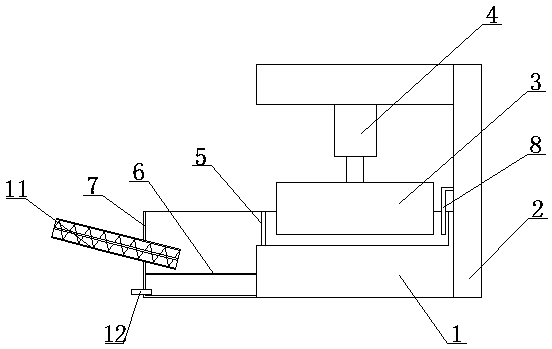

[0033] Such as Figure 1-Figure 4 As shown, in this embodiment, a concrete recycling device includes a base 1 for placing waste materials, a support 2 arranged on the base 1, a rolling board 3 located above the base 1, and a roller plate 3 arranged on the support 2 and driven The driving mechanism for the rolling plate 3 to move in the vertical direction; the base 1 is connected to the deposition tank 7; the deposition tank 7 is connected to the screw lifting mechanism 11.

[0034]Place construction solid waste such as abandoned concrete structures and discarded boards on the base 1, use the driving mechanism to drive the rolling plate 3 to move towards the base 1, and use the rolling plate 3 to exert pressure on the construction solid waste to break the construction solid waste , Structures such as wood boards and plastic boards are crushed under pressure and separated from their internal metal structures such as screws, and concrete structures are crushed under pressure and ...

Embodiment 2

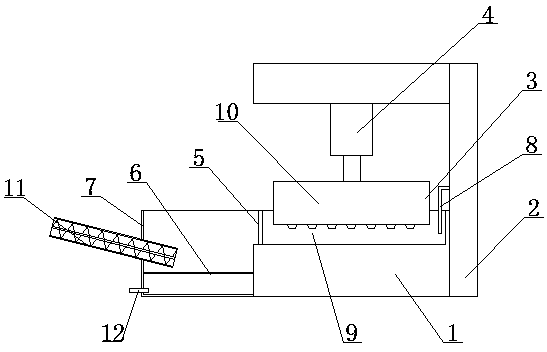

[0039] On the basis of the above embodiments, in this embodiment, the base 1 is provided with an isolation plate 5; the isolation plate 5 is provided with an opening communicating with the deposition pool 7; There is a water inlet pipe 8, and the water inlet pipe 8 is located on the side opposite to the opening. The isolation plate 5 can prevent the solid waste from splashing due to force during the pressurization process, thereby avoiding safety accidents, and can play a role in drainage, controlling the water flow to move toward the sedimentation tank to avoid liquid leakage. The water inlet pipe 8 is used to guide the water flow to the base 1, so that the solution is more convenient to use, helps to reduce labor intensity, and facilitates the realization of automatic control. The water inlet pipe 8 is provided with a pressure regulating valve to control the flow of water, so as to facilitate the control of the largest particle size of the solid debris that can be taken away...

Embodiment 3

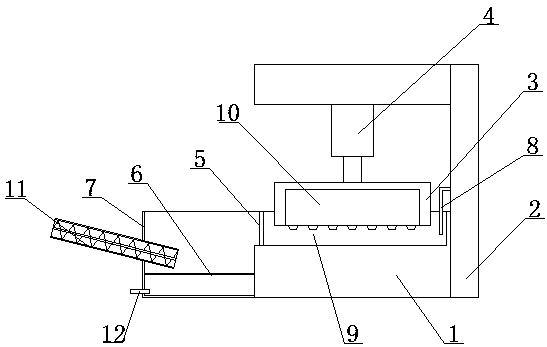

[0041] On the basis of the above embodiments, in this embodiment, a filter layer 6 located below the screw lifting mechanism 11 is arranged in the deposition tank 7 . The filter layer 6 can intercept the concrete fragments and only let the water flow through, so that the mud and the liquid are stratified, so as to avoid excessive moisture in the mud taken away by the screw lifting mechanism 11 . In this embodiment, other parts not described are the same as those in the foregoing embodiments, so details are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com