Circuit board splitting machine

A technology of circuit board and board splitting machine, which is applied in the direction of metal processing machinery parts, feeding devices, and attachments of shearing machines, etc. It can solve problems such as broken parts, rough incisions, and cracked solder joints, so as to prevent solder joints from cracking , Reduce stress and prevent parts from breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

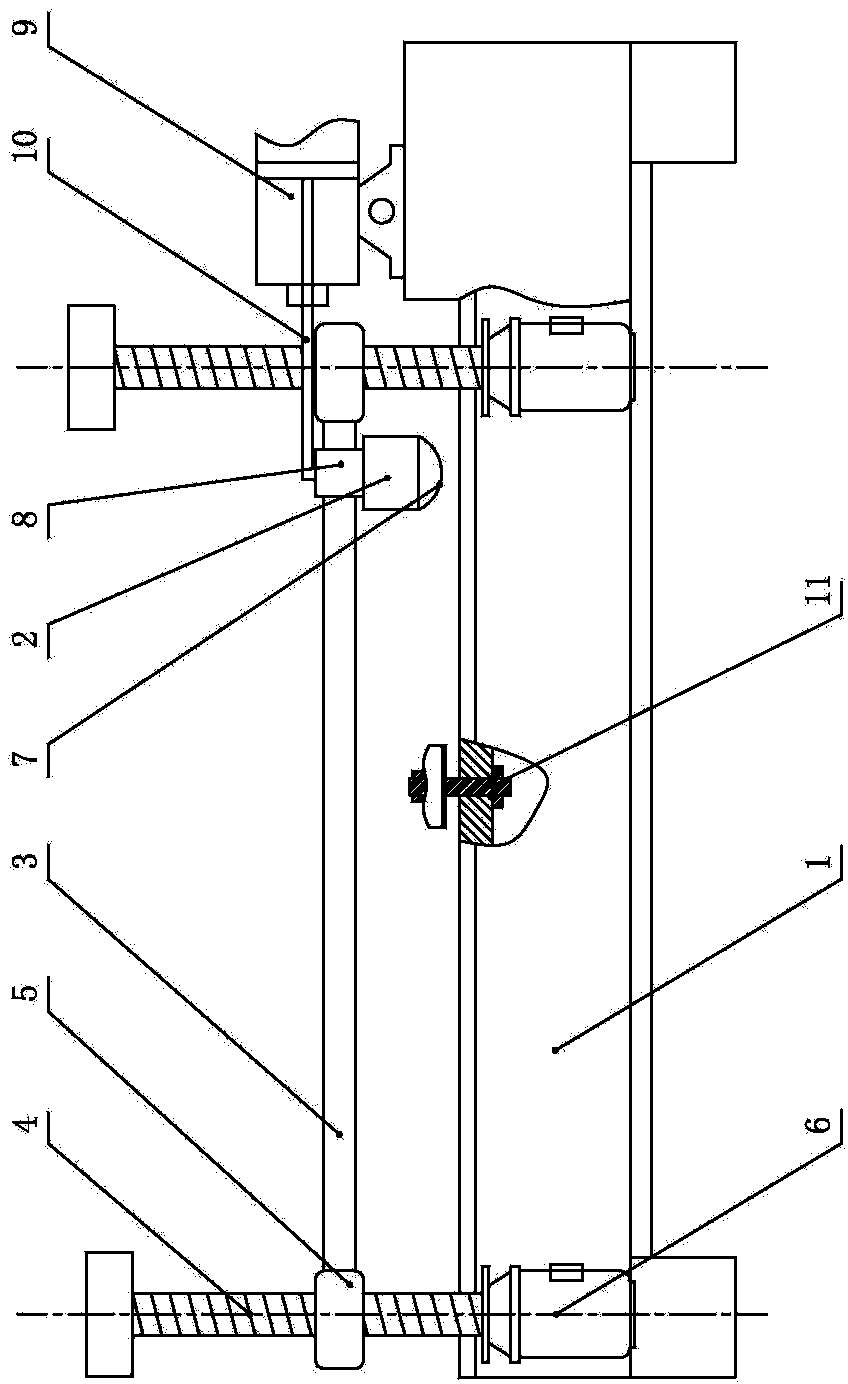

[0014] Such as figure 1 As shown, a circuit board splitting machine includes a cutting table 1 , a tool holder 2 and a guide rail 3 . The guide rail 3 is fixed on the cutting table 1 through a liftable support. The liftable support includes a screw 4 arranged on the left and right sides of the cutting table 1 and a nut seat 5 connected to the two ends of the guide rail 3. The nut seat 5 and the lead screw 4 are connected by threads. , the lower end of leading screw 4 is provided with respective driving motor 6, and driving motor 6 starts and drives leading screw 4 to rotate, thus drives nut seat 5 to run up and down, realizes the lifting of guide rail 3, and then realizes the lifting of blade 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com