Lobe separation equipment and method

A technology for separating equipment and slivers, applied in glass manufacturing equipment, optics, instruments, etc., can solve the problems of panel pollution, water residue on glass surface, difficult position control, etc., to achieve the effect of easy separation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The split separation equipment and method proposed by the present invention are described in detail as follows in conjunction with the accompanying drawings and embodiments.

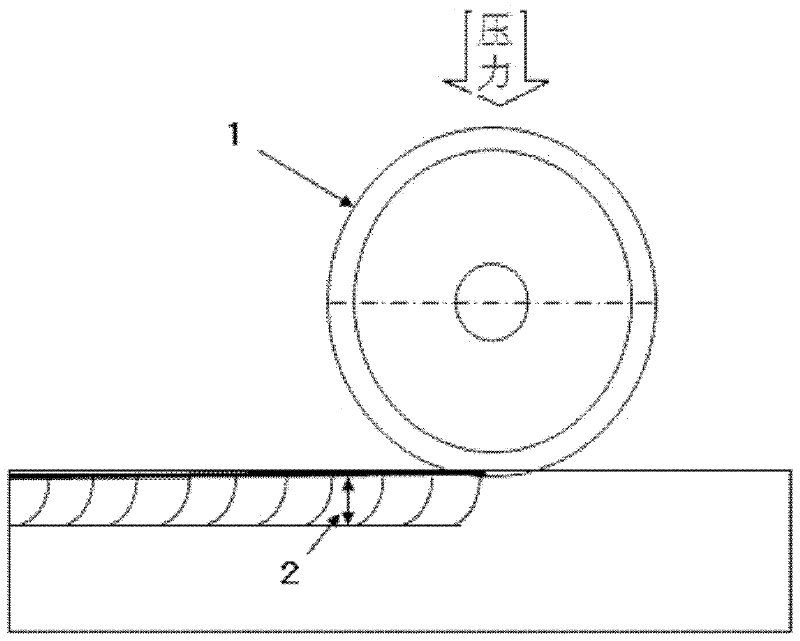

[0022] According to the principle of vibration, the equipment and method of the present invention make the cutting cracks on the glass substrate formed with cutting cracks fully extend in the thickness direction of the glass substrate, so as to achieve the effect of splitting the lobes.

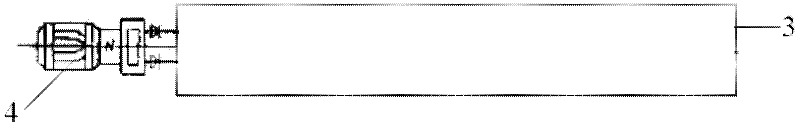

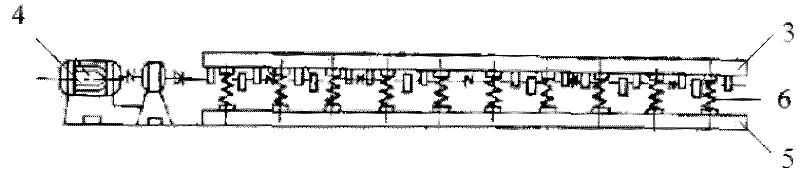

[0023] Such as figure 2 As shown, the splitting device according to an embodiment of the present invention includes: a vibration platform 3, which is used to fix at least one liquid crystal panel to be split, and drives the liquid crystal panel to vibrate, so that the cutting cracks on the glass substrate of the liquid crystal panel Fully extended during the vibration, the glass substrate fractures along the cutting crack, thereby achieving sliver separation.

[0024] The device in this embodiment further inclu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com