Treatment method for separating copper and arsenic in arsenic filter cakes

A treatment method and arsenic separation technology, applied in the direction of improving process efficiency, can solve the problems of high cost, complex equipment and operating conditions, alkali consumption, etc., and achieve convenient operation, high separation rate of copper and arsenic, and simple production equipment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

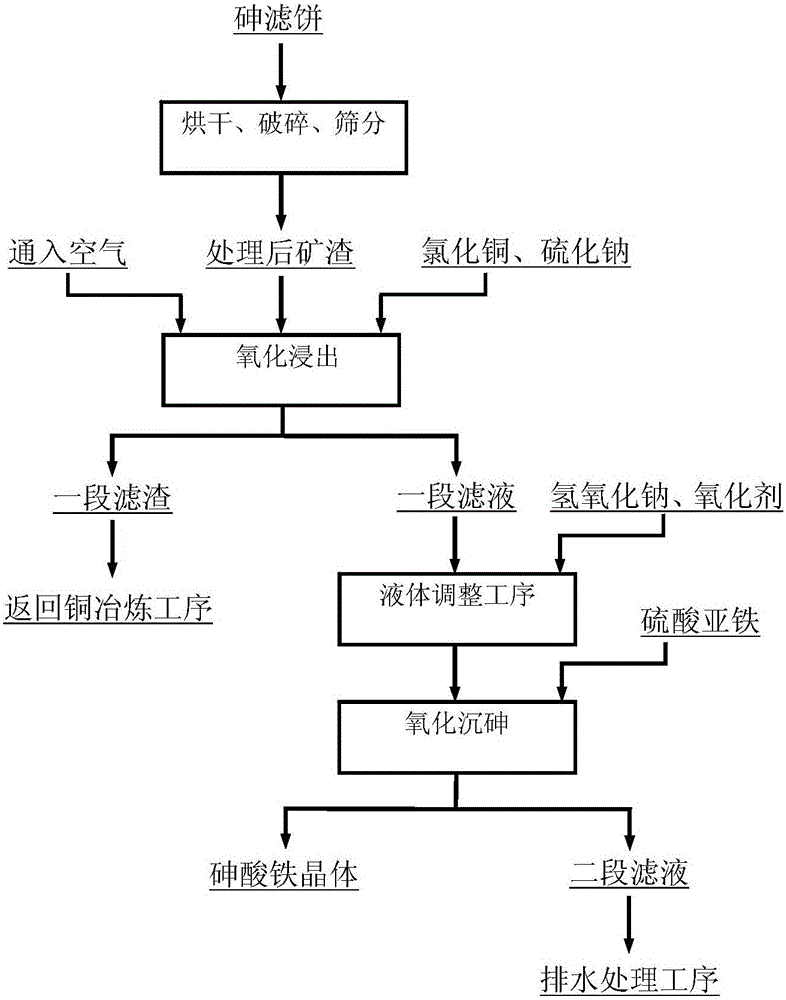

Method used

Image

Examples

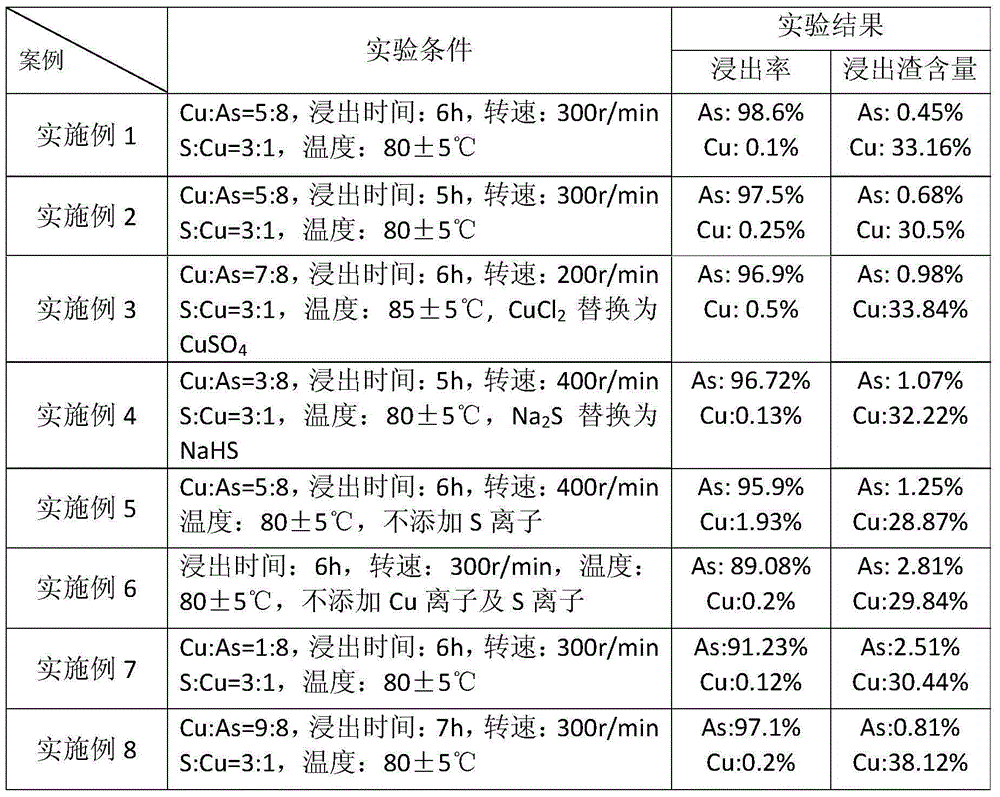

Embodiment 1

[0037] Embodiment 1: the copper arsenic separation treatment method of a kind of arsenic filter cake of the present invention, concrete operation is as follows:

[0038] The raw material used in embodiment 1 comes from a certain copper smelter. First, the raw material arsenic filter cake (the composition of the main element mass percentage included is: S42.10%, As18.20%, Cu17.10%, Bi0.82%, Pb0.41%, the main phase mass percentage components are: arsenic sulfide 1.2%, arsenate 0.75%, arsenic oxide 15.04%, soluble copper 7.23%, copper sulfide 8.94%) drying, grinding, After sieving, take 50g, add 500ml of water in proportion, mix well and then add CuCl according to Cu:As=5:8 2 Medicine 3g. The water bath heating controls the temperature at 80±5°C, while feeding air at 40L / min and stirring at a speed of 300r / min. After the reaction was carried out for 3 h, Na was added 2S solid 1.6g, continue heating and stirring for 3h. At the beginning of the leaching process, the solution wa...

Embodiment 2

[0041] Embodiment 2: the copper arsenic separation treatment method of a kind of arsenic filter cake of the present invention, specific operation is as follows:

[0042] The raw material used in embodiment 2 comes from a certain copper smelter. First, the raw material arsenic filter cake (the composition of the main element mass percentage included is: S31.2%, As13.5%, Cu17.60%, Bi0.72%, Pb0.23%, the main phase mass percentage components are: arsenic sulfide 0.95%, arsenate 0.55%, arsenic oxide 10.84%, soluble copper 8.51%, copper sulfide 9.57%) drying, grinding, Take 50g after sieving, add 600ml of water in proportion, mix well and then add CuCl according to Cu:As=5:8 2 Medicament 2.25g. The water bath heating controls the temperature at 80±5°C, while feeding air at 20L / min and stirring at a speed of 300r / min. After the reaction was carried out for 2 h, Na was added 2 S solid 0.88g, continue heating and stirring for 3h. At the beginning of the leaching process, the soluti...

Embodiment 3

[0045] Embodiment 3: the copper arsenic separation treatment method of a kind of arsenic filter cake of the present invention, specific operation is as follows:

[0046] The raw material used in embodiment 3 comes from a copper smelter, first the raw material arsenic filter cake (the composition of the main element mass percentage included is: S42.10%, As18.20%, Cu17.10%, Bi0.82%, Pb0.41%, the main phase mass percentage components are: arsenic sulfide 1.2%, arsenate 0.75%, arsenic oxide 15.04%, soluble copper 7.23%, copper sulfide 8.94%) drying, grinding, After sieving, take 50g, add 500ml of water in proportion, mix well and then add CuSO according to Cu:As=7:8 4 Medicament 4.2g. The water bath heating controls the temperature at 85±5°C and stirs at a speed of 200r / min. After the reaction was carried out for 1 h, Na was added 2 S solid 1.7g, continue heating and stirring for 5h. At the beginning of the leaching process, the solution was blue, and as the leaching process p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com