Patents

Literature

89results about How to "There will be no misalignment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

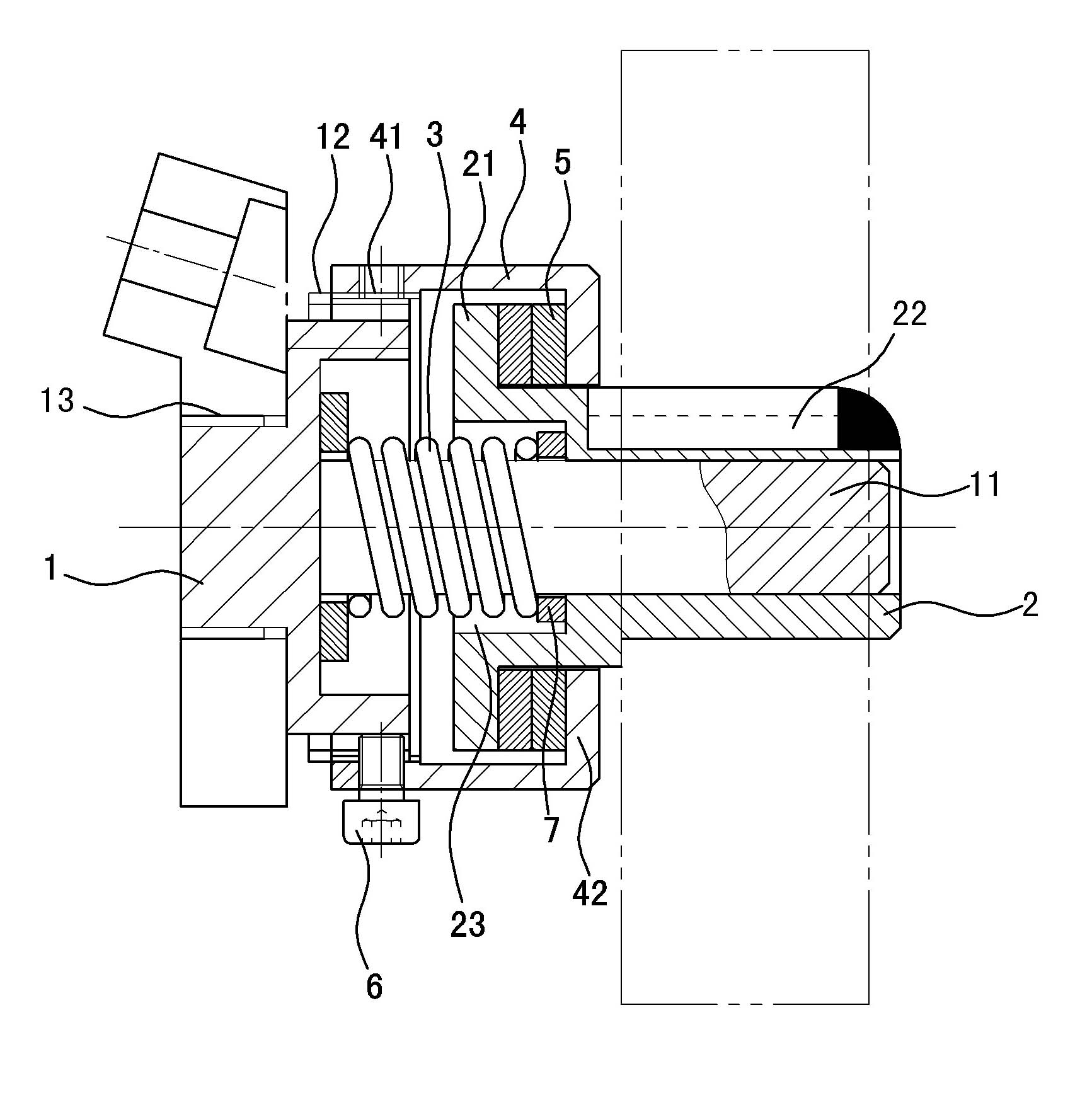

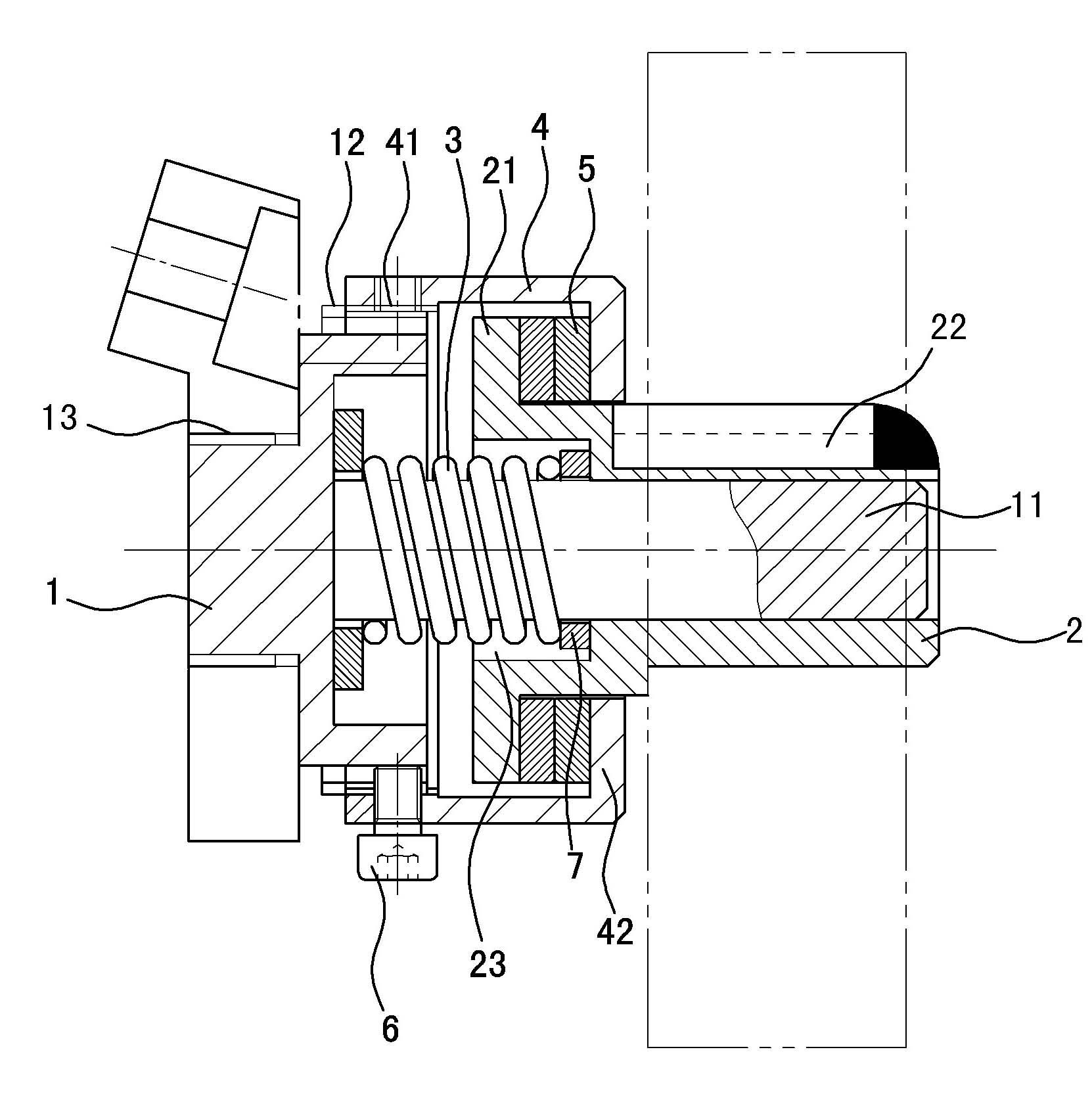

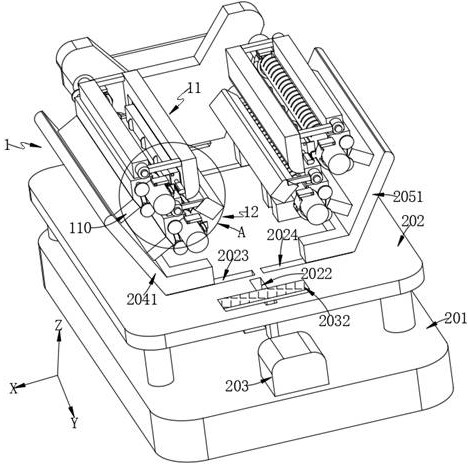

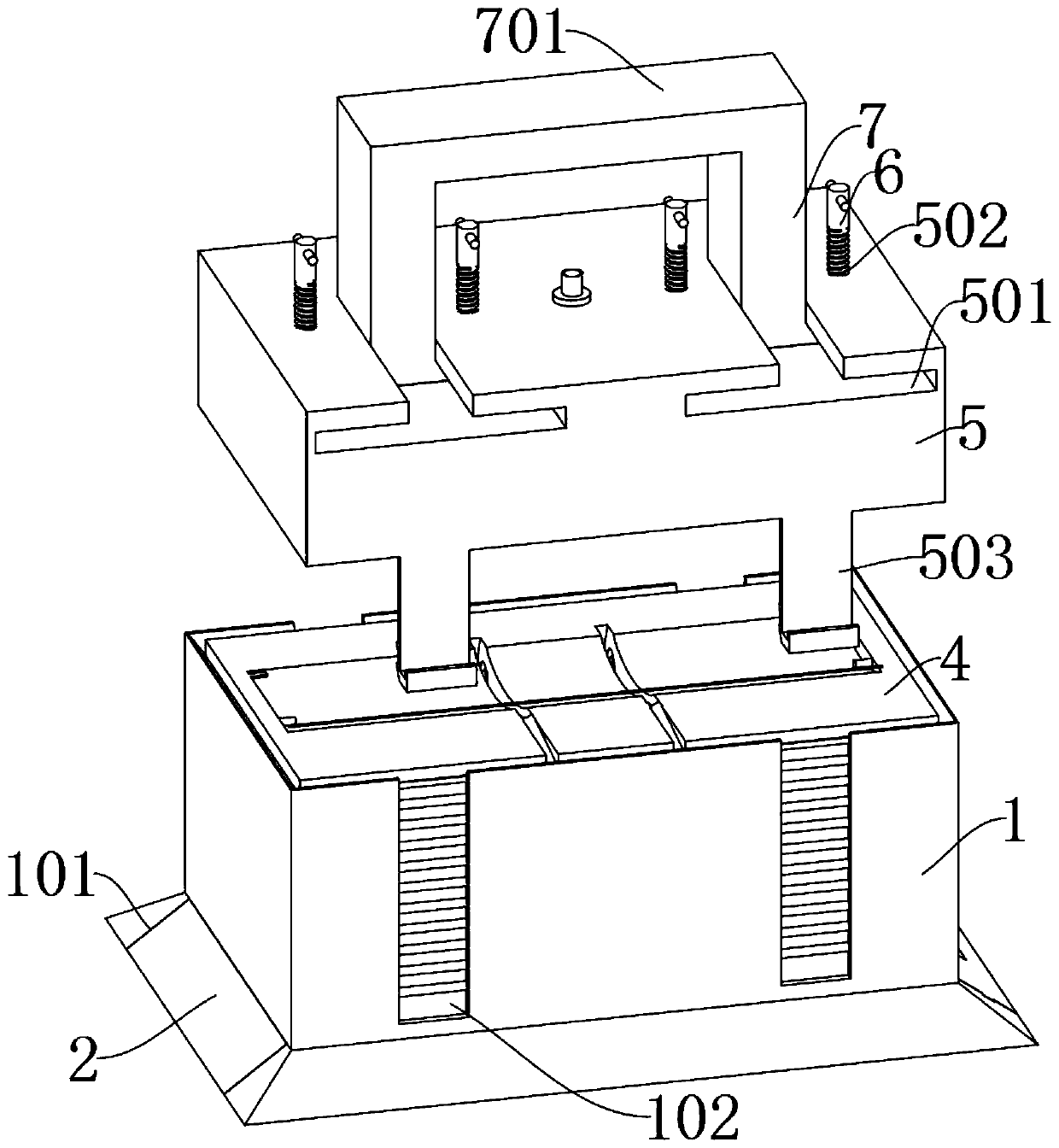

Adjustable guiding tension device of steel wire ring wrapping and winding machine

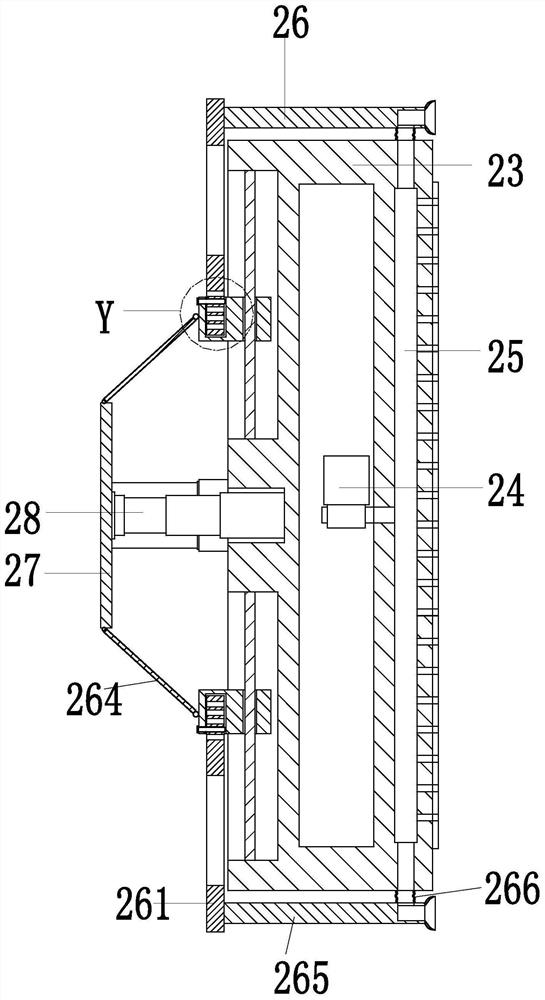

The invention relates to machinery equipment for tyre production, in particular to a steel wire ring wrapping and winding machine. The steel wire ring wrapping and winding machine comprises a fixed shaft base (1), a rotating base (2), a pressure spring (3), thread locking caps (4) and a plurality of friction sheets (5), wherein the pressure spring (3) is arranged between the fixed shaft base (1) and the rotating base (2) and sleeved on a central shaft (11) of the fixed shaft base (1); the friction sheets (5) are respectively sleeved on the rotating base (2); the thread locking cap (4) are sleeved on the rotating base (2) and the plurality of friction sheets (5); and the end parts of the thread locking caps (4) are connected to the fixed shaft base (1) through threads. The steel wire ring wrapping and winding machine has the advantages of adjustable tension force, large and uniform enough tension force, firmness and durability. A steel wire ring is wound and wrapped by using the steel wire ring wrapping and winding machine so as to achieve the expected effect of consistent tightness wrapping and uniform tension force, thereby the machine is suitable for the steel wire ring winding and wrapping process for rubber tyre production, and the tension force of the steel ring wound and wrapped by the steel wire ring wrapping and winding machine can be enhanced.

