Zip fastener

A technology of zipper tape and warp yarn, which is applied in the field of zipper tape, which can solve the problems that the zipper vertical strips cannot be corrected to a linear state, the vertical direction of the zipper is uneven, and the weaving structure does not have stretch, so as to achieve a good appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

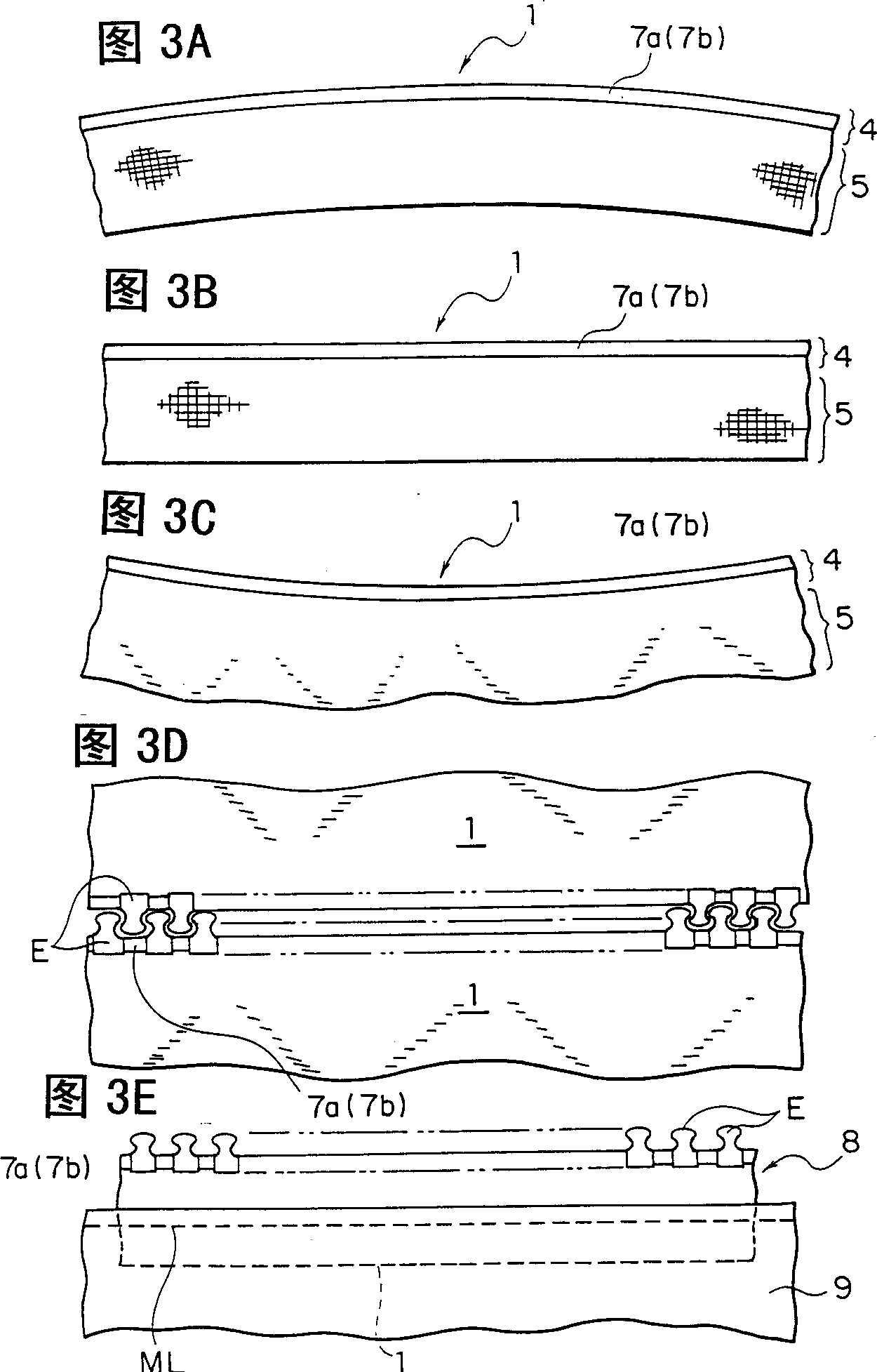

[0024] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings.

