Laser printing machine for ceramic

A technology of laser printers and ceramics, which is applied in optics, electrical recording technology using charge graphics, equipment using electrical recording technology using charge graphics, etc. The head is easy to block and other problems, so as to overcome the frequent cleaning of the inkjet head, good fidelity, and simple after-sales maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

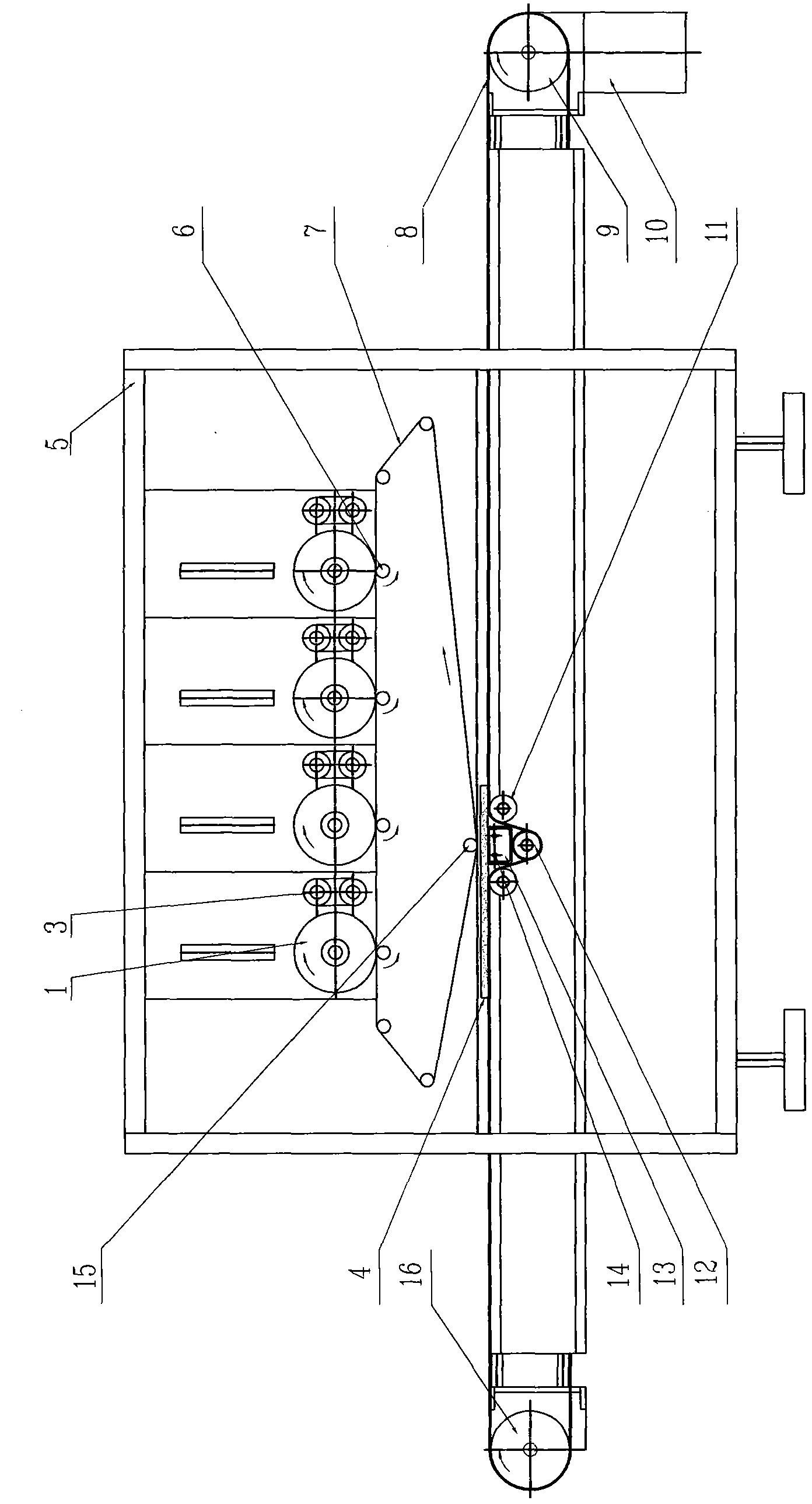

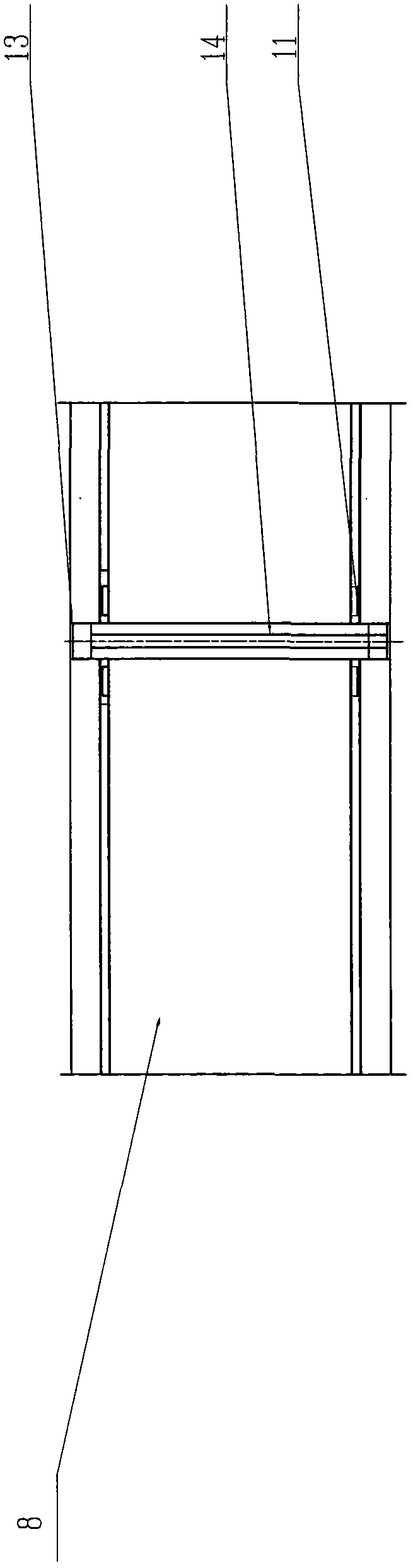

[0017] Embodiment one, see figure 1 and image 3 , between the first pad printing system and the ceramic adobe conveying system, there is a transfer belt 7 which rotates in circulation, and the lower part of the transfer belt 7 forms the closest point with the conveyor belt 8 of the ceramic adobe conveying system, and the closest point is formed by at least The second transfer roller 15 with negative static electricity is tensioned and formed. The closest point is not in contact with the upper surface of the ceramic tile adobe 4 conveyed, leaving a gap of 0.5-3 mm. A positive electrostatic field with a voltage of 2000-20000 volts is provided directly below the passage of the second transfer roller 15 corresponding to the ceramic tile adobe 4 at the closest point, and the