Owner:桦林佳通轮胎有限公司

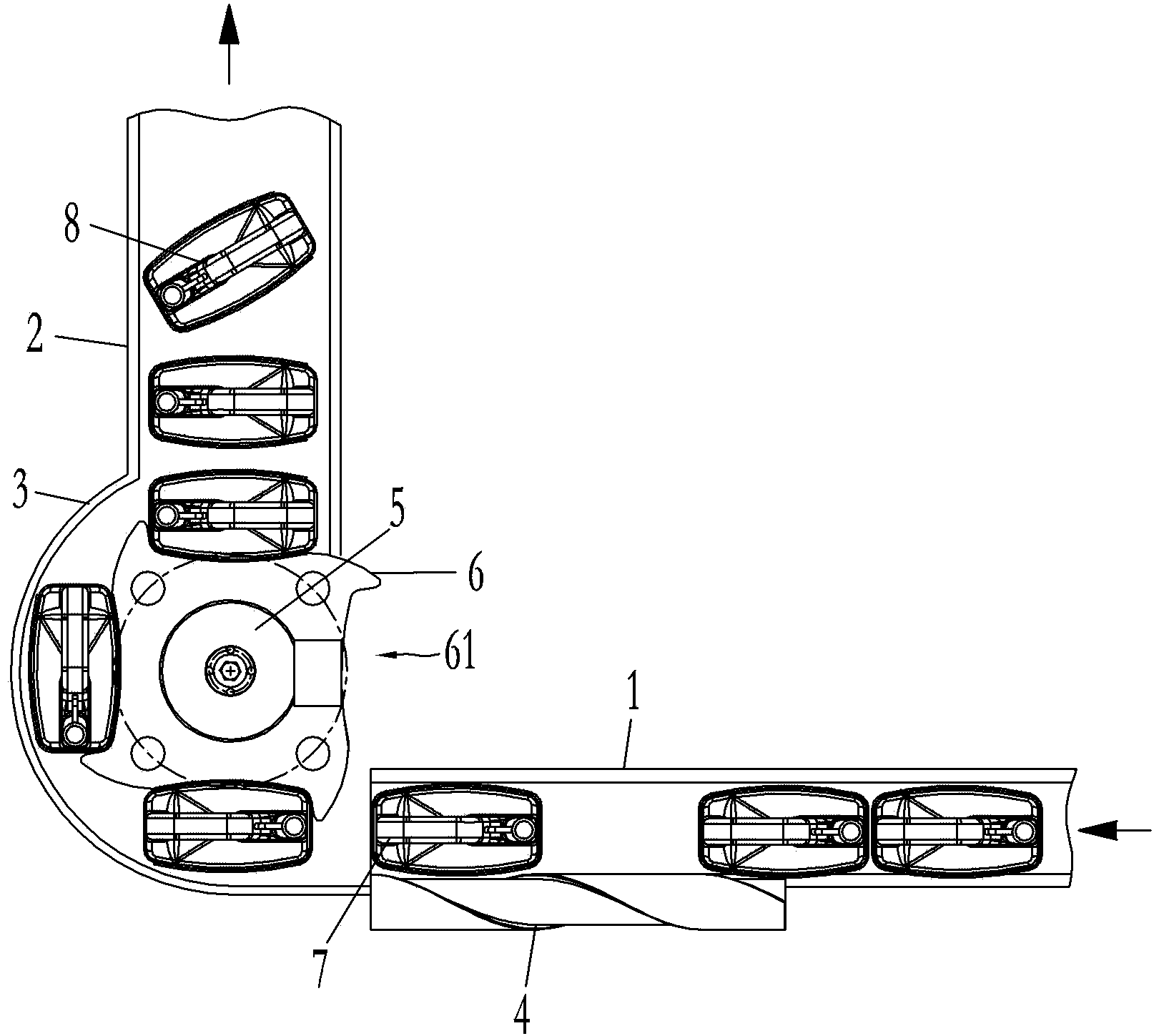

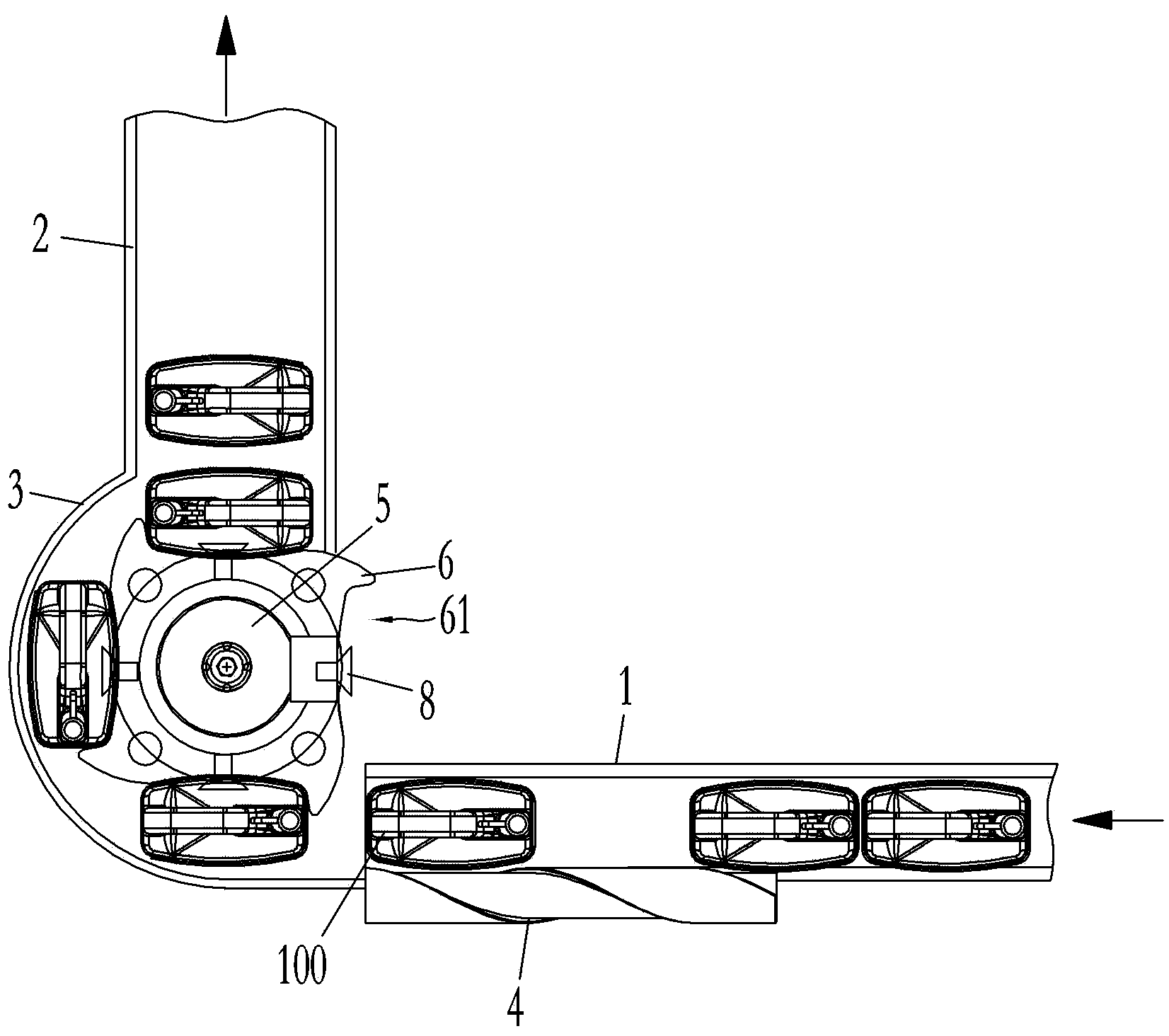

Bottle steering mechanism

The invention discloses a bottle steering mechanism. A sucker is arranged between a pusher dog on the lower portion of a rotating device and a push dog on the upstream portion of the rotating device. A vacuum device is arranged to be matched with the sucker. The sucker can suck the bottle entering the bottle steering mechanism through an upper conveying device and clamped into a clamping groove of the sucker, and loosen the bottle when the bottle is made to rotate to a preset position by the pusher dogs of the rotating device, so that the condition of non-straight position cannot occur when the bottle is transited to a downstream conveying device. Moreover, the bottle is conveyed out by the downstream conveying device, so that the rotating speed of the rotating device and the conveying speed of the conveying devices can be adjusted to be uniform without spending a large amount of time.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

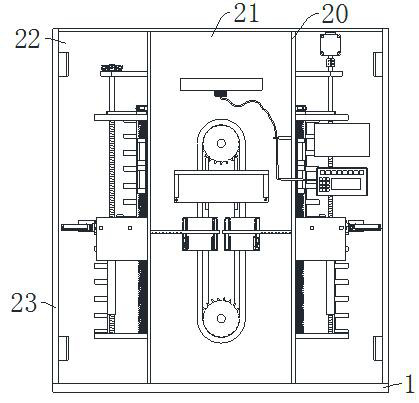

Laser printing machine for ceramic

The invention relates to a laser printing machine for ceramic. The laser printing machine comprises a stander, a first transfer printing system and a ceramic green brick conveying system, wherein the first transfer printing system comprises at least one selenium photosensitive drum, a ceramic toner with negative static electricity, a laser head and a transfer printing roller; a circulating rotating transfer printing band is arranged between the first transfer printing system and the ceramic green brick conveying system; a closest point to the ceramic green brick conveying system is formed on the lower part of the transfer printing band and is not in contact with the upper surface of a ceramic green brick passing through the closest point, and a clearance of 0.5-3 mm is reserved between the closest point and the upper surface of the ceramic green brick; a positive static electric field capable of adsorbing the ceramic toner with the negative static electricity on the transfer printing band to the surface of the ceramic green brick is arranged just under a position, through which the ceramic green brick corresponding to the closest point passes; the voltage of the positive static electric field is 2,000-20,000 V. Due to the design, the definition and the vividness of pattern lines printed on the surface of the ceramic green brick can be greatly improved, and the color quality of a ceramic brick is improved; meanwhile, after-sale productive maintenance of equipment is reduced, the production efficiency is improved, and the production cost is lowered.

