Mixed matrix membrane based on MXene/ZIF-composite material and preparation method

A technology of mixed matrix membranes and composite materials, applied in separation methods, chemical instruments and methods, membrane technology, etc., can solve the problems of limited application, difficulty in large-scale preparation, and high cost of inorganic membrane preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

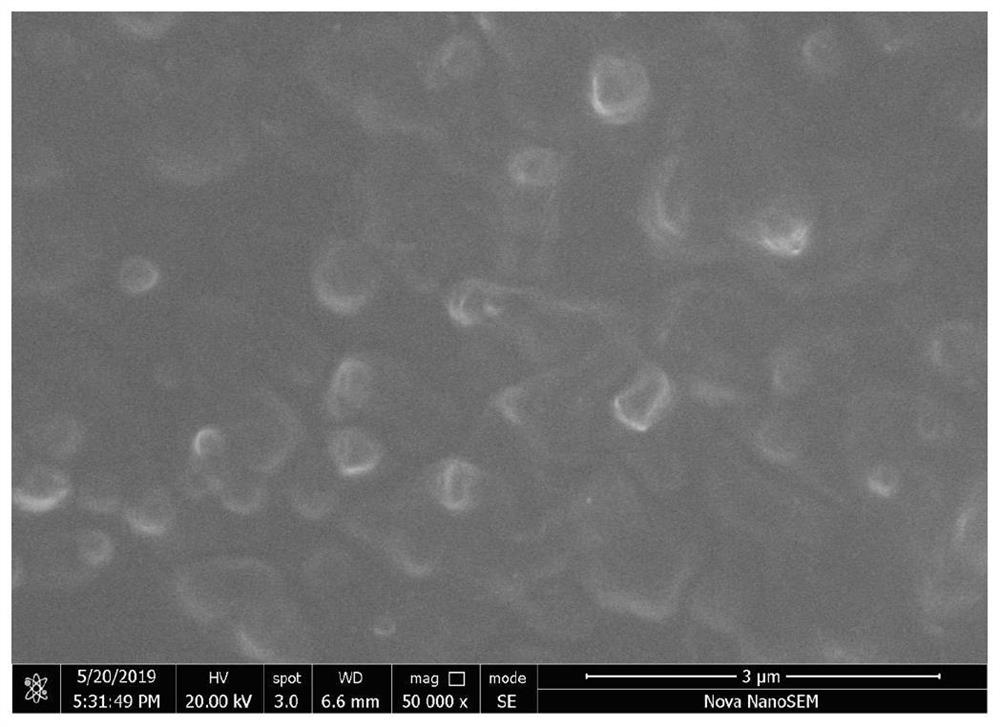

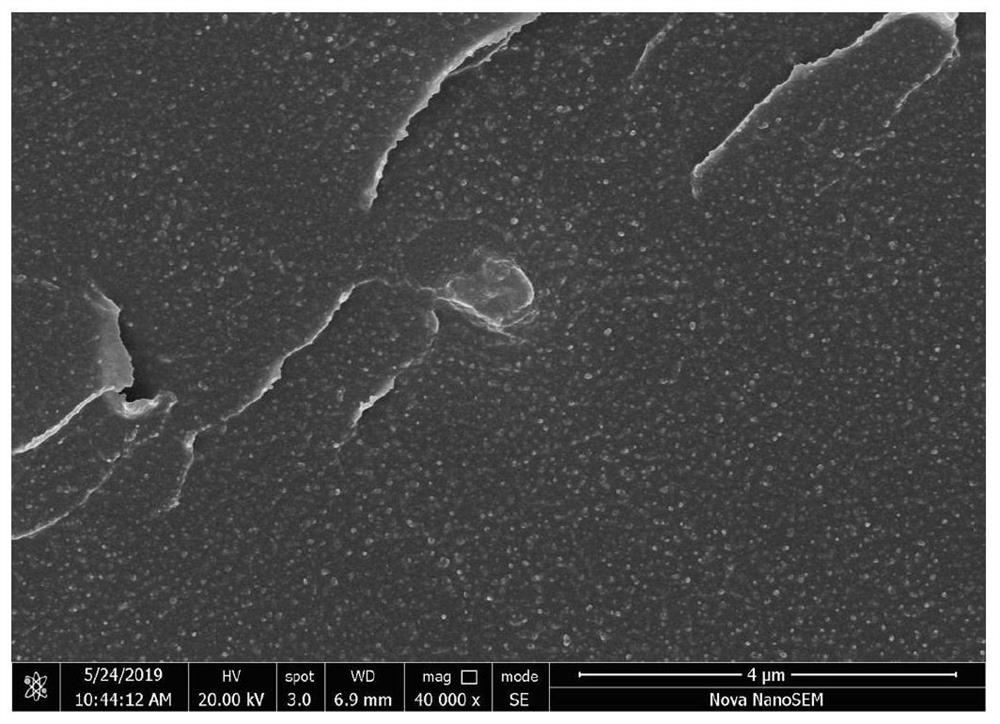

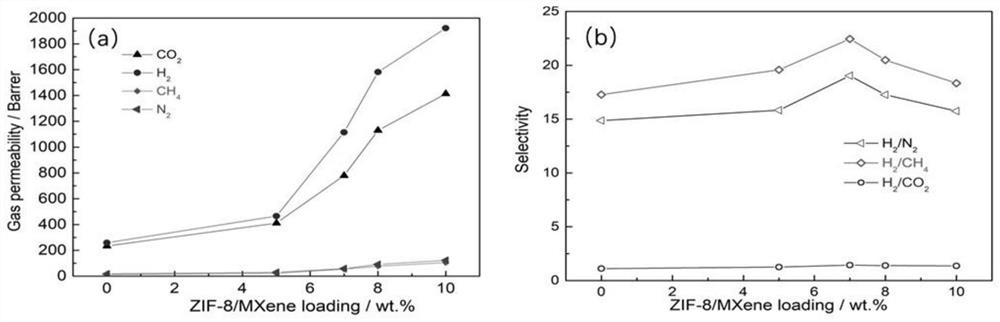

Image

Examples

Embodiment 1

[0034] A kind of mixed matrix film and preparation method based on MXene / ZIF-composite material, its scheme is:

[0035] Step 1. Preparation of MXene material: (1) Add 200 mesh MXene to the hydrofluoric acid solution, and add 7.5ml of 40wt% hydrofluoric acid per gram of MXene; heat to 40°C and stir for 6h, the stirring rate 100rpm;

[0036] (2) Centrifuge the solution obtained in (1) at a centrifugal rate of 5000 rpm, wash with deionized water and discard the supernatant. Repeat this step 4 times until pH=6;

[0037] (3) Freeze-dry the precipitate obtained in (2) for 24 hours to obtain a dry multilayer MXene material;

[0038] Step 2. Preparation of ZIF-8 material: (a) Mix zinc nitrate hexahydrate, 2-methylimidazole and methanol together, Zn 2+ : 2-methylimidazole: the mol ratio between methyl alcohol is 1:8:500; After mixing, seal the mouth of the cup with plastic wrap, stir 12 as for magnetic stirrer;

[0039](b) washing the precipitate obtained in (a) with N,N-dimethylfo...

Embodiment 2

[0052] A kind of mixed matrix film and preparation method based on MXene / ZIF-composite material, its scheme is:

[0053] Step 1. Preparation of MXene material: (1) Add 300 mesh MXene into the hydrofluoric acid solution, and add each gram of MXene into 14.6mL of 45wt% hydrofluoric acid; heat to 60°C and stir for 14h, the stirring rate 300rpm;

[0054] (2) Centrifuge the solution obtained in (1) at a centrifugal rate of 8000rpm, wash with deionized water and discard the supernatant. This step is repeated 6 times until pH=6.5;

[0055] (3) Freeze-dry the precipitate obtained in (2) for 36 hours to obtain a dry multilayer MXene material;

[0056] Step 2. Preparation of ZIF-8 material: (a) Mix zinc nitrate hexahydrate, 2-methylimidazole and methanol together, Zn 2+ : 2-methylimidazole: the molar ratio between methanol is 1:12:600; After mixing, seal the mouth of the cup with plastic wrap, and stir for 15h with a magnetic stirrer;

[0057] (b) washing the precipitate obtained in ...

Embodiment 3

[0070] A kind of mixed matrix film and preparation method based on MXene / ZIF-composite material, its scheme is:

[0071] Step 1. Preparation of MXene material: (1) Add 400 mesh MXene to the hydrofluoric acid solution, and add each gram of MXene to 20 mL of 50 wt% hydrofluoric acid; heat to 80°C and stir for 24 hours at a stirring rate of 500rpm;

[0072] (2) Centrifuge the solution obtained in (1) at a centrifugal rate of 10,000 rpm, wash with deionized water and discard the supernatant. This step is repeated 10 times until pH=7;

[0073] (3) Freeze-dry the precipitate obtained in (2) for 48 hours to obtain a dry multilayer MXene material;

[0074] Step 2. Preparation of ZIF-8 material: (a) Mix zinc nitrate hexahydrate, 2-methylimidazole and methanol together, Zn 2+ : 2-methylimidazole: the molar ratio between methanol is 1:16:700; After mixing, seal the mouth of the cup with plastic wrap, and stir for 18h with a magnetic stirrer;

[0075] (b) washing the precipitate obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com