positive electrostatic field is arranged longitudinally along the transfer belt 7. The wire seat 13 is formed, and the electrode wire 14 is passed through a high voltage to generate a positive electrostatic ...

Embodiment 2

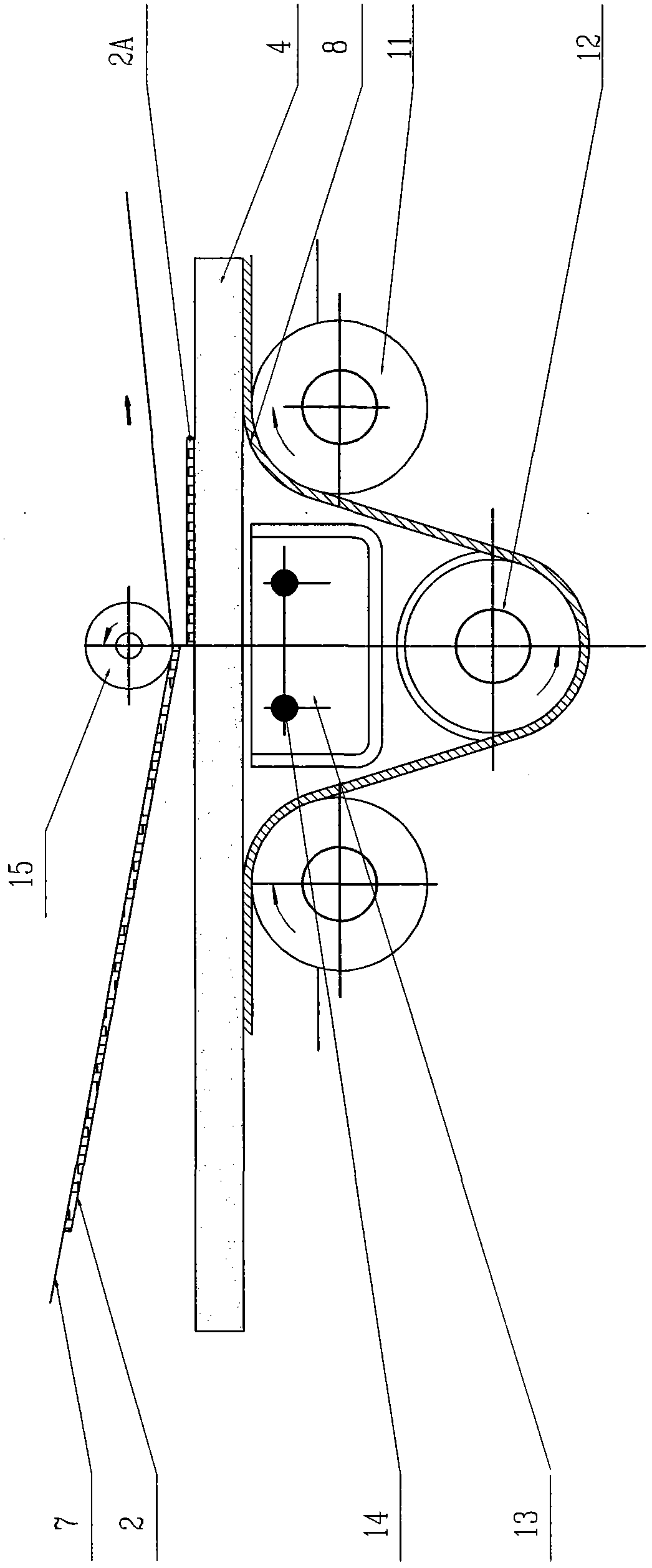

[0019] Embodiment two, see figure 1 and figure 2 , on the basis of the first embodiment above, in order to reduce the impact of the conveyor belt 8 on the electrostatic field, the conveyor belt 8 is improved, in particular: the conveyor belt 8 directly below the closest point corresponding to the transfer belt 7 , there are respectively provided with a pinch roller 12 and a guide roller 11 for changing the direction of the conveyor belt 8, and a pinch roller 2 and two guide rollers 11 are in a character-shaped layout, so that the conveyor belt 8 forms a partially concave space. The size matches the device for generating high-voltage static electricity. In this embodiment, the space can just place the electrode wire 14 and the electrode wire holder 13 . And the width of this partial depression of conveyer belt 8 is not big, does not influence the normal conveyance of conveyer belt 8 to ceramic brick 4, more importantly, the positive electrostatic field that it produces of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com