Owner:陆永添

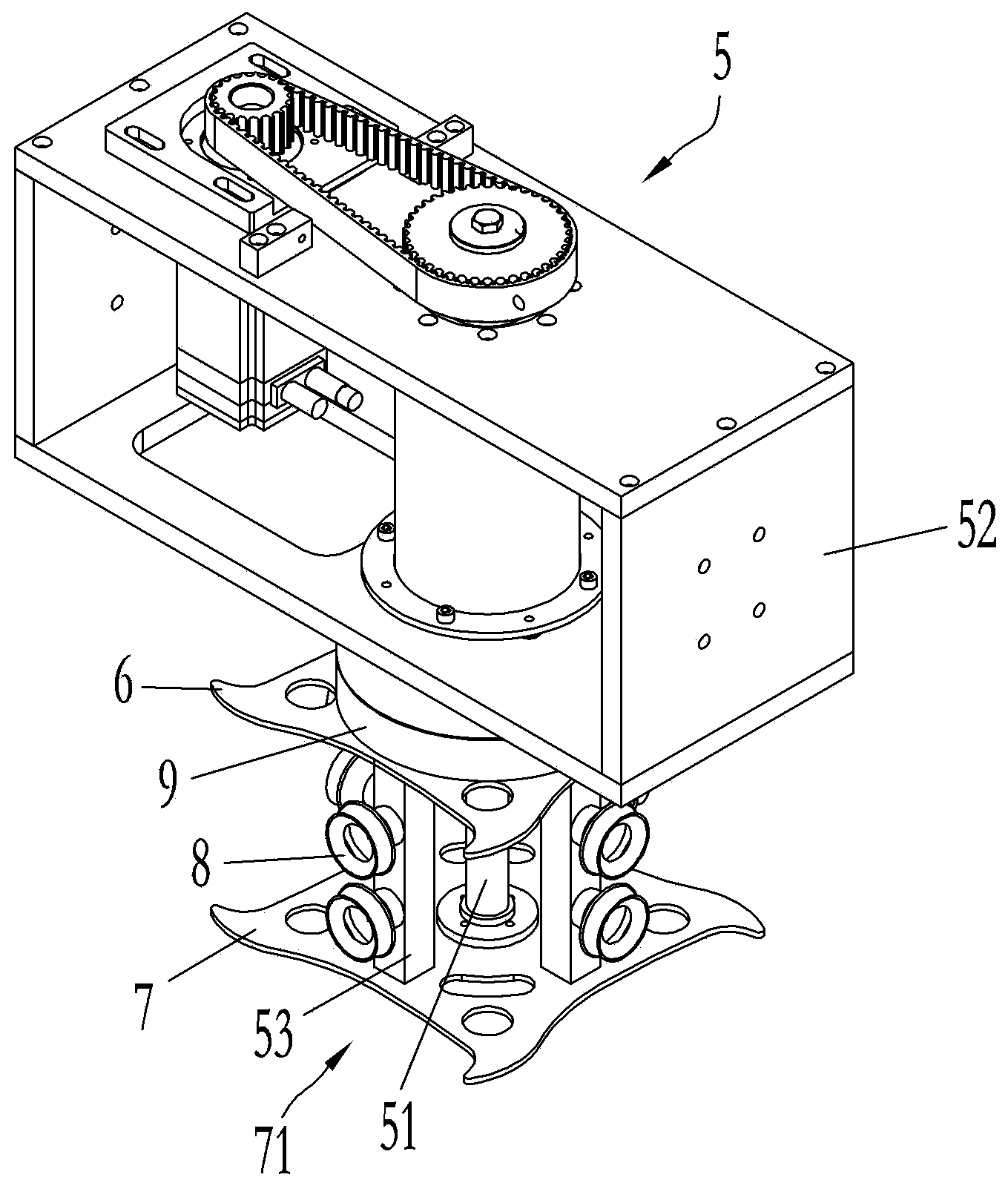

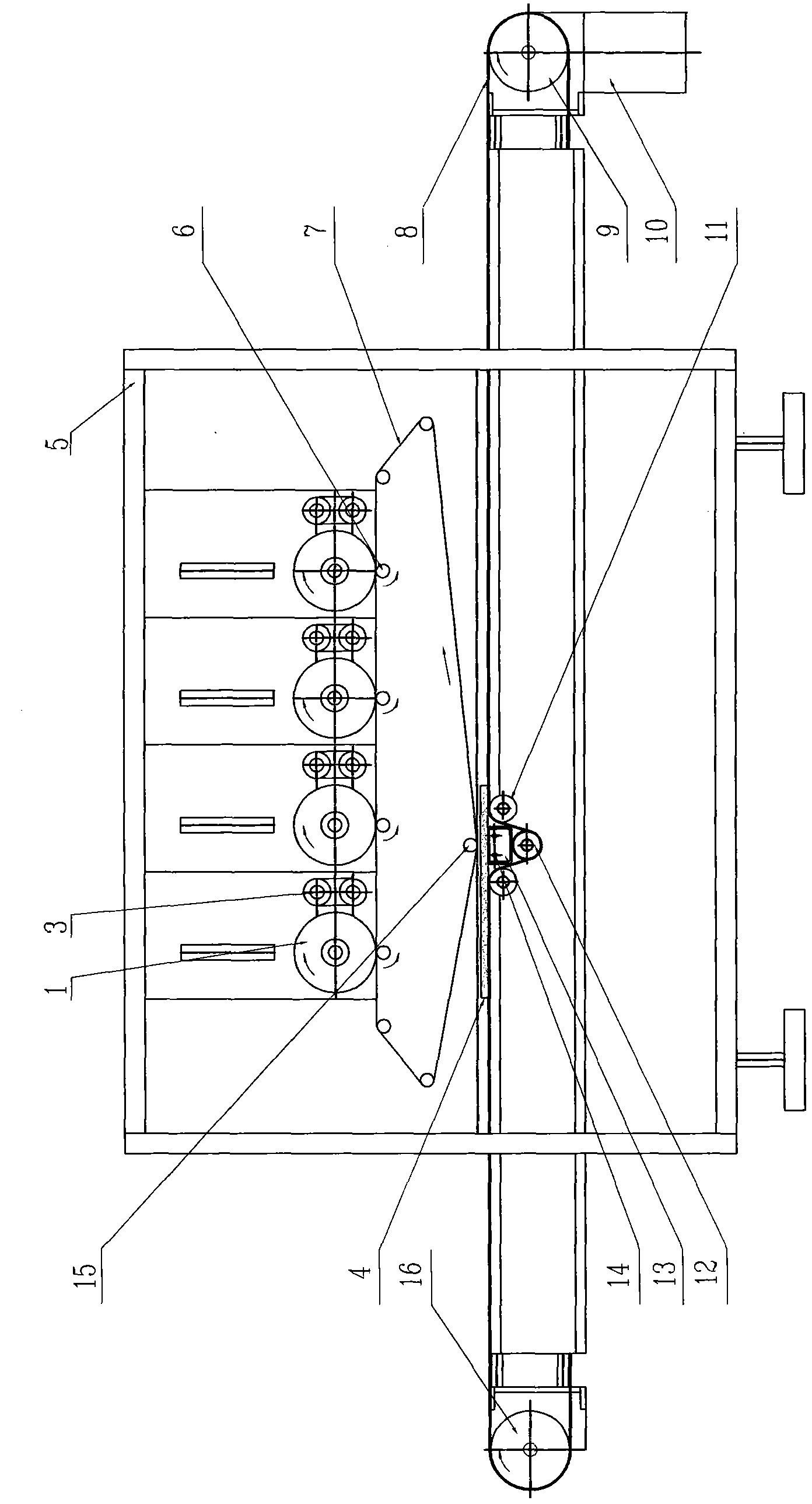

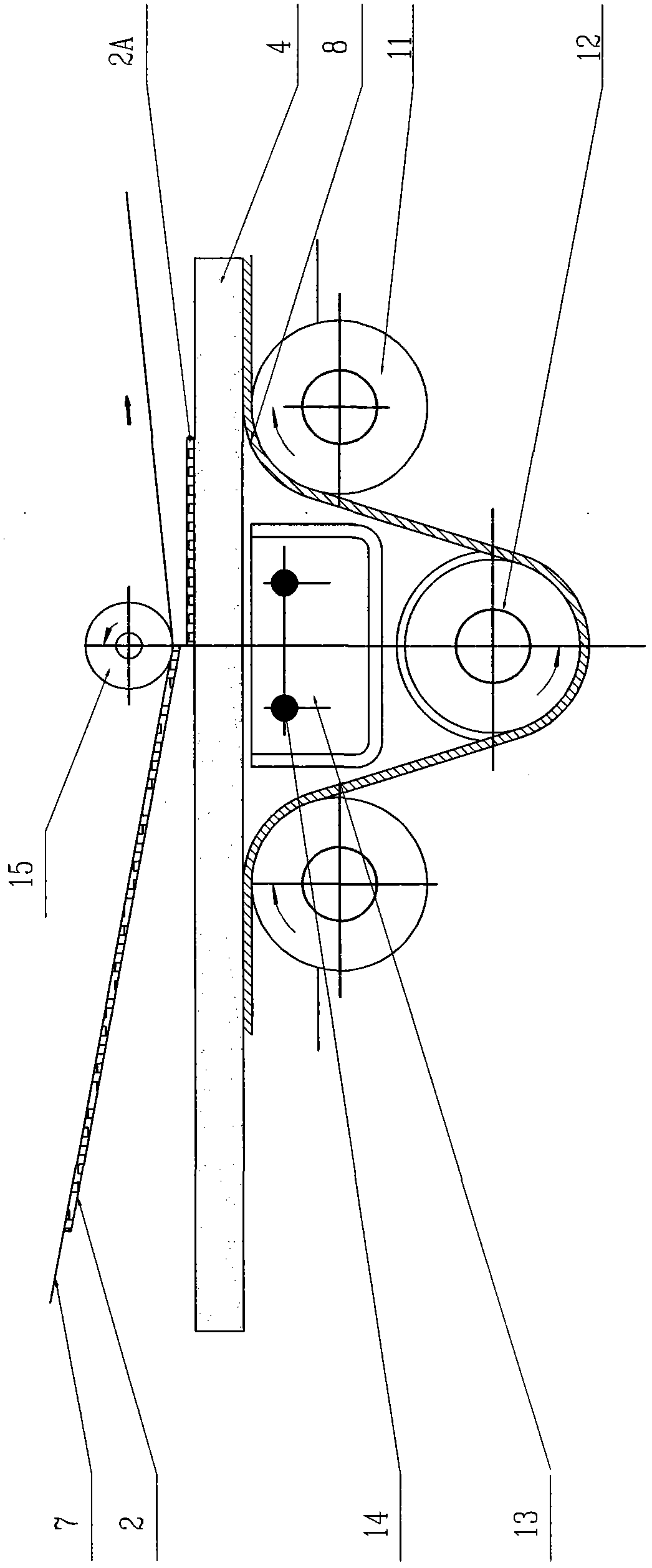

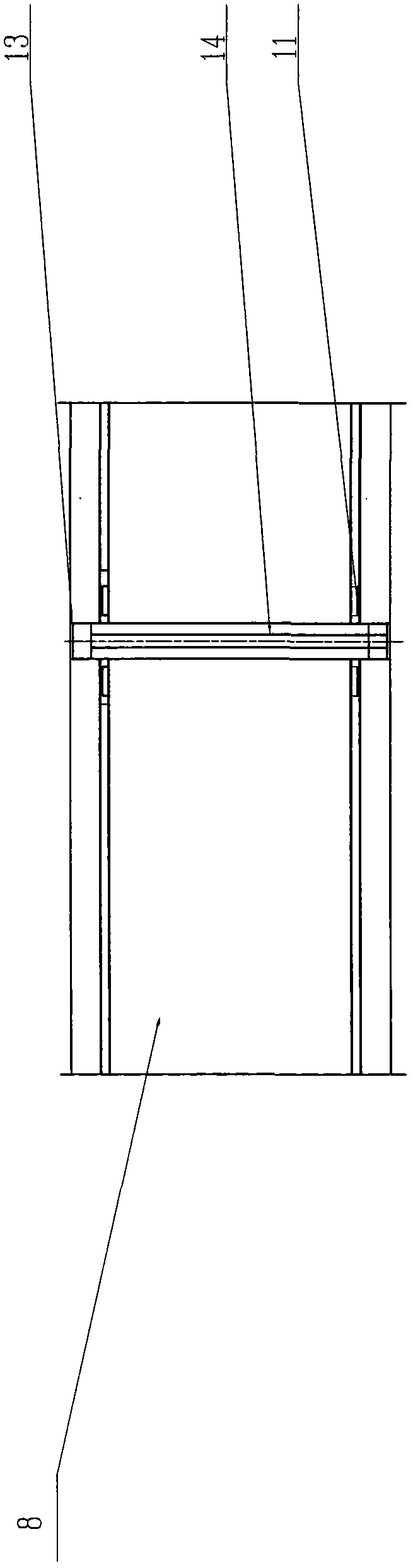

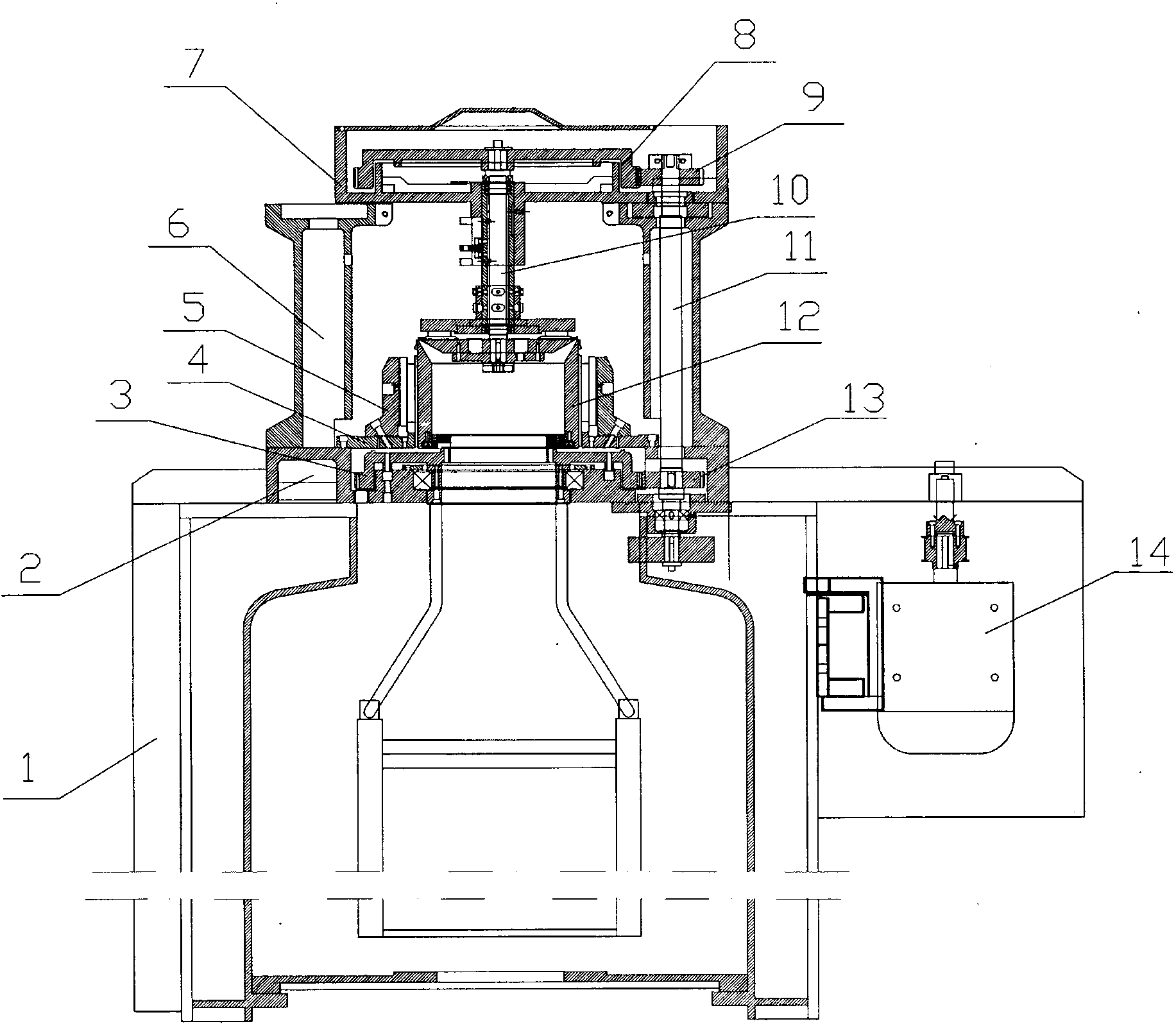

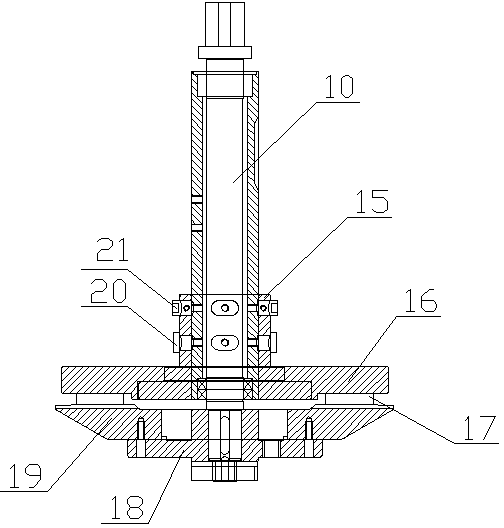

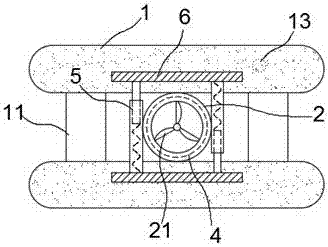

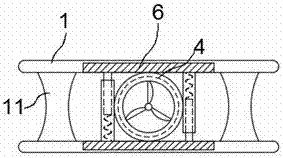

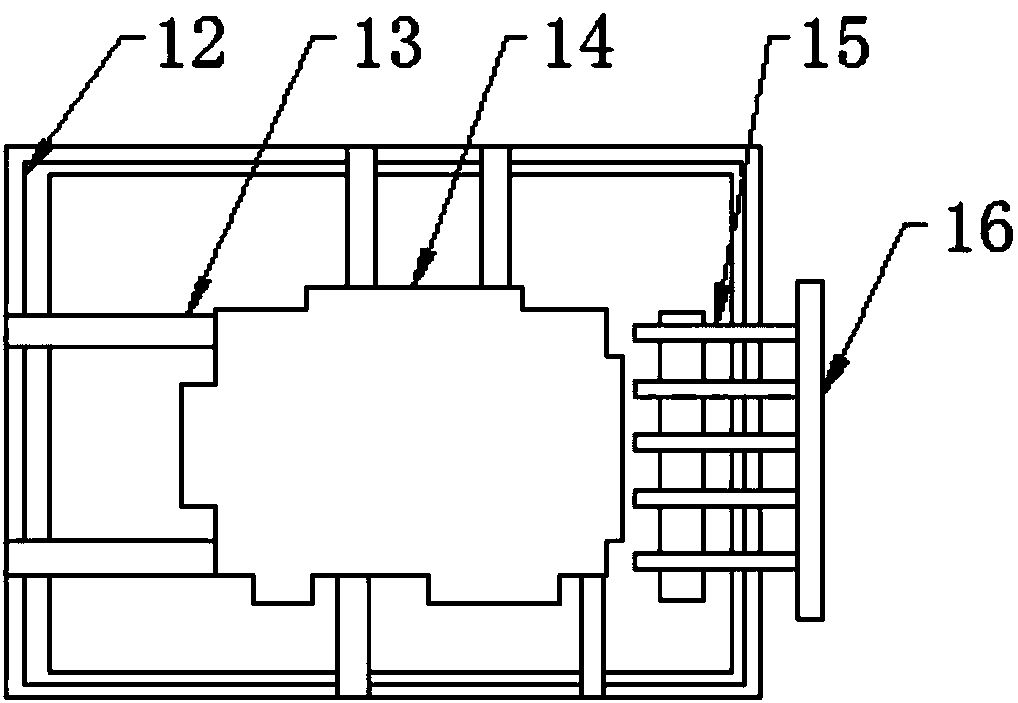

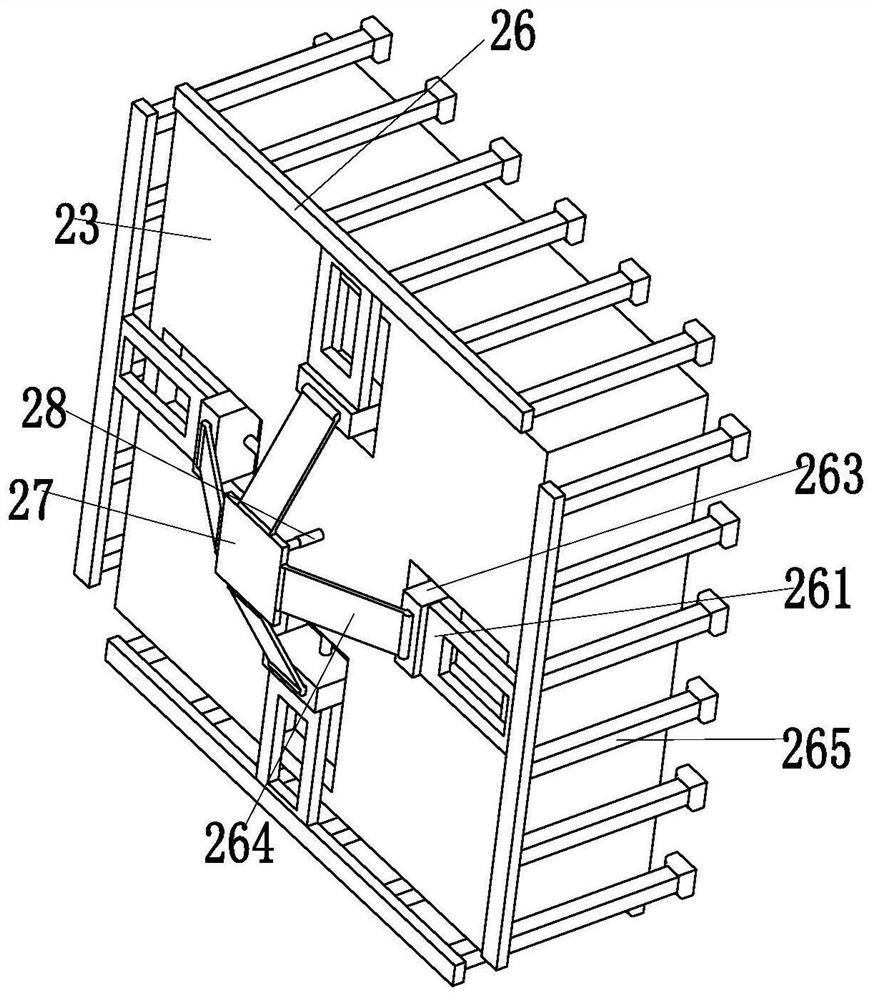

Knitted double-sided machine

The invention discloses a knitted double-sided machine. The knitted double-sided machine comprises a support, a large pot and a large disk, a large pot gear is arranged on the large pot, a downward-arranged gun barrel is connected coaxially in the middle of the large pot gear, the bottom end of the gun barrel is connected with a needle plate seat through keys, and the needle plate seat is connected with a needle plate through screws and jackscrews. A large disk gear is arranged on the large disk, wherein the number of the teeth of the large disk gear is equal to the number of the teeth of the large pot gear, and a needle cylinder is connected in the middle of the large disk gear coaxially. A transmission gear is arranged between the large disk gear and the large pot gear, the transmission gear comprises an adjustable gear meshed with the large pot gear and a primary drive gear meshed with the large disk gear, a main transmission shaft is arranged between the adjustable gear and the primary drive gear, and the primary drive gear is connected with a motor through a transmission belt. The knitted double-sided machine enables the needle cylinder and the needle plate to rotate synchronously through gear transmission, and is capable of achieving high-speed accurate transmission in the oil-immersed environment. In addition, the phenomenon of misplacement of an upper needle and a lower needle can not occur, and knitted fabric of a high density can be knitted.

