Plastic film production device and process thereof

A production device and mulch technology, applied in the field of plastic film production, can solve problems such as the unstable structure of the mulch length measuring device, the uncontrollable length of the broken film, and the waste gas pollution of the mulch cylinder, so as to achieve good clamping effect and reduce waste gas pollution , The effect of detachable device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be explained in detail below in conjunction with the accompanying drawings, so that those skilled in the art can better understand.

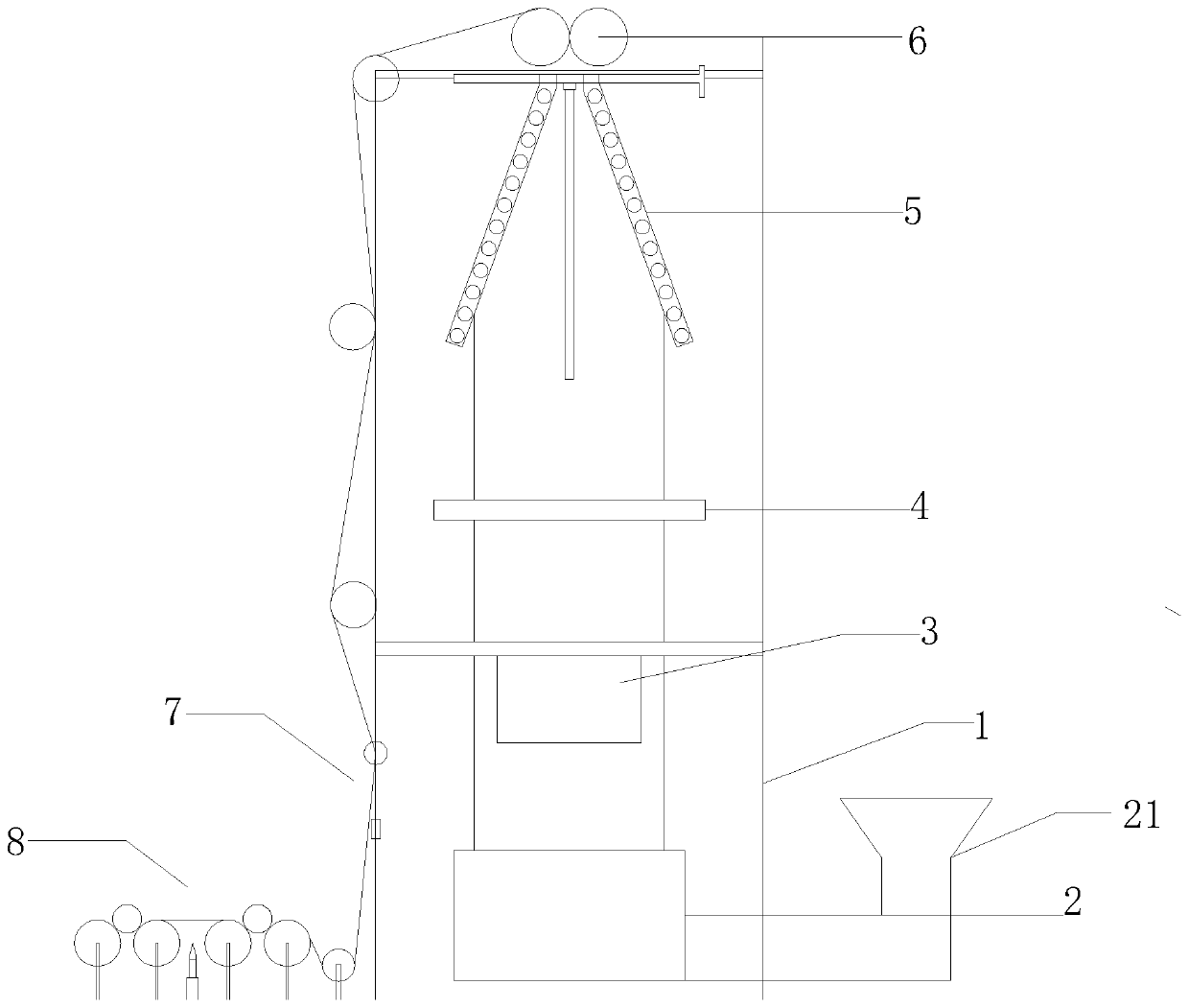

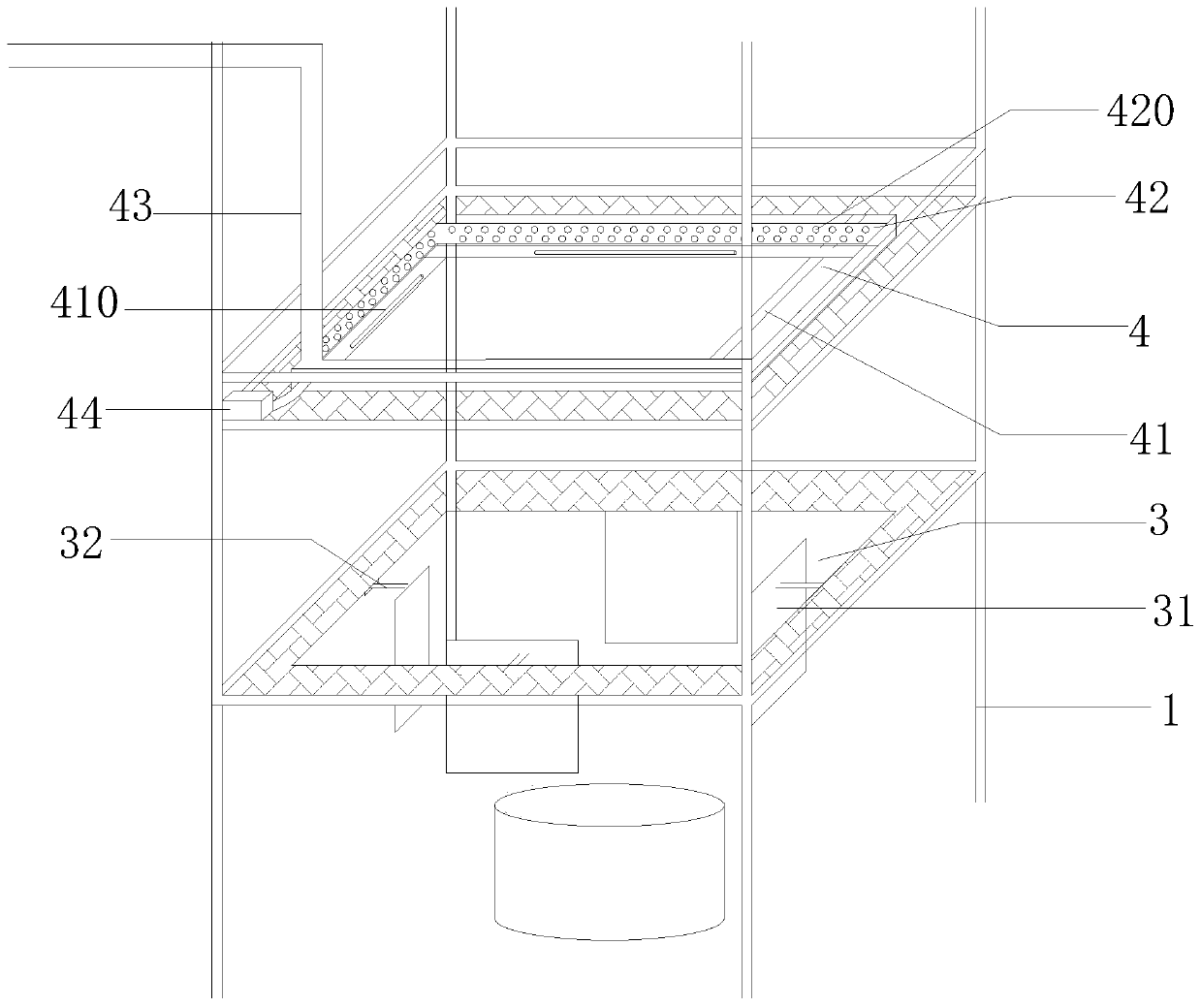

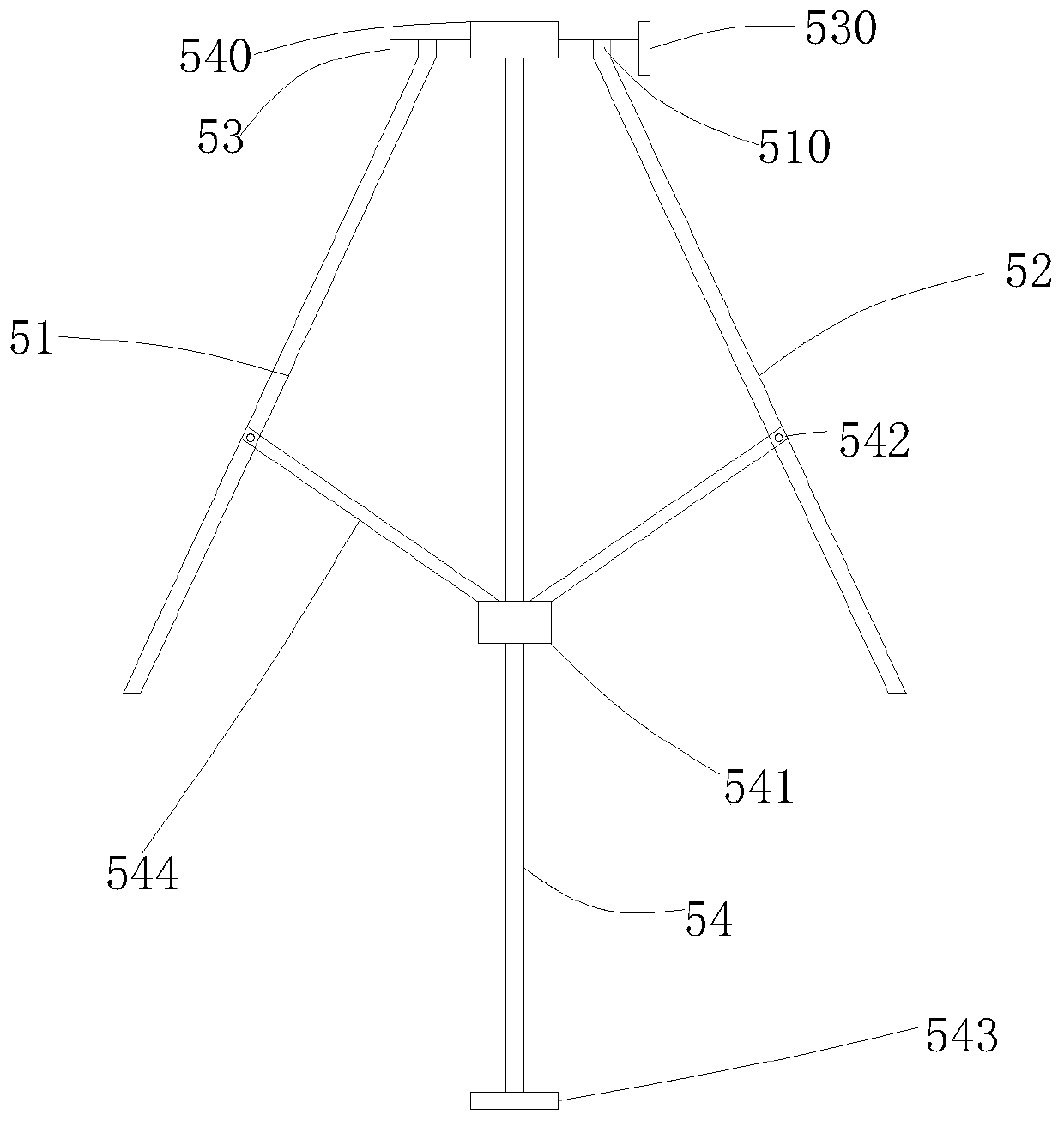

[0041] see figure 1 , a film production device and its technology, blow molding equipment in accordance with the film forming process includes: frame 1, blow molding machine 2, extruder 21, limit mechanism 3, air extraction device 4, herringbone plate 5, Traction device 6 , cutting device 7 and winding device 8 .

[0042] Add raw materials from the feeding port of the extruder. The raw materials are blown into a cylinder after being blown by the blow molding machine. The word plate, and then to the traction roller on the top of the frame, after being output from the traction roller, it moves downward along the outside of the frame. The middle cutter of the plastic film is set in the middle of the outer side of the frame, and the edge cutter of the plastic film is set below the middle cutter of the plastic film....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com