Polytetrafluoroethylene millipore membrane for purifying PM2.5

A polytetrafluoroethylene and microporous membrane technology, which is applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve problems such as uneven distribution, large pore size, and inability to filter dust, and achieve uniform membrane thickness, Uniform fiber thickness to avoid inconsistent filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

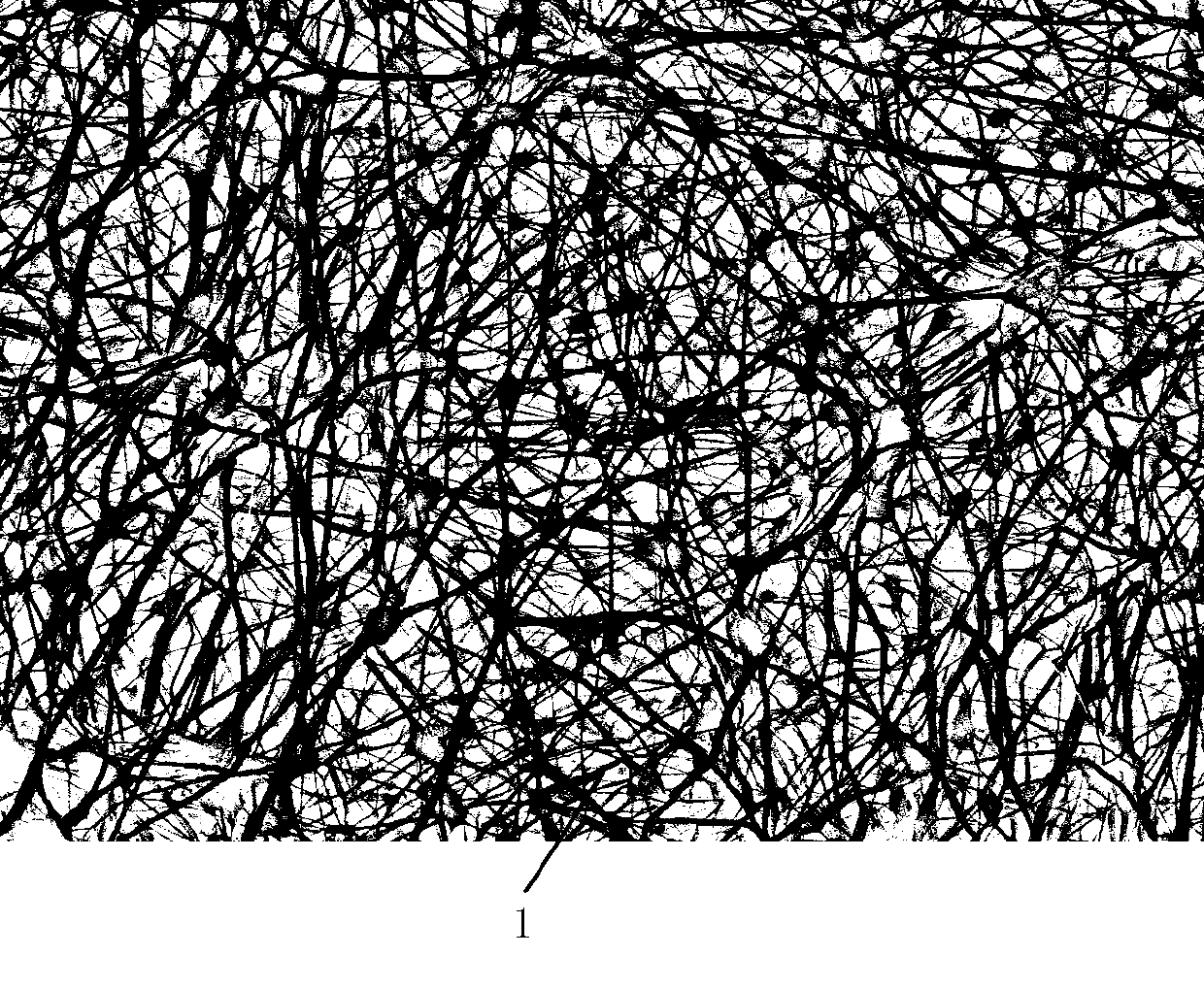

[0027] A polytetrafluoroethylene microporous membrane for purifying PM2.5 of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0028] Referring to Fig. 1, a polytetrafluoroethylene microporous membrane for purifying PM2.5 according to the invention includes a polytetrafluoroethylene microporous membrane 1.

[0029] The polytetrafluoroethylene microporous membrane 1 is formed by fibers in a three-dimensional cross-shaped structure.

[0030] The thickness of the polytetrafluoroethylene microporous membrane 1 formed by fibers with a three-dimensional cross-shaped structure is 5-8 μm, and the thickness tolerance is ±1.5 μm.

[0031] The polytetrafluoroethylene microporous membrane 1 formed of fibers with a three-dimensional cross-shaped structure has a pore diameter of 0.2 μm-0.5 μm and a porosity of 80%-90%.

[0032] The strength of the polytetrafluoroethylene microporous membrane 1 formed by fibers in a three-dimens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com