Owner:LIANYUNGANG YUANFENG MACHINERY

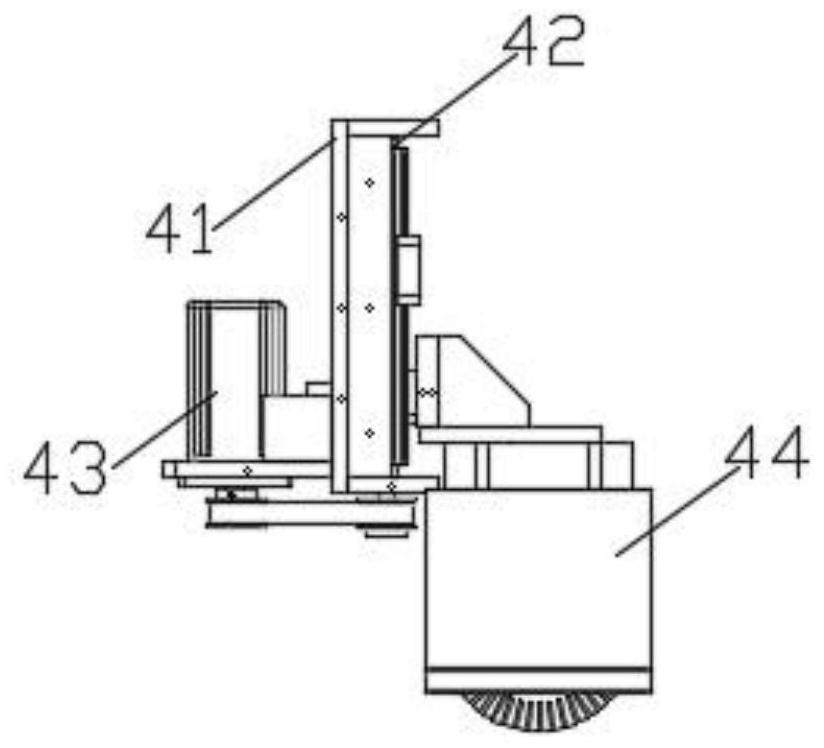

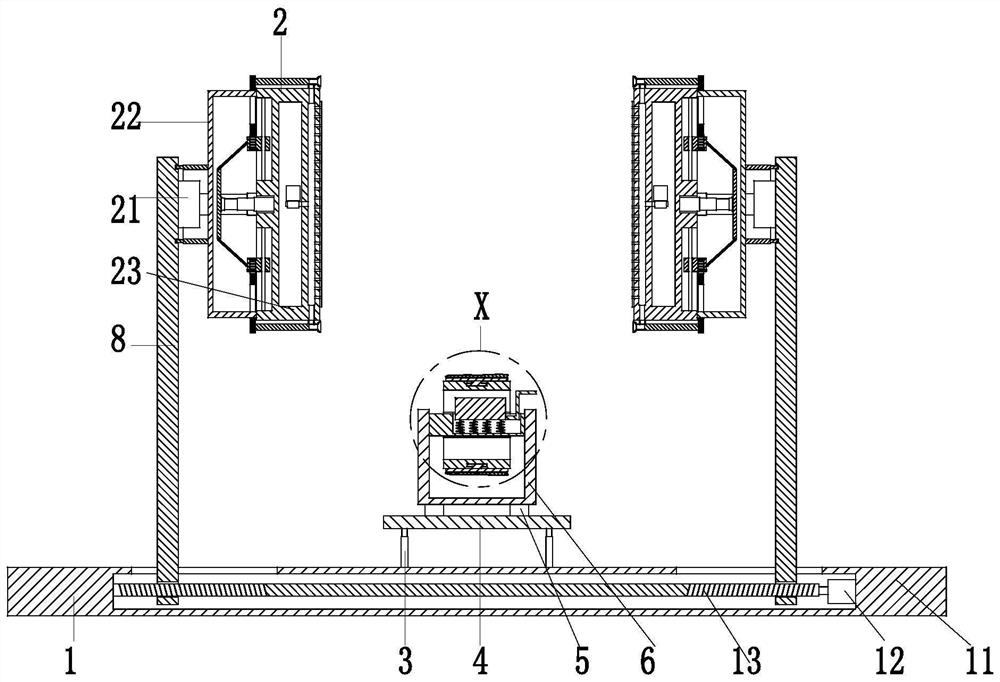

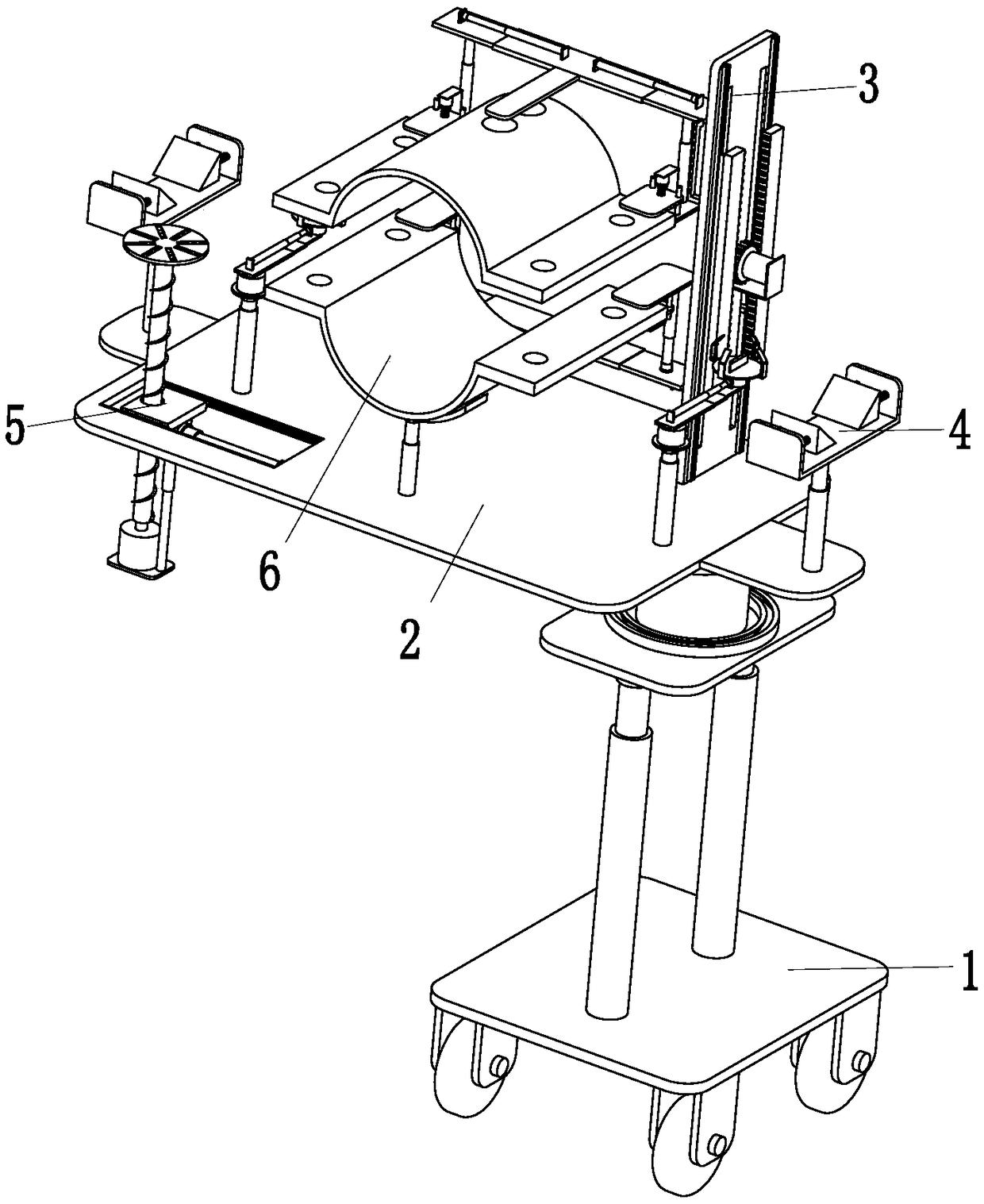

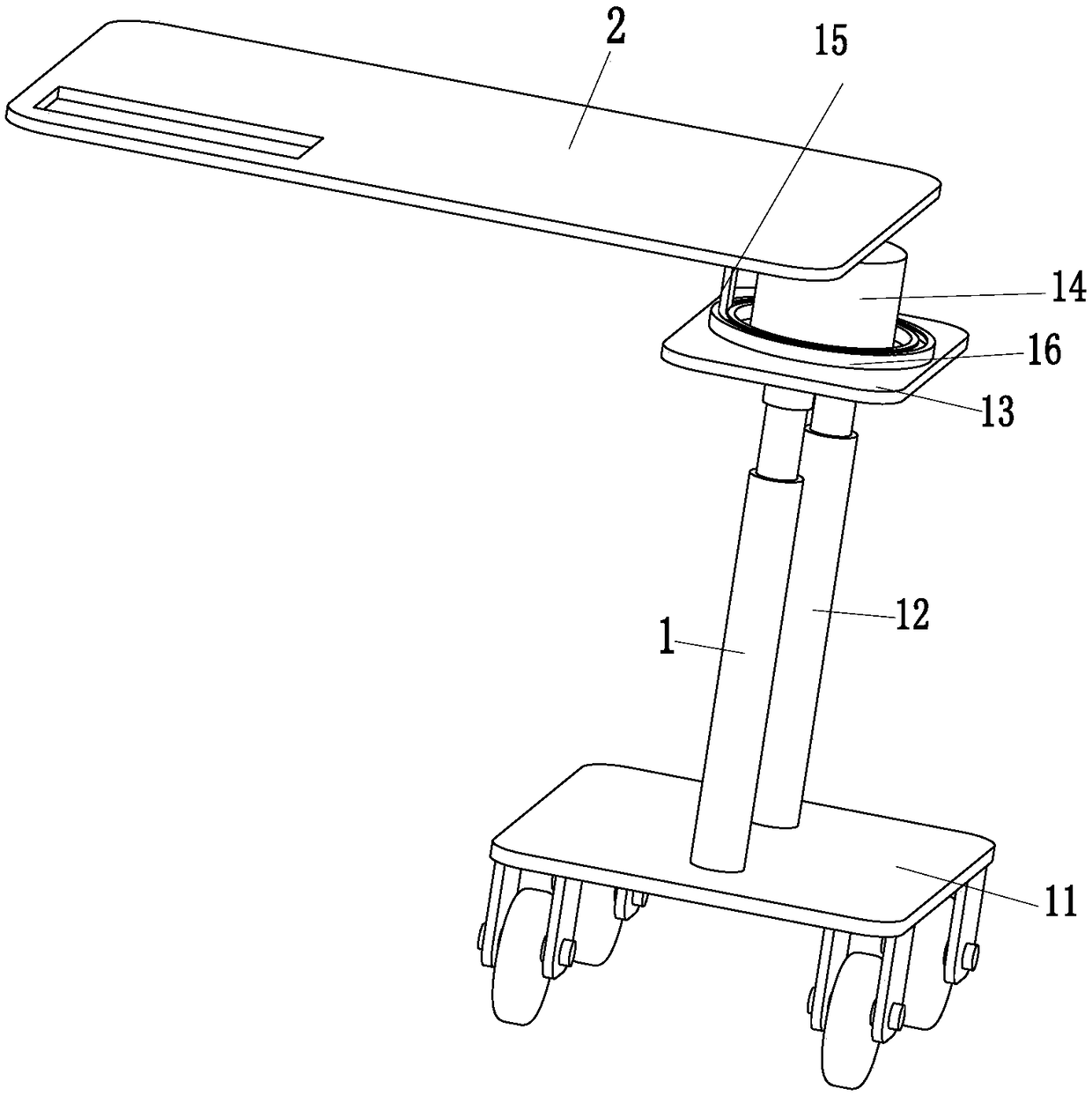

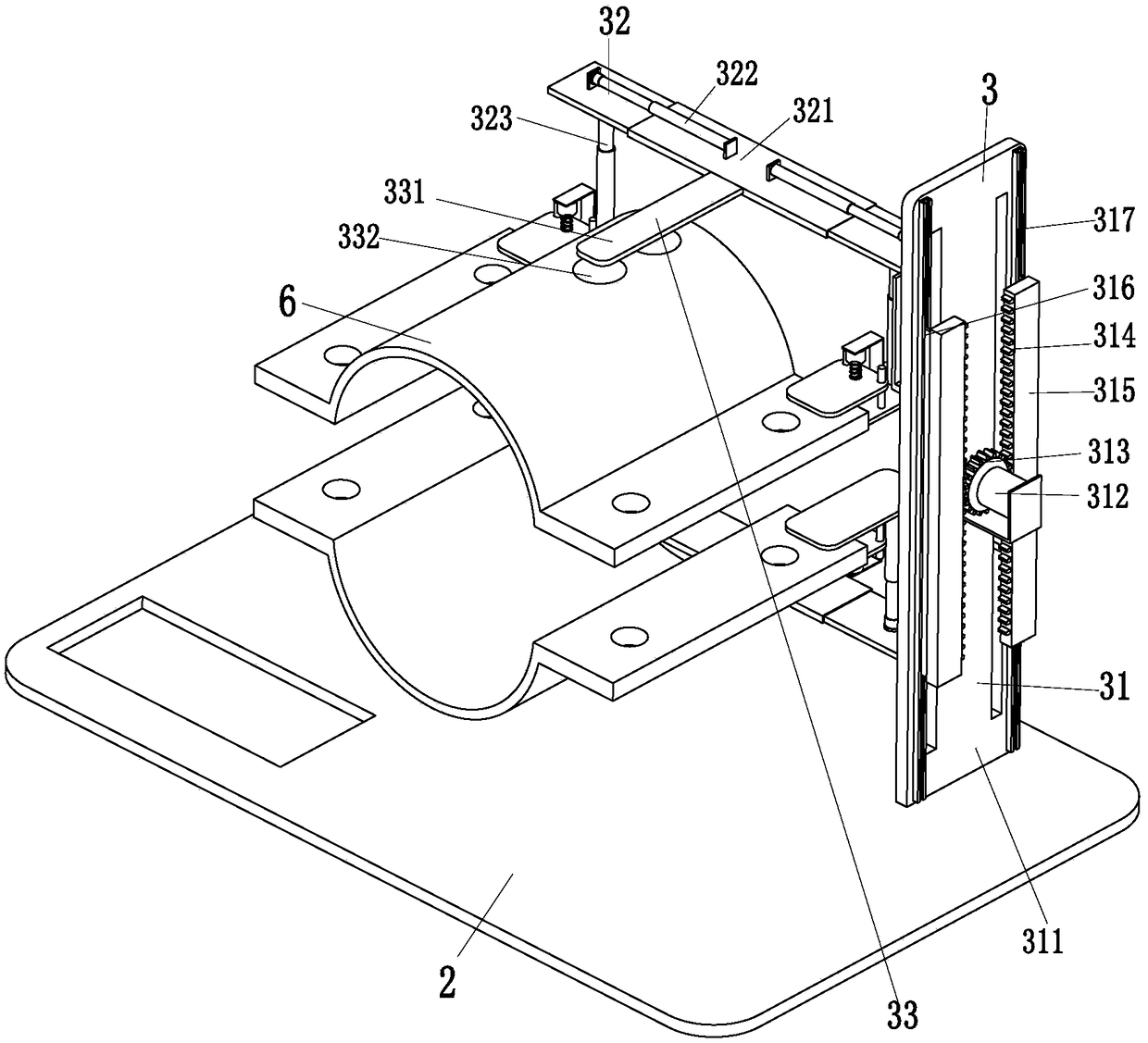

Automatic polishing facility for abnormally-shaped plate machining and working method of automatic polishing facility