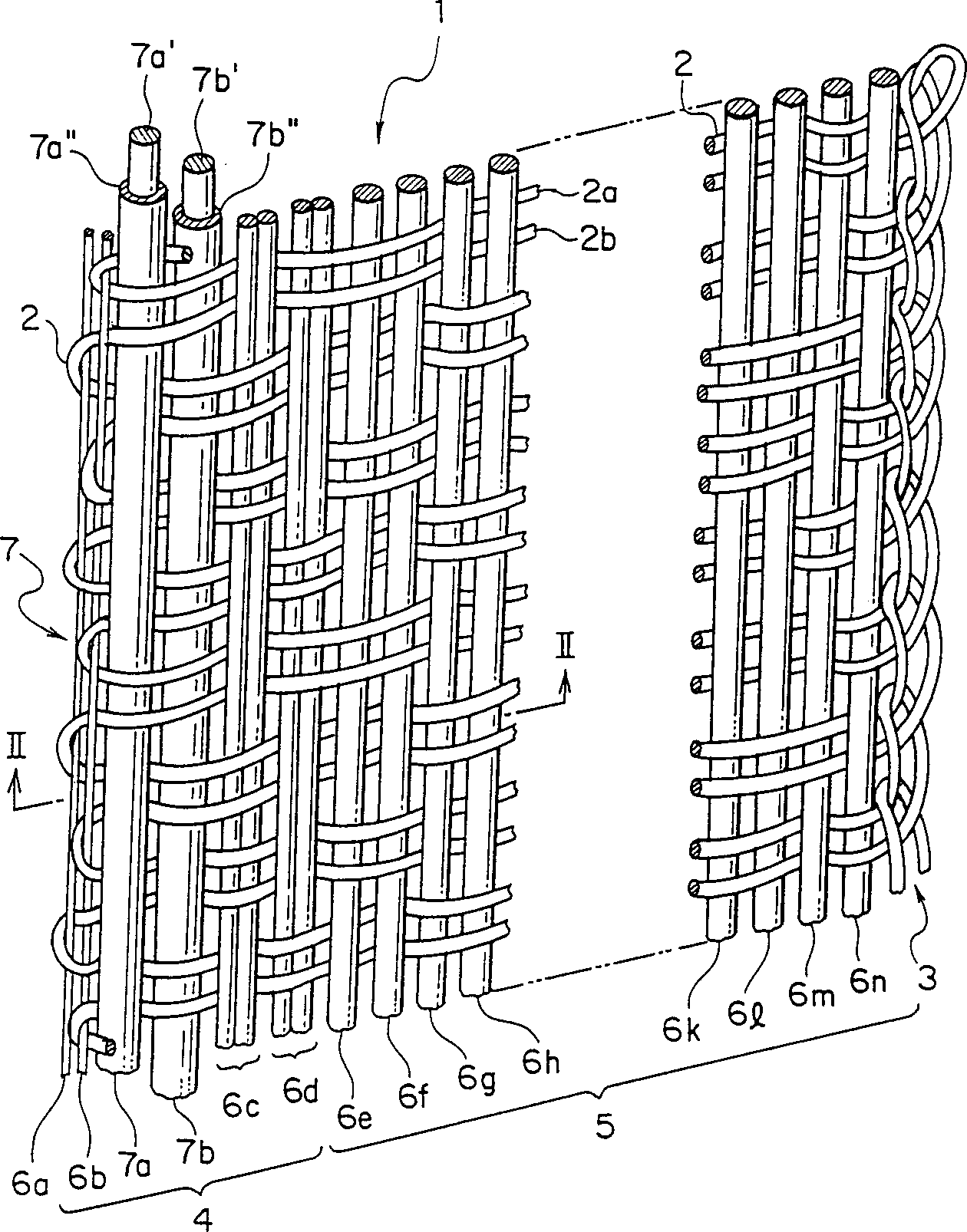

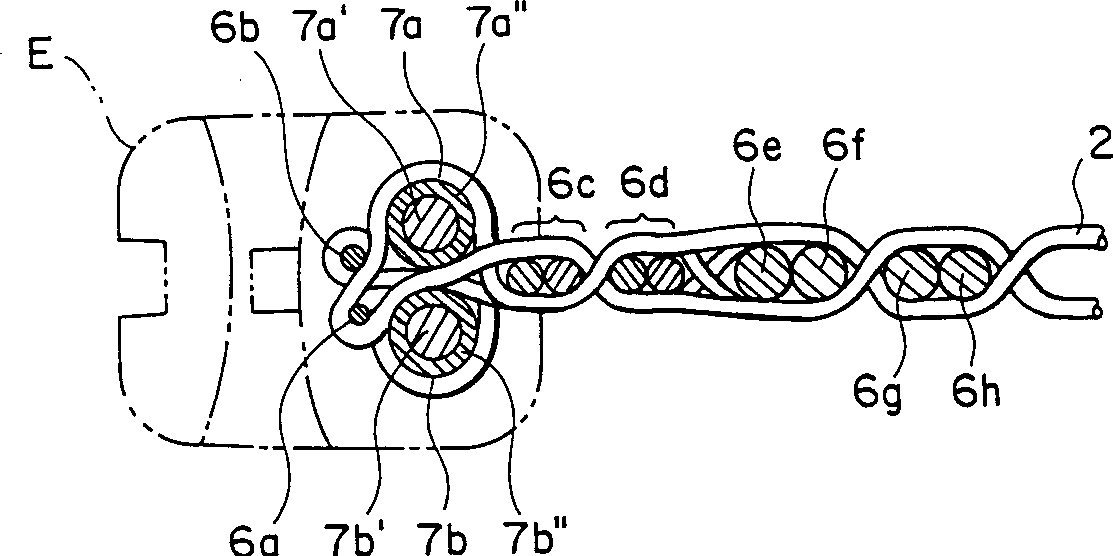

[0025] figure 1 The weaving structure of the fastener tape which is a typical example of the basic structure of this invention is shown. Simultaneously, figure 1 The braided structure shown is only roughly represented for the sake of understanding, in fact, as figure 2 As shown, it is a dense structure.

[0026] Usually, such woven zipper tapes are woven by a narrow weaving machine, which is called a knitting machine. Thus, the individual threads are reciprocated in the gap so that two parallel threads are inserted into a single weft thread 2 . Although in this figure, the two inserted yarns 2a, 2b constituting the weft yarn 2 are separated from each other in the vertical direction, actually, they are in close contact with each other in the vertical direction. Then, the loop end formed at the return end of the weft yarn 2 is wound with the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com