Cutting device for cutting a thin and adhesive belt, in particular a cord belt

A technology of cutting equipment and cord belts, applied in the field of cutting equipment, can solve the problems of complicated design of a pressing device, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

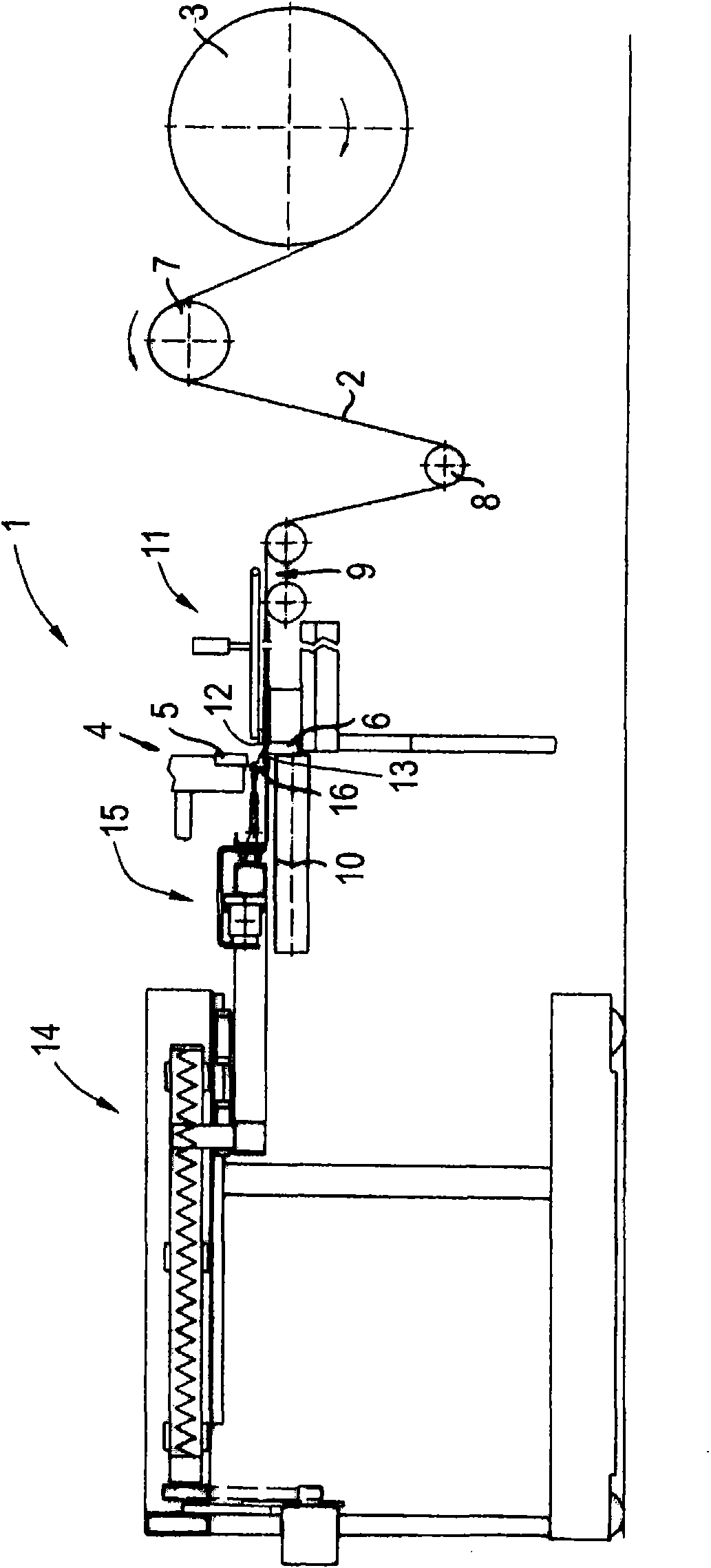

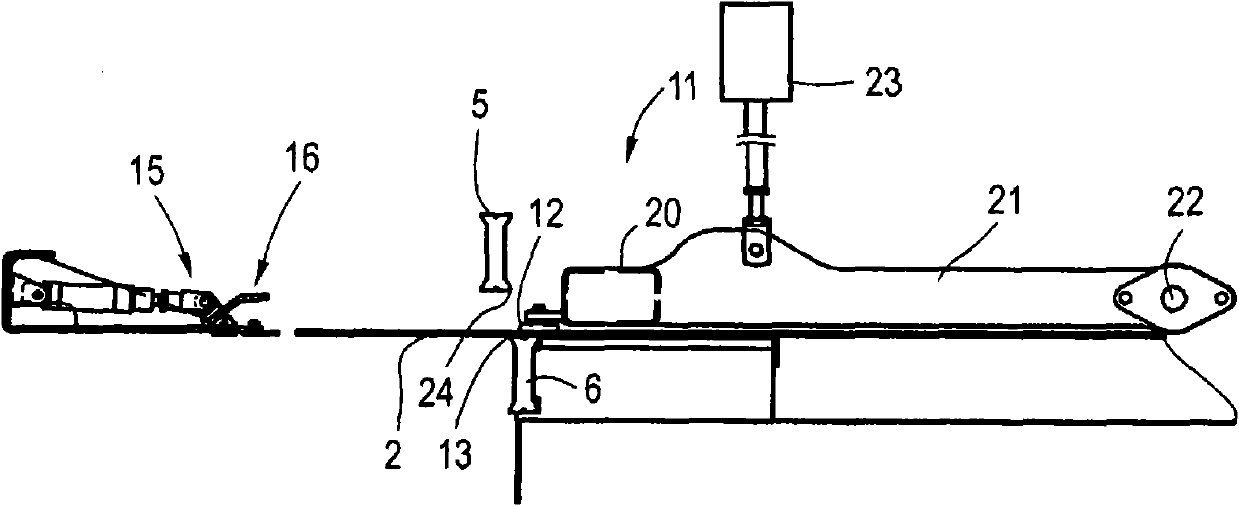

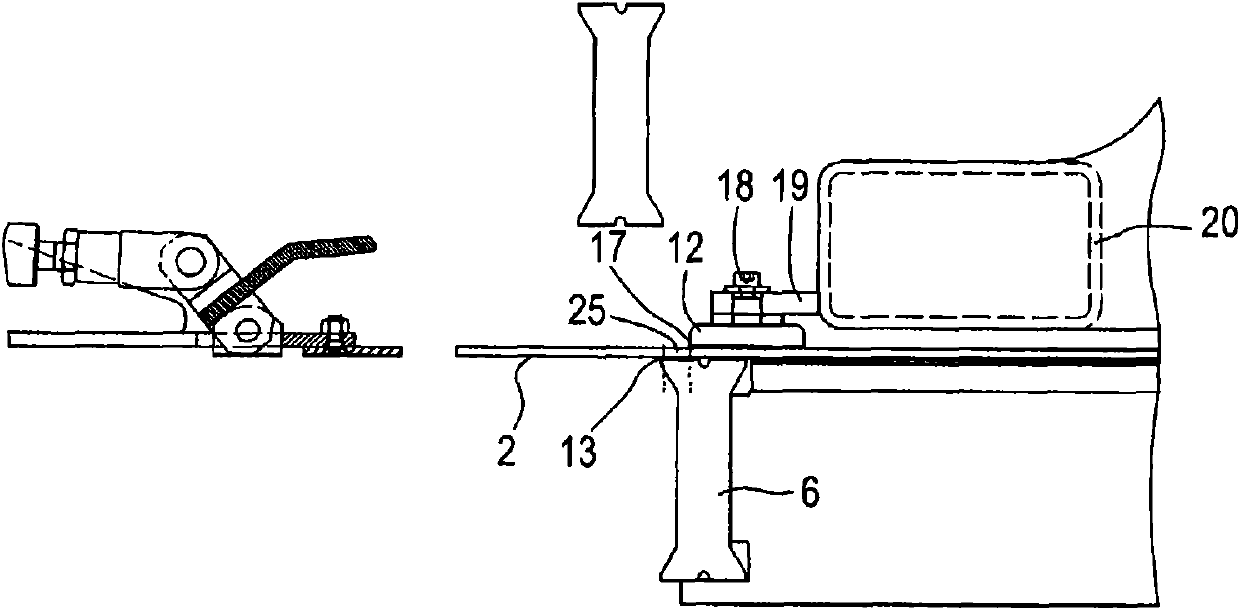

[0025] figure 1 A cutting device 1 according to the invention is shown with which a cord strip 2 drawn from a supply roll 3 can be cut. The cutting device 1 comprises a cutting device 4 comprising a vertically movable upper knife 5 and a stationary lower knife 6 . The cord strip 2 is guided via guide wheels / rollers 7 , 8 to the cutting device 1 where it is fed to an incoming conveyor belt 9 . Depending on the cutting angle with respect to the longitudinal direction of the cord strip 2 , the incoming conveyor belt 9 can be swung around a vertical axis from the vertical orientation of its longitudinal axis to the cutting edges of the lower knife 6 and the upper knife 5 accordingly. The cut cord lengths are transported via a delivery conveyor 10 to a downstream processing unit, for example a joining device.

[0026] In order to fix the position of the cord strip 2 to be cut in the area of the cutting edge, a hold-down device 11 is provided, which comprises a magnetic slat 12,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com