InactiveCN112008558AImprove polishing efficiencyReduce wasteGrinding carriagesBelt grinding machinesPolishingEngineering

The invention discloses an automatic polishing facility for abnormally-shaped plate machining and a working method of the automatic polishing facility. According to the polishing facility, a surface polishing mechanism and a side face polishing mechanism are arranged on the two sides of a rotating mechanism, and therefore the polishing efficiency of an abnormally-shaped plate is higher; the abnormally-shaped plate does not need to be moved in the process of polishing the surface and the side face, and therefore the time wasted by movement of the abnormally-shaped plate is greatly shortened; and the requirement for polishing of the upper surface and the side face of the abnormally-shaped plate can be met. Due to the design of a negative pressure suction disc on a rotary supporting plate, side edge fixing does not need to be conducted when the upper surface of the abnormally-shaped plate is polished, the technical problem that when the side face of a plate is fixed, polishing of the upper surface of the plate can be resisted and affected is solved. Meanwhile, when the side face of the abnormally-shaped plate is polished, the situation that the abnormally-shaped plate cannot be misplaced when the side face of the abnormally-shaped plate is polished is guaranteed through fixing absorption of the top and the bottom of the abnormally-shaped plate, and the facility meets the requirement for polishing of the various abnormally-shaped plates and is high in applicability.

Owner:程晋芹

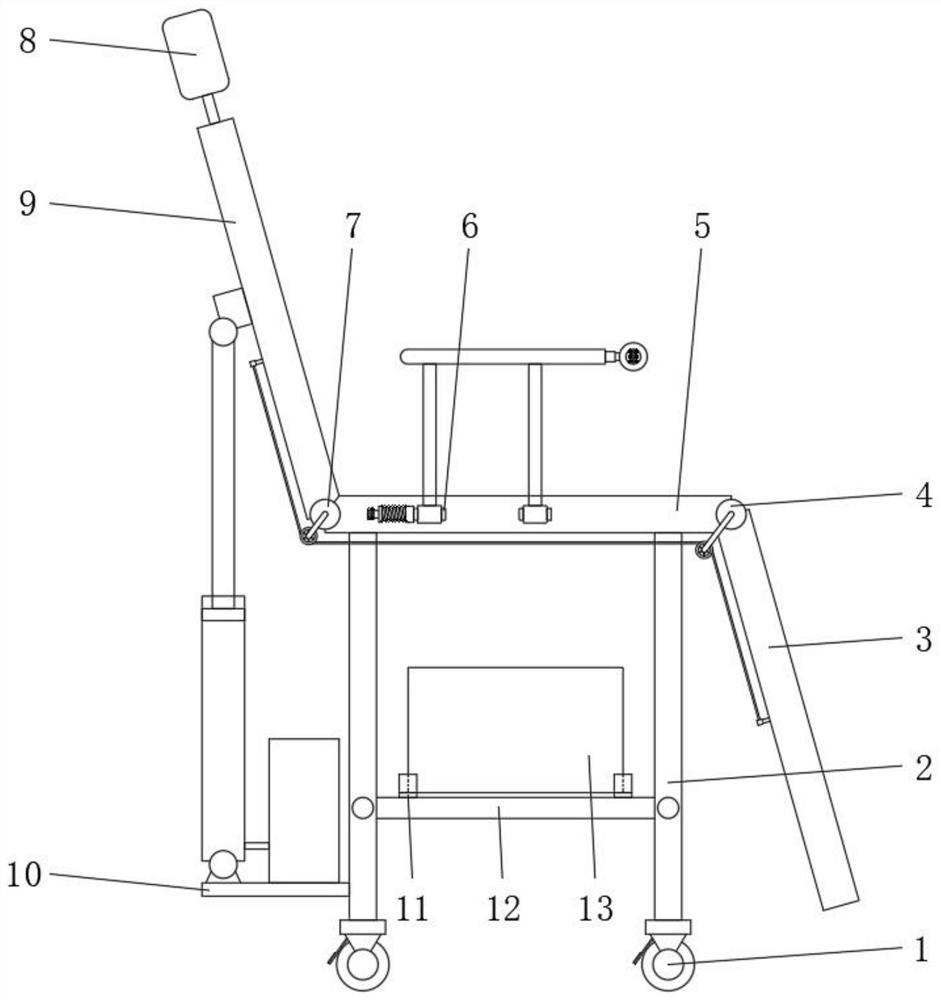

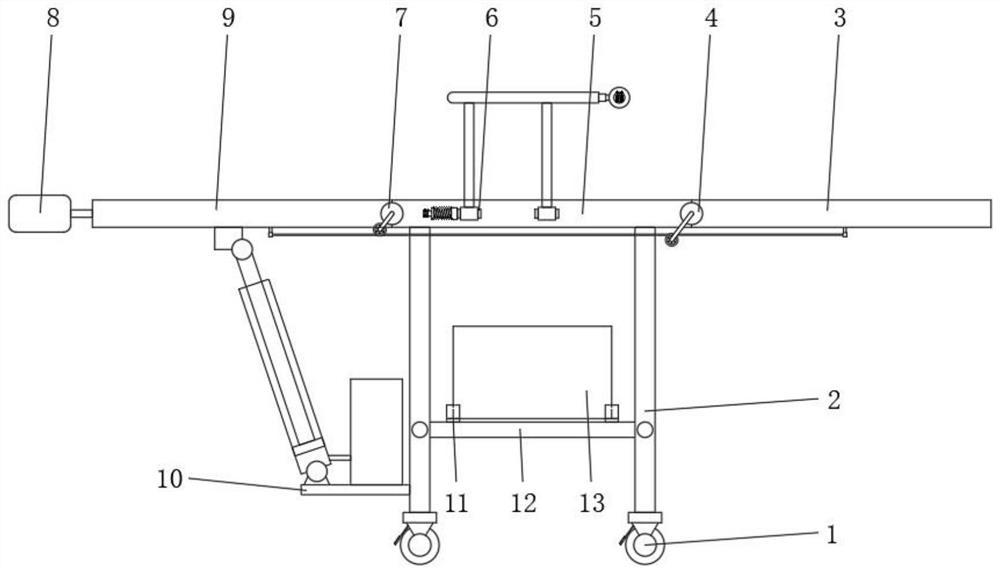

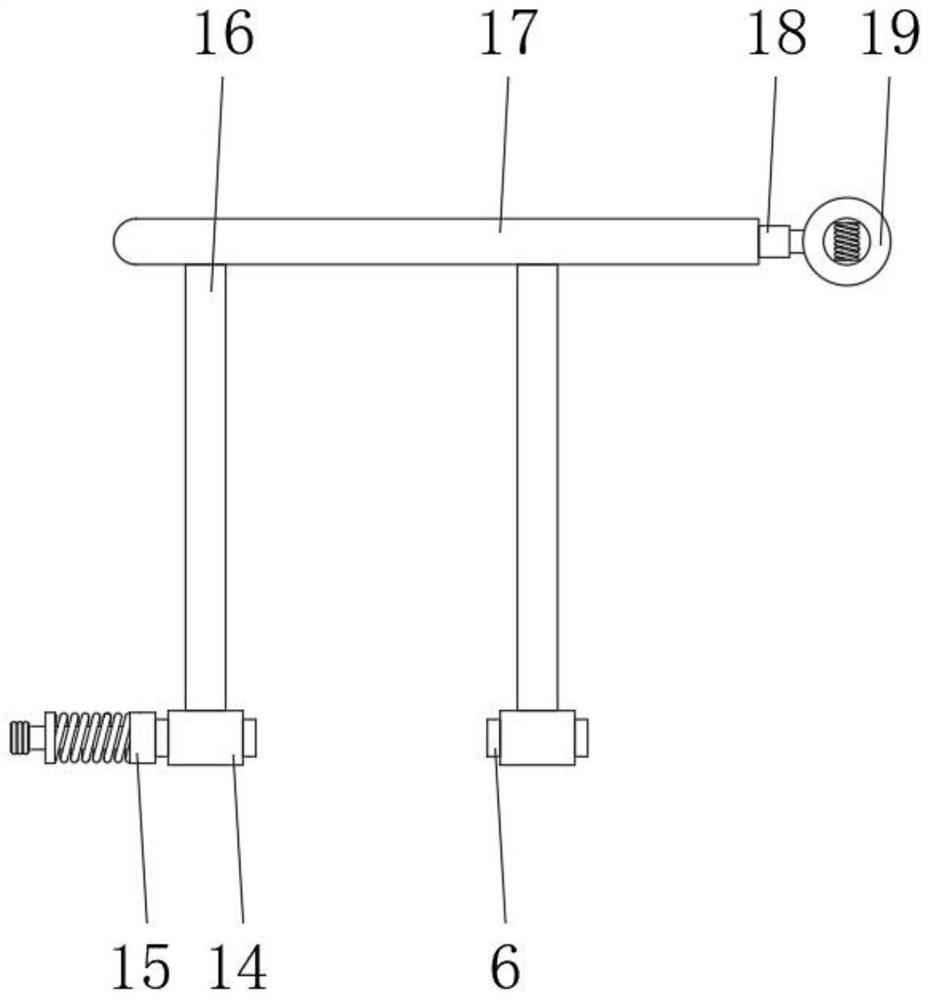

Internal medical clinical multifunctional training device

InactiveCN111888110AEasy to flip and placeEasy to placeGymnastic exercisingChiropractic devicesHydraulic cylinderPhysical medicine and rehabilitation

The invention discloses an internal medical clinical multifunctional training device. The internal medical clinical multifunctional training device comprises supporting legs, a leg supporting plate, amiddle plate and a back supporting plate, wherein the supporting legs are welded to the lower surface of the middle plate; the leg supporting plate is installed on one side of the middle plate through a connecting shaft A, and the back supporting plate is installed on the other side of the middle plate through a connecting shaft B; a headrest is mounted at the tail end of the back supporting plate; and a hydraulic mounting plate is mounted at the lower end of the outer side of the supporting leg close to one side of the back supporting plate. The internal medicine clinical multifunctional training device can be conveniently unfolded and folded through assemblies of the hydraulic cylinders so as to train the waist and leg functions of a patient, the patient can be protected through an armrest rod capable of being rotationally assembled and disassembled, training equipment at the tail end of the armrest rod can be replaced, and the hand functions of the patient can be trained.

