Preparation method of complex-shaped large cemented carbide wear-resistant block

A technology of cemented carbide and complex shapes, applied in the field of powder metallurgy cemented carbide, which can solve the problems of inconsistent compact density, difficult manufacturing, and large material waste, and achieve uniform density distribution, uniform density, and wear resistance high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

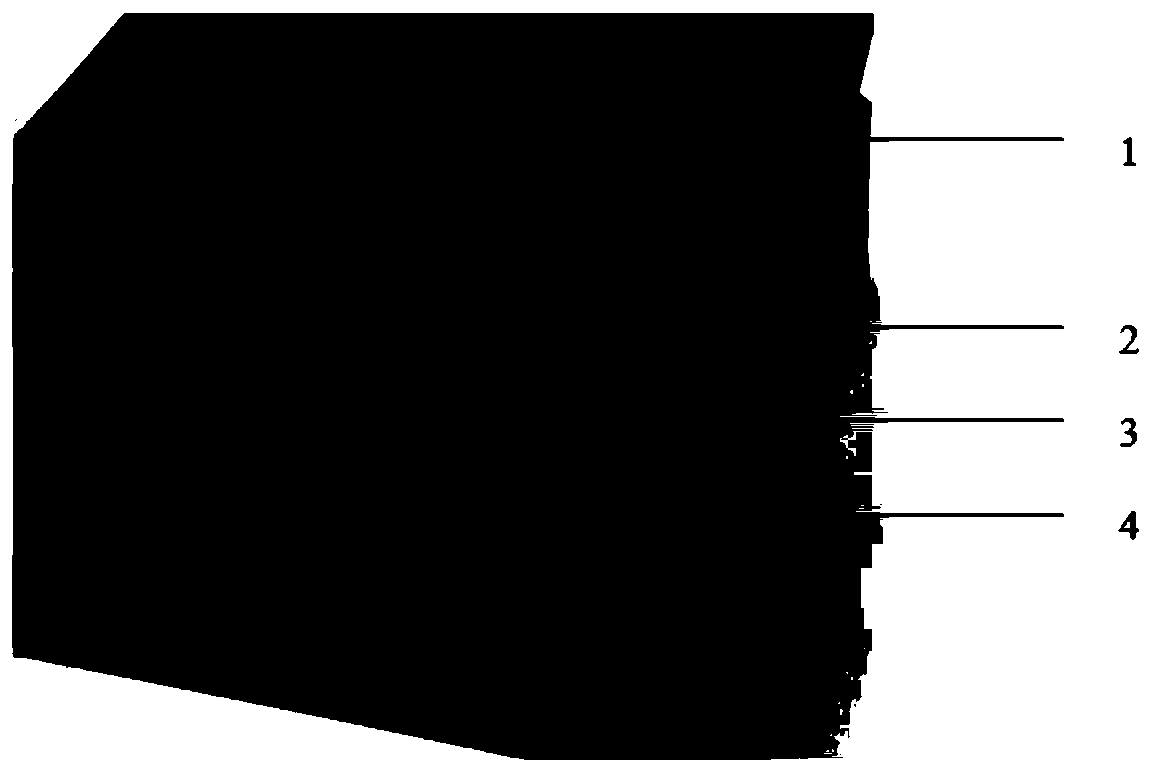

[0037] Put the cemented carbide mixture (including molding agent) with a cobalt content of 8wt% into a steel mold, use a 500-ton hydraulic press, hold the pressure for 300 seconds under a pressing pressure of 75MPa, and press-form a 280mm×260mm×148mm pre- After wrapping the preform with latex film, hold the pressure in a cold isostatic press for 8 minutes under a pressure of 180MPa, perform the first cold isostatic pressing, take out the compact after pressure relief, and cut it out with a diamond wire saw figure 1 platform 4 in , CNC milled out figure 1 Chamfer 1, assembly groove 2 and excessive stress relief arc 3, and then grind to correct the size, and then carry out the second cold isostatic pressing with the latex film bag, and the final pressure of the second cold isostatic pressing is 120MPa , after unloading, pressure sintering is carried out, the sintering pressure is 6MPa, and the final sintering temperature is 1410°C, and then a large-scale hard alloy wear-resistan...

Embodiment 2

[0039] Put the cemented carbide mixture (including molding agent) with a cobalt content of 10wt% into a steel mold, use a 315-ton hydraulic press, hold the pressure at 55MPa for 400 seconds, and press to form a 280mm×260mm×148mm preform , after wrapping the preform with a latex film, hold the pressure in a cold isostatic press for 10 minutes under a pressure of 185MPa, perform the first cold isostatic pressing, take out the compact after the pressure is released, and cut it out with a diamond wire saw figure 1 platform 4 in , CNC milled out figure 1 The chamfer 1, the assembly groove 2 and the excessive stress relief arc 3 are ground, and then the size is corrected by grinding, and then the second cold isostatic pressing is carried out with the latex film bag, and the final pressure of the second cold isostatic pressing is 110MPa. After unloading, pressure sintering is carried out, the sintering pressure is 6MPa, and the final sintering temperature is 1450°C, and then a large ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com