Carbon dot-molybdenum trioxide and carbon nitride composite catalyst, preparation method and applications thereof

A technology of molybdenum trioxide and carbon nitride, which is applied in the field of photocatalysis, can solve the problems of high recombination rate of photogenerated electrons and holes, low light utilization rate, etc., achieve high application prospects and use value, good material stability, meet The effect of mass production requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

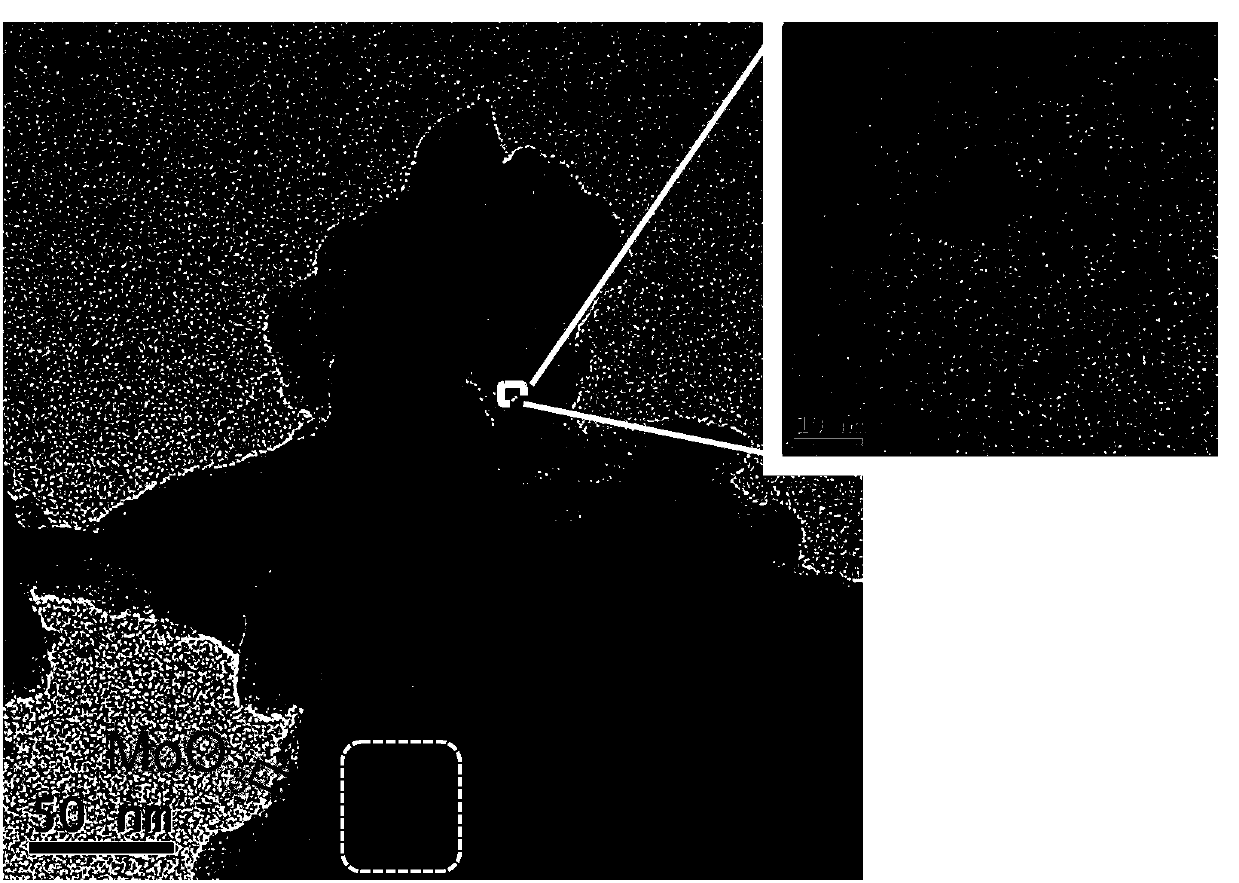

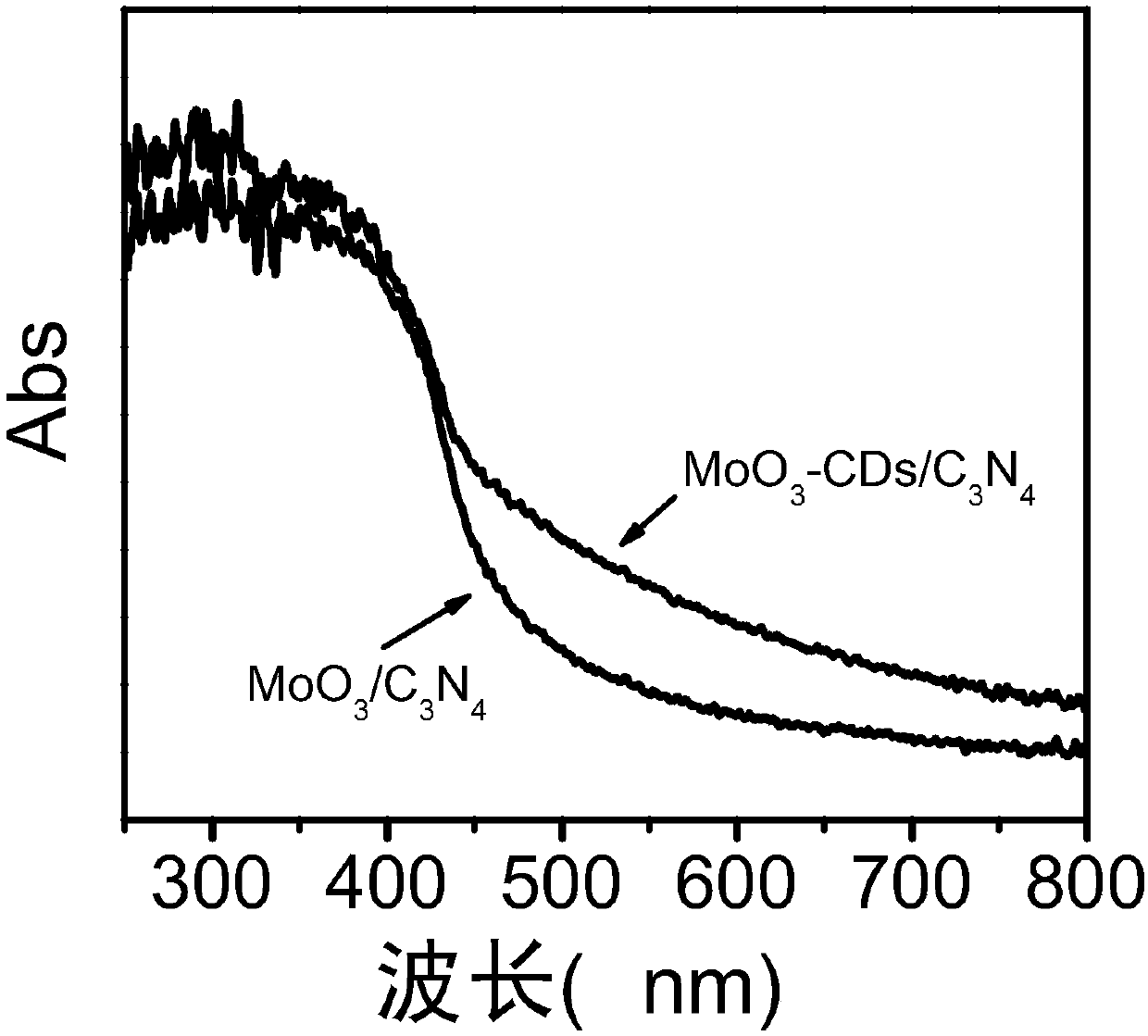

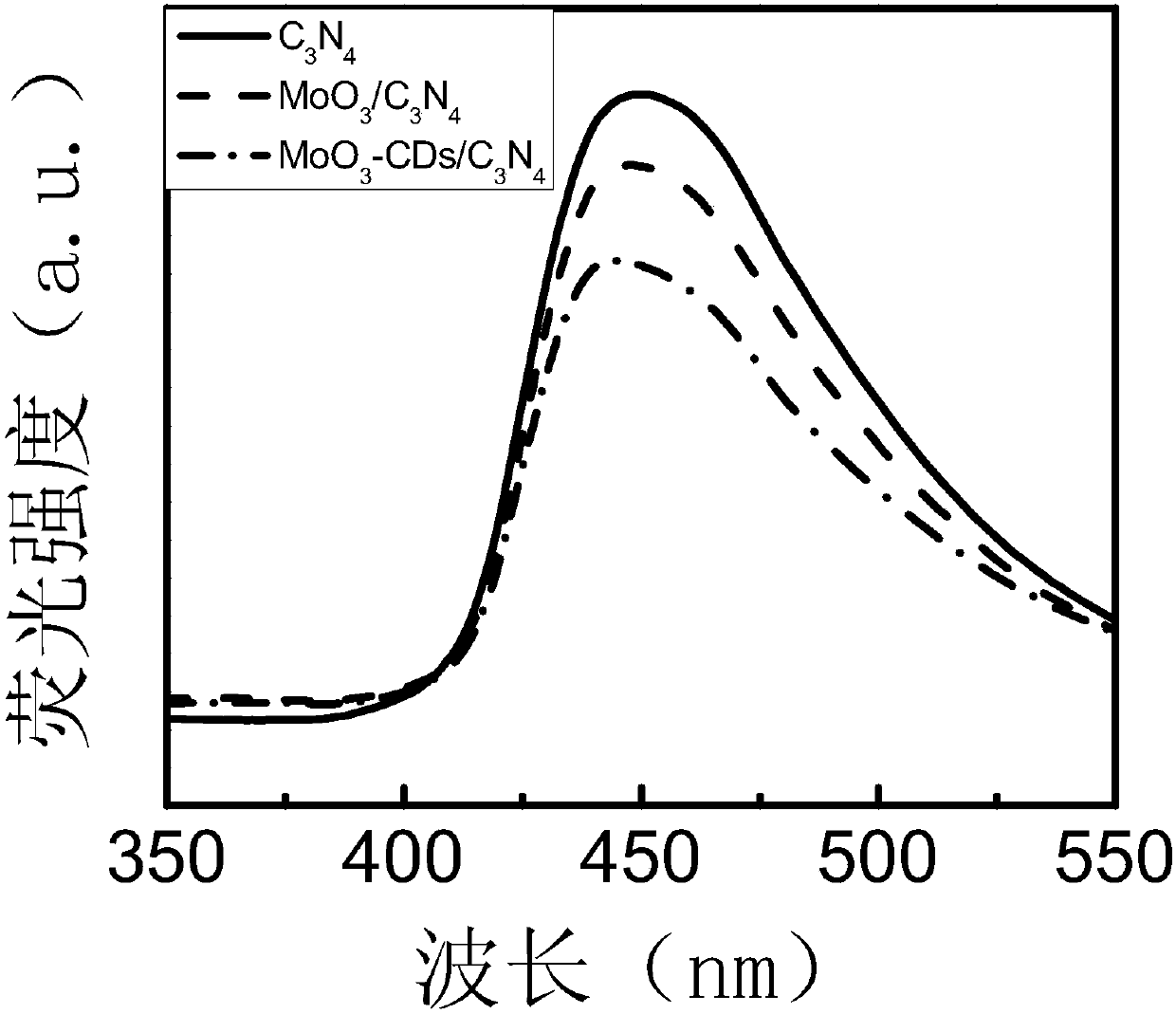

Image

Examples

Embodiment 1

[0033] A kind of preparation of carbon point and molybdenum trioxide composite carbon nitride photocatalyst, comprises the following steps:

[0034] (1) Weigh 3g of ammonium molybdate heptahydrate and place it in an alumina crucible, heat it at 80°C for 12h, then transfer it to a muffle furnace, raise the temperature to 450°C at a rate of 2.5°C / min and keep the temperature for reaction 5h; after cooling to room temperature, grind for 30min and sieve to obtain off-white MoO 3 powder;