Owner:THE FOURTH PEOPLES HOSPITAL OF GUIYANG

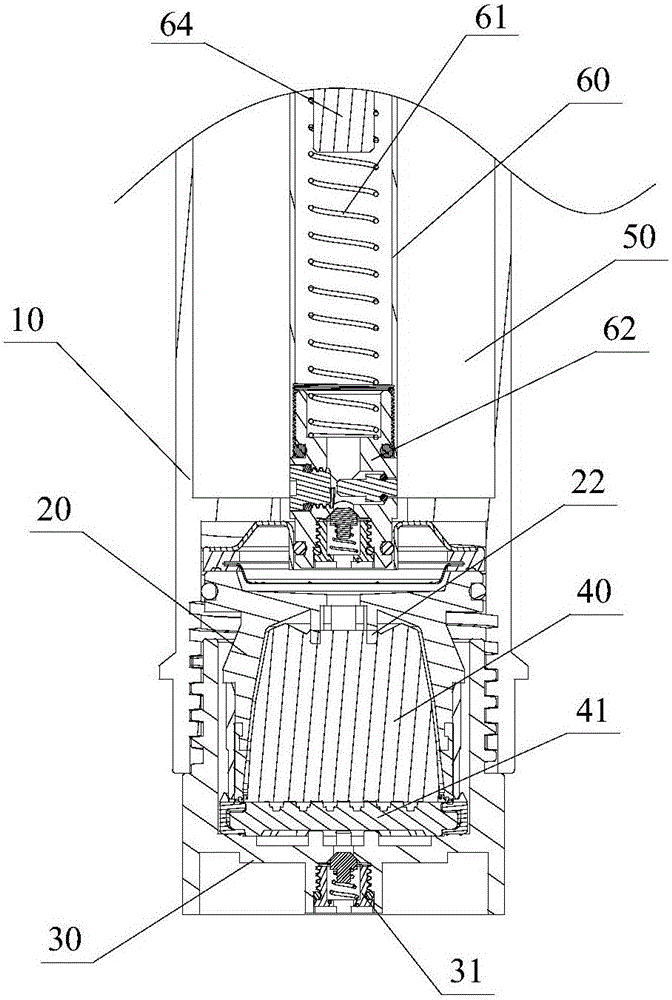

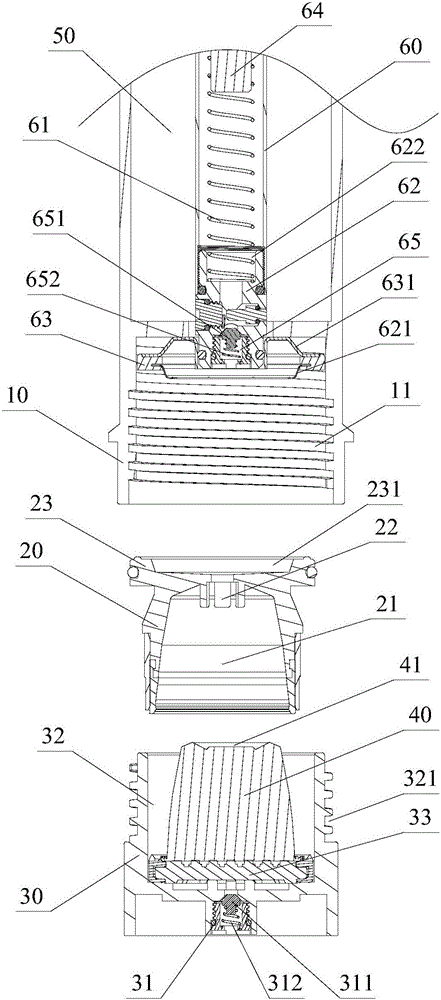

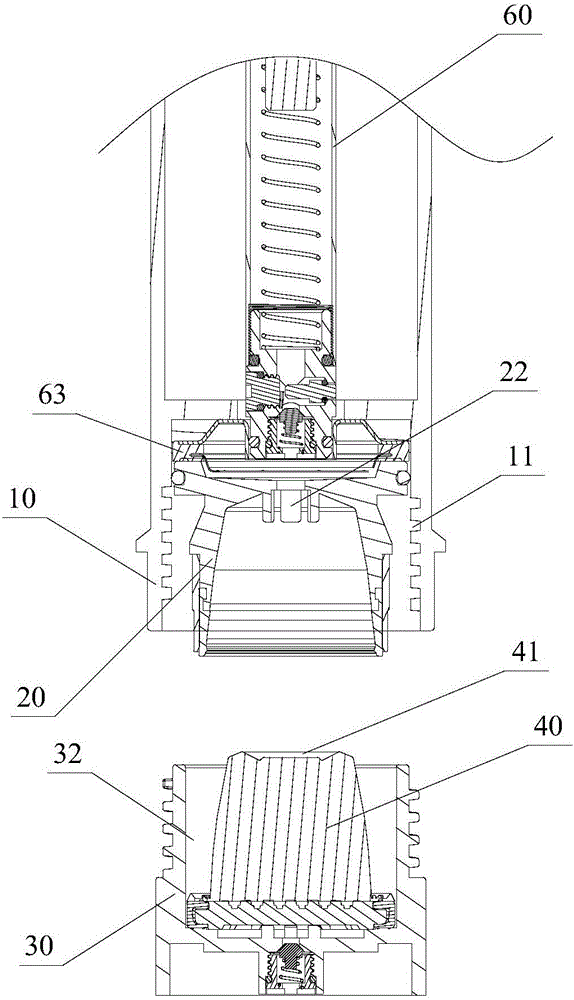

Hand pressing capsule coffee machine

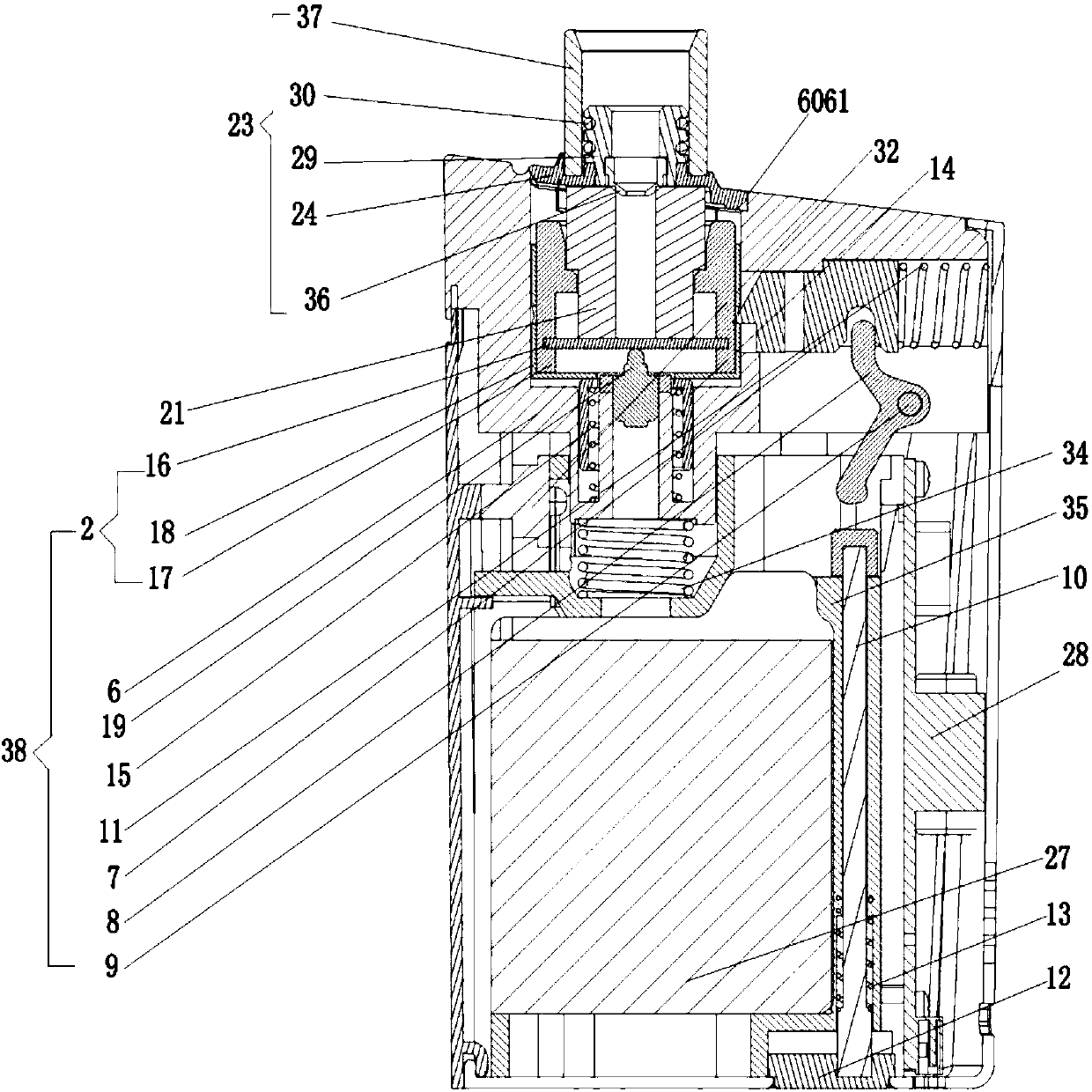

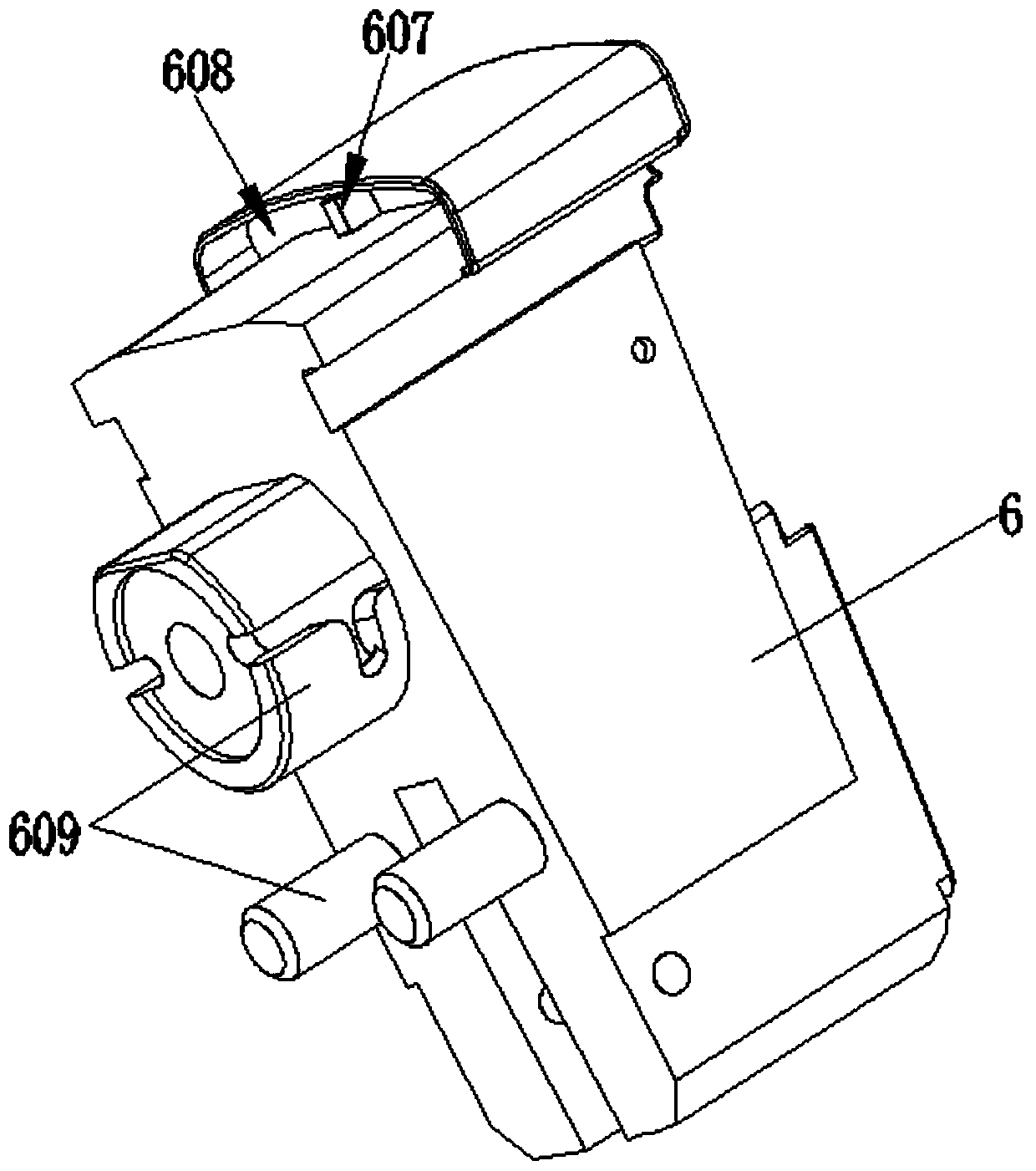

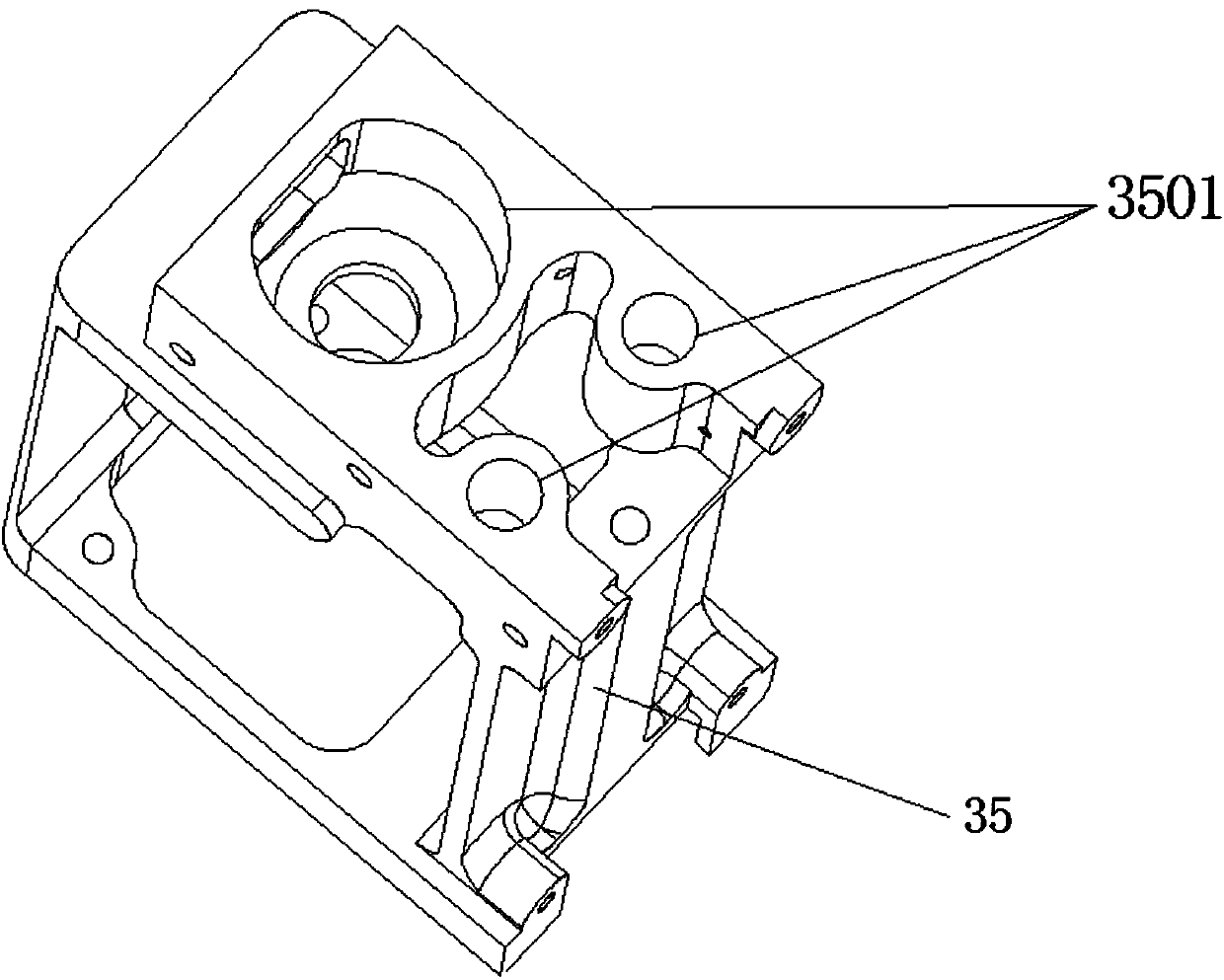

ActiveCN105832161AImprove user experienceImprove experienceBeverage vesselsBiomedical engineeringWater tanks

The invention discloses a hand pressing capsule coffee machine, which comprises a coffee machine body, a capsule carrying casing and a water tank, wherein an installing groove used for accommodating coffee capsules is formed in the capsule carrying casing; a capsule bushing is arranged in the installing groove in a way of surrounding the coffee capsules; a plurality of piercing posts are arranged in the capsule bushing at intervals; a pressure pump assembly is arranged in the water tank; the lower end of the pressure pump assembly is provided with an extruding part; when the capsule carrying casing upwards moves, the coffee capsules ascend, the water inlet ends of the coffee capsules are pierced or broken through by the piercing posts of the capsule bushing. The hand pressing capsule coffee machine has the advantages that in the upward moving process of the capsule carrying casing, the water inlet ends of the coffee capsules are pierced or broken through by the piercing posts of the capsule bushing; simplicity and reliability are realized; the user experience is improved.

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

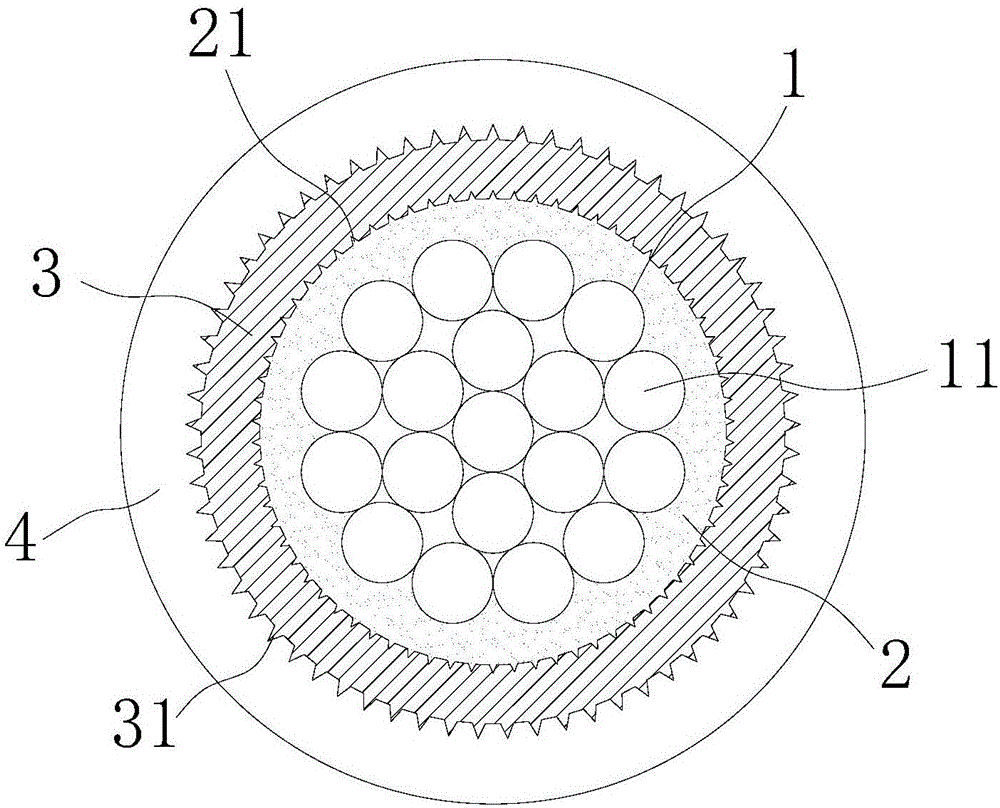

High-insulation cable with high flexibility and easy to bend and fabrication method thereof

ActiveCN106205809AEasy to bendAchieve flame retardant effectFlexible cablesCable/conductor manufactureLow smoke zero halogenElectrical conductor

The invention is applicable for the technical field of a cable, and discloses a high-insulation cable with high flexibility and easy to bend. The high-insulation cable with high flexibility and easy to bend comprises a conductor, a high-insulation layer and a sheath, wherein the sheath comprises a low smoke zero halogen flame-retardant inner layer and a low smoke zero halogen flame-retardant outer layer, second protruding thorns are densely arranged on an external circumferential surface of the low smoke zero halogen flame-retardant inner layer and are internally embedded onto an internal circumferential surface of the low smoke zero halogen flame-retardant outer layer, the conductor is formed by twisting a single conductor line or a plurality of conductor lines and is coated in the high-insulation layer, and first protruding thorns are densely arranged on an external circumferential surface of the high-insulation layer and are internally embedded onto an internal circumferential surface of the low smoke zero halogen flame-retardant inner layer coated at the periphery of the high-insulation layer. The high-insulation cable with high flexibility and easy to bend is reasonable in structure, adjacent layers are highly engaged, the high-insulation cable with high flexibility and easy to bend still has relatively high bending and flexible performance in a low-temperature environment, is long in service life, and has a high insulation effect, and the risk of electric leakage is reduced.

Owner:JIANGSU DONGTENG CABLE TECH CO LTD

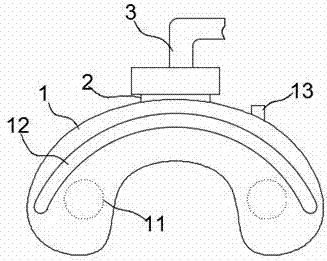

Safe medical mouth gag

InactiveCN107088047AReduce volumeEasy to carryMedical devicesIntravenous devicesSurgeryMedical treatment

The invention relates to a safe medical mouth gag. The safe medical mouth gag comprises elastic occlusion cavities, a clearer and support tubes, wherein an airtight cavity is formed by the support tubes and the occlusion cavities; a liquid storage device is arranged on one occlusion cavity and filled with mutually insulated to-be-reacted drugs; a drug spraying end of the liquid storage device is communicated with the occlusion cavity; the clearer comprises a cylindrical casing, a one-way bearing is mounted on the casing, an outer wheel of the one-way bearing is exposed out of the casing, and a suction wheel is mounted on an inner wheel of the one-way bearing; an elastic telescopic tube is arranged outside the casing, the wall of the elastic telescopic tube is meshed with the outer wheel of the one-way bearing, two ends of the elastic telescopic tube are fixed on occlusion plates respectively, and the occlusion plates are fixedly connected with the occlusion cavities. The safe medical mouth gag is novel and unique in structure, can keep the mouth of a patient open on the premise that teeth of the patient are protected effectively and can effectively prevent a liquid from entering the respiratory tract, and time is gained for medical rescue.

Owner:朱司军

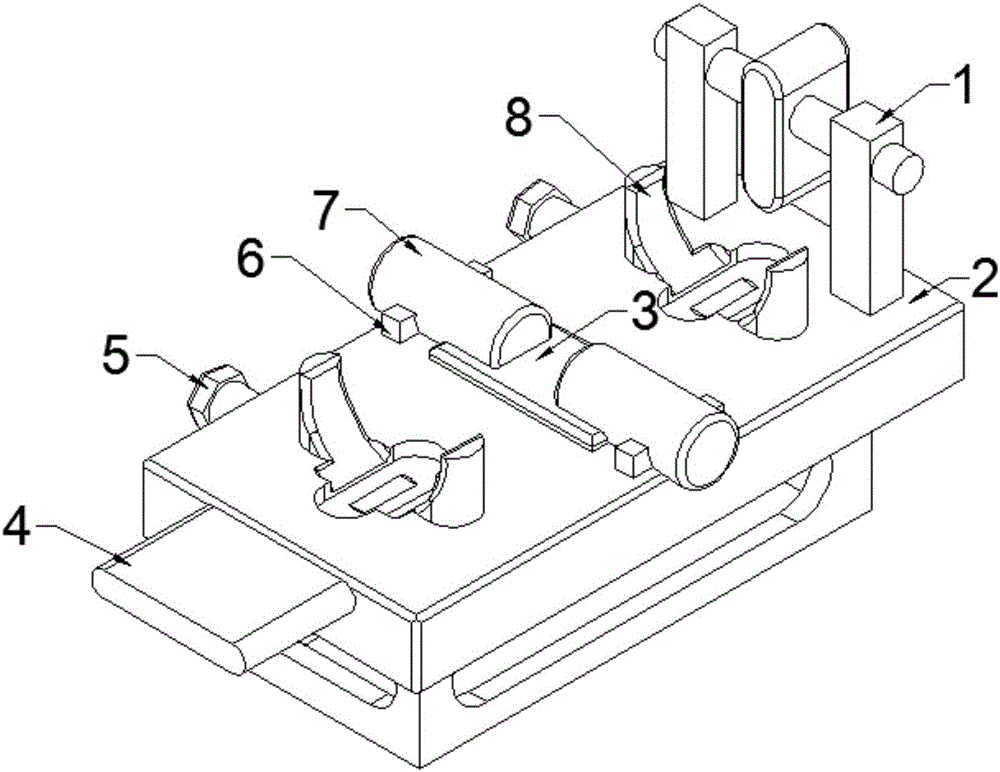

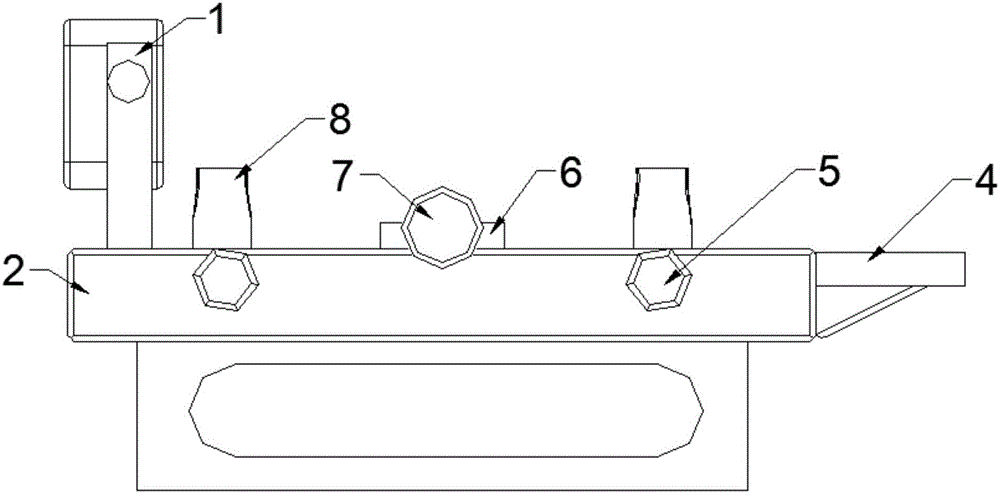

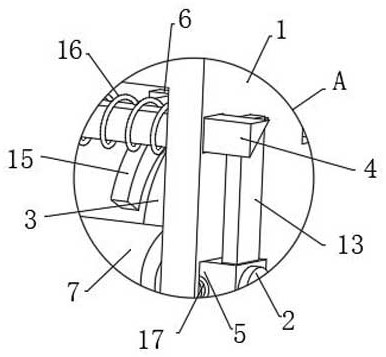

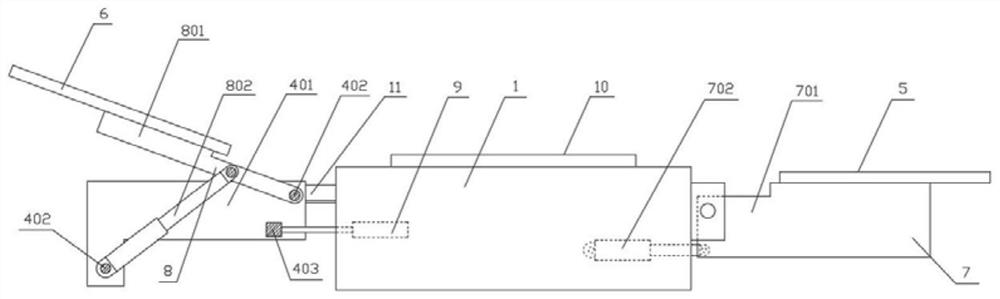

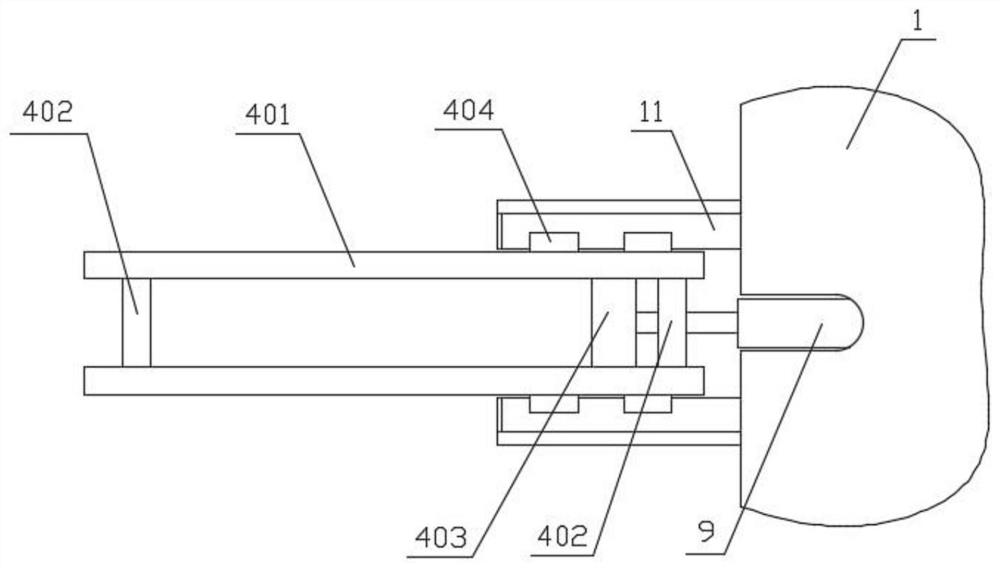

Bicycle steel pipe welding device

InactiveCN106002065AThere will be no misalignmentEasy to align and fixWelding/cutting auxillary devicesAuxillary welding devicesEngineeringPipe welding

This invention provides a bicycle steel pipe welding device comprising a work platform. Position-adjustable positioning blocks are symmetrically arranged on the upper end face of the work platform with the geometric center line of the work platform as a symmetry axis; a cushion plate is arranged at the central position of the work platform; limiting rods capable of sliding on the work platform are arranged on the two sides of the cushion plate; locking pieces used for fixing the positions where the limiting rods are located are arranged in the limiting rods; the arrangement direction of the limiting rods is parallel with the direction in which the positioning blocks are located; a support is arranged on the outer side of the positioning blocks; an ejecting plate used for ejecting out a bicycle steel pipe is rotationally connected to the support; and a collection platform used for collecting the bicycle steel pipe is fixedly connected to the edge of the portion, away from the support, of the work platform. The bicycle steel pipe welding device has the beneficial effects that the positions of the positioning blocks and the limiting rods are adjustable, which provides convenience for a worker to perform alignment of a to-be-welded bicycle steel pipe and makes position alignment operation of the to-be-welded bicycle steel pipe more smooth.