[0035](2) Weigh 1g of urea and 3g of citric acid in a 50ml beaker, add 10ml of ultrapure water, ultrasonically dissolve it for 10min, then transfer it to a polytetrafluoroethylene high-temperature hydrothermal reactor, and react at 180°C for 5h; wait for it to cool to room temperature, a brown aqueous solution was obtained, and the solution was centrifuged to remove large particles, dried and ground to obtain a brown-black CDs powder;

[0036] (3) Weigh 3g of dicyandiamide and place it in an al...

Embodiment 2

[0047] A kind of preparation of carbon point and molybdenum trioxide composite carbon nitride photocatalyst, comprises the following steps:

[0048] (1) Weigh 5g of ammonium molybdate heptahydrate and place it in an alumina crucible, bake it at 90°C for 10h, then move it to a muffle furnace, raise the temperature to 550°C at a rate of 4°C / min and maintain the temperature React for 6 hours; after cooling to room temperature, grind for 30 minutes and sieve to obtain pale MoO 3 powder;

[0049] (2) Weigh 1.5g of urea and 3.3g of citric acid into a 50mL beaker, add 15mL of ultrapure water, ultrasonically dissolve for 10min, transfer to a polytetrafluoroethylene high-temperature hydrothermal reactor, and react at 160°C for 3.5h; After it was cooled to room temperature, a brown aqueous solution was obtained, and the solution was centrifuged to remove large particles, dried and ground to obtain a brown-black CDs powder;

[0050] (3) Weigh 5 g of dicyandiamide and place it in an alu...

Embodiment 3

[0053] An application of carbon dots of the present invention and molybdenum trioxide composite carbon nitride photocatalyst to degrade antibiotics, comprising the following steps:

[0054] (1) Weigh 30 mg of the photocatalyst MoO prepared in Implementation 1 3 -CDs / C 3 N 4 Place in a quartz photolysis tube, add a tetracycline solution with a concentration of 20mg / L and a volume of 50mL, ultrasonically disperse for 5 minutes, and then place it in a photolysis instrument for stirring and adsorption for 30 minutes.

[0055] (2) light source adopts 350W xenon lamp configuration 420nm optical filter to carry out photocatalytic reaction, and the reaction time is 90min, treats to react with liquid chromatography detection solution remaining tetracycline concentration (C t ). According to the formula P=(C 0 -C t )*100% to calculate the removal rate of tetracycline, where C 0 is the initial concentration of tetracycline. The result is as Figure 4 shown.

[0056] (3) take by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com