Owner:TIANJIN YOUPENG YONGYUE IND & TRADE

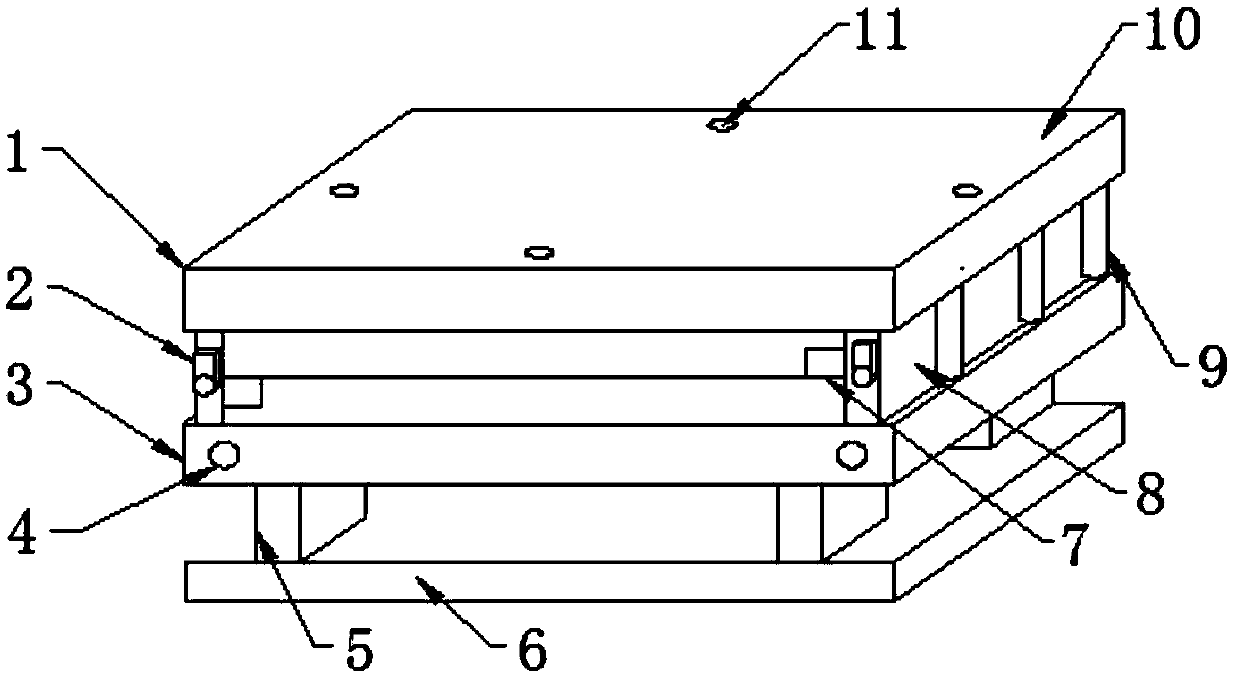

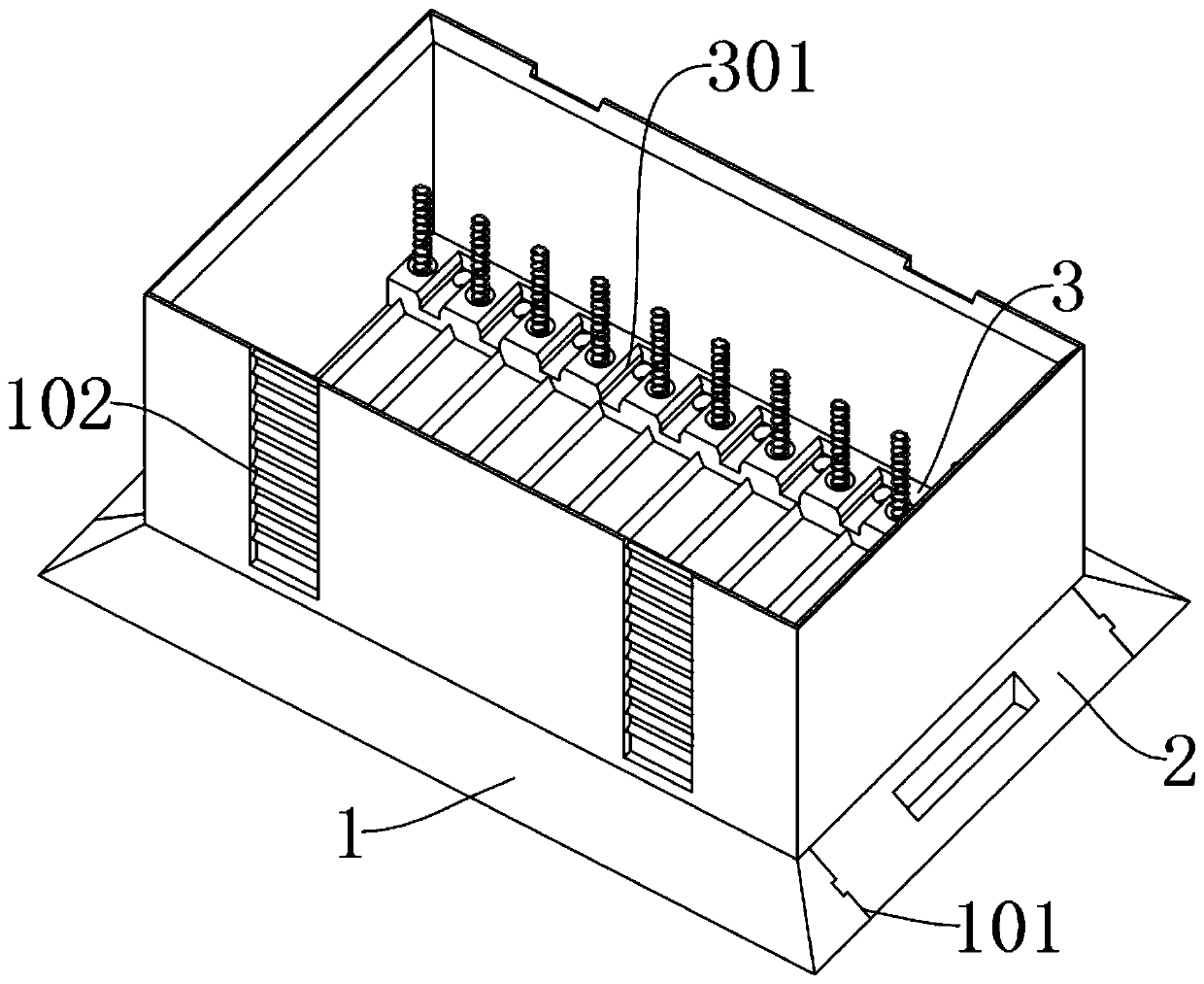

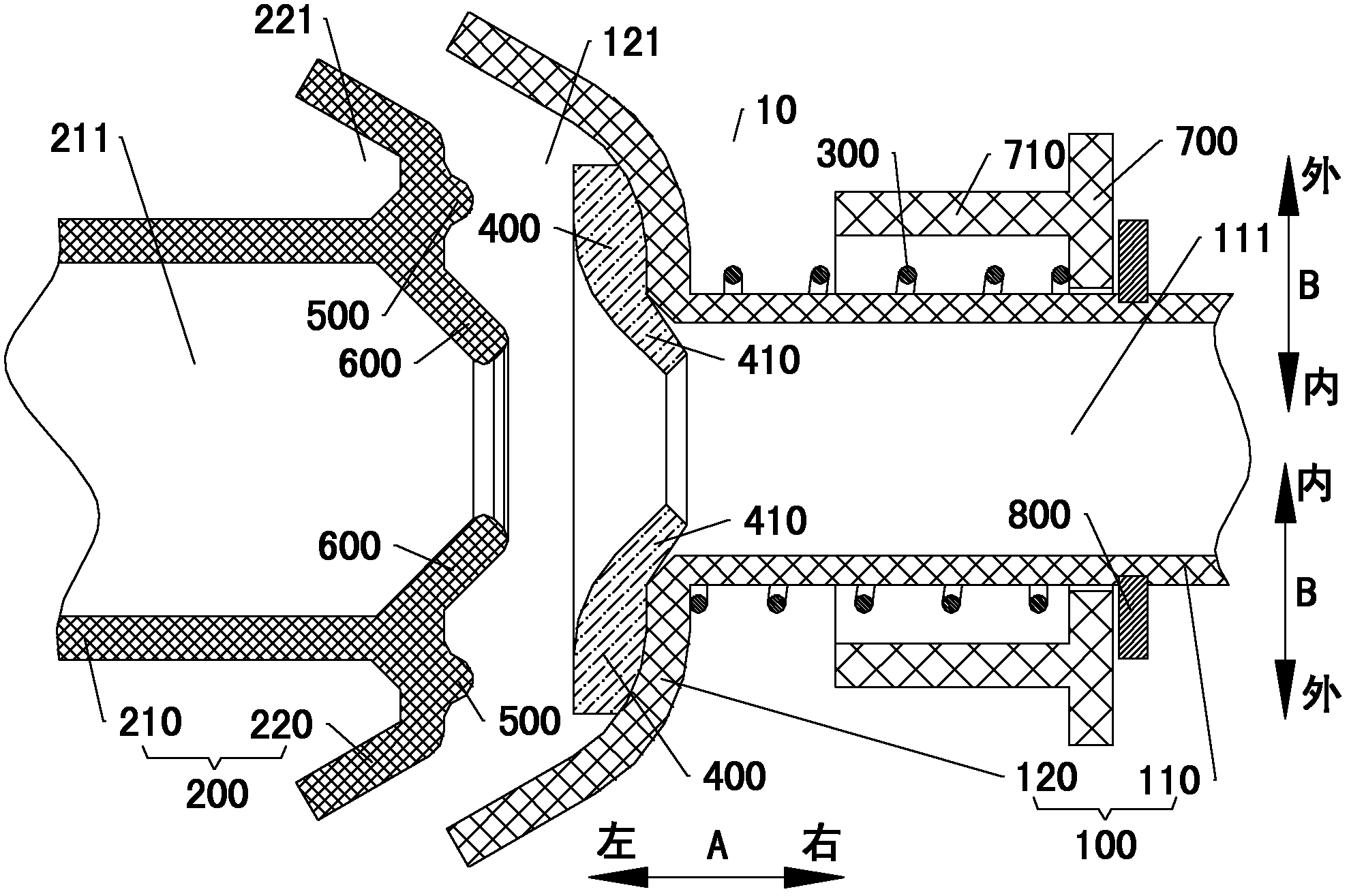

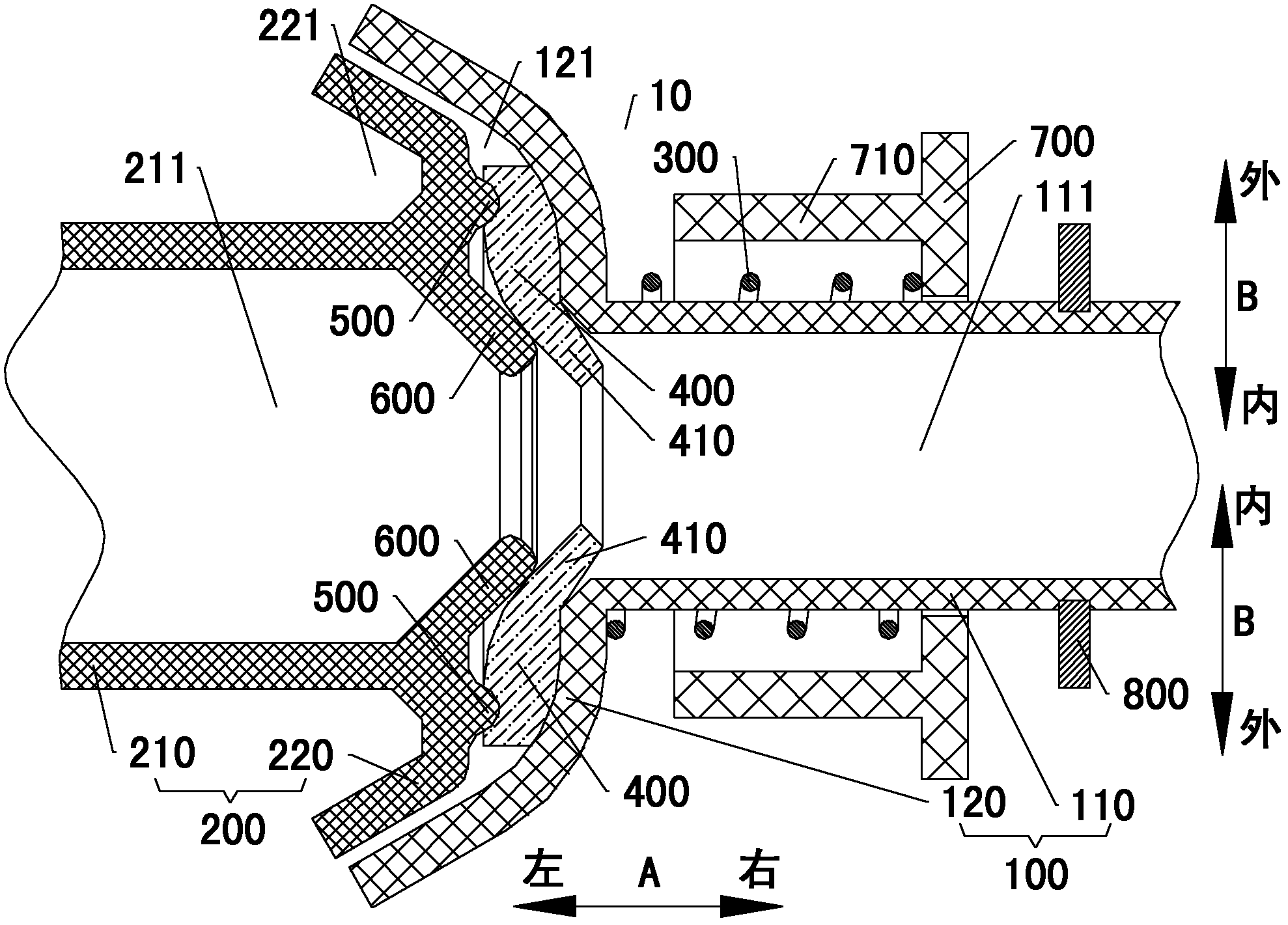

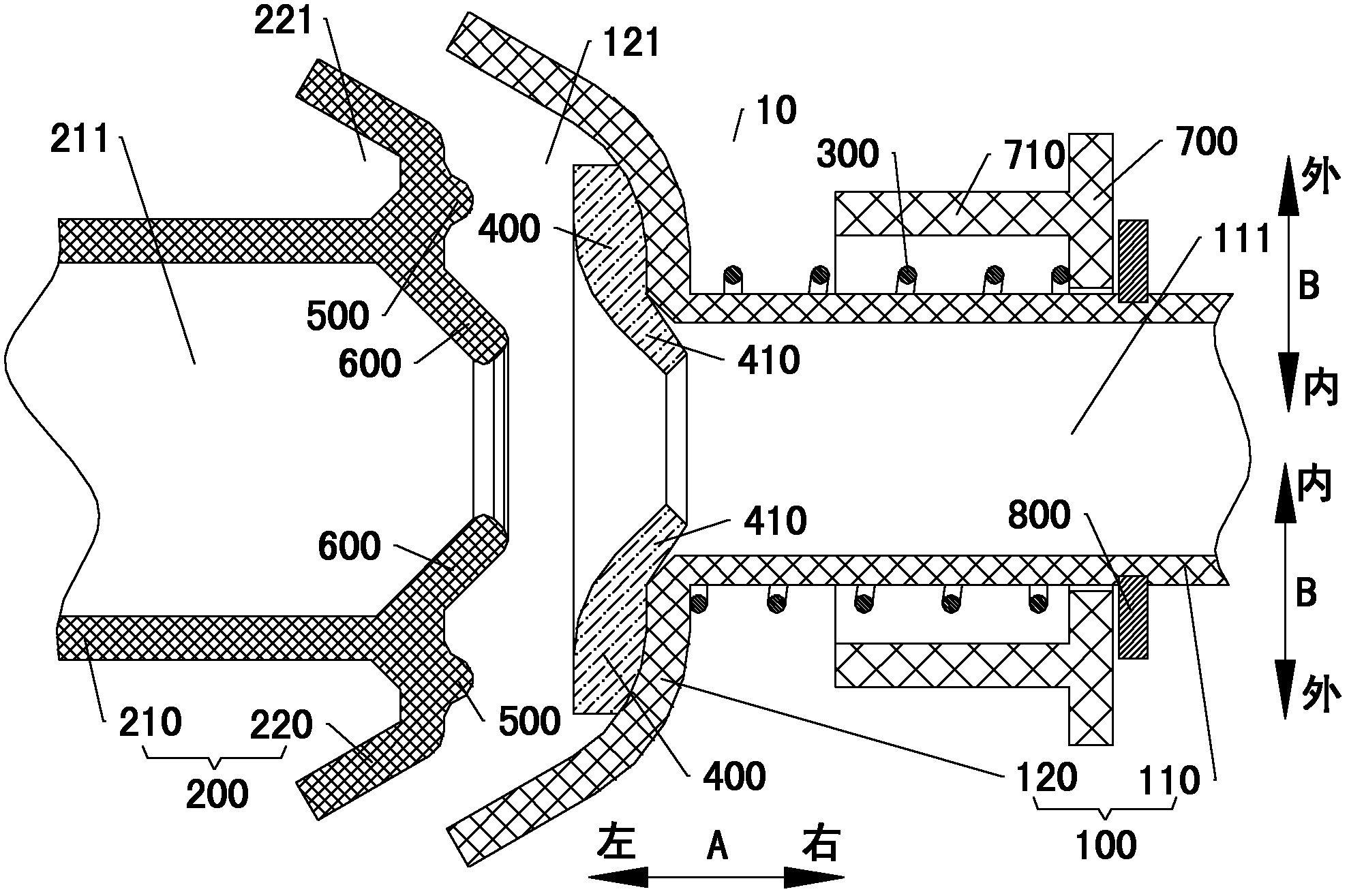

Cooling mould frame for automobile mould

The invention discloses a cooling mold base for automobile moulds, which comprises a mold base main body. The cooling mold base has improved the shortcomings of the original products such as uneven alignment, short service life and insignificant cooling effect. This new type of cooling mold base for automobile molds is equipped with positioning grooves and needle plate guide edges, which realizes For the neat feature, the lower plate and the front panel are first aligned through the positioning groove provided, and then the needle plate guide edge is provided to make the lower plate and the panel align when they are closed, and there will be no misalignment. There is a water delivery hole The cooling effect of the mold base is improved, and the cooling effect is more significant. Using the internal water circulation to cool the mold base can quickly cool the mold base, making the service life of the mold base longer, reducing people's economic losses, and giving People help a lot.

Owner:WUXI SANZHONG MOLD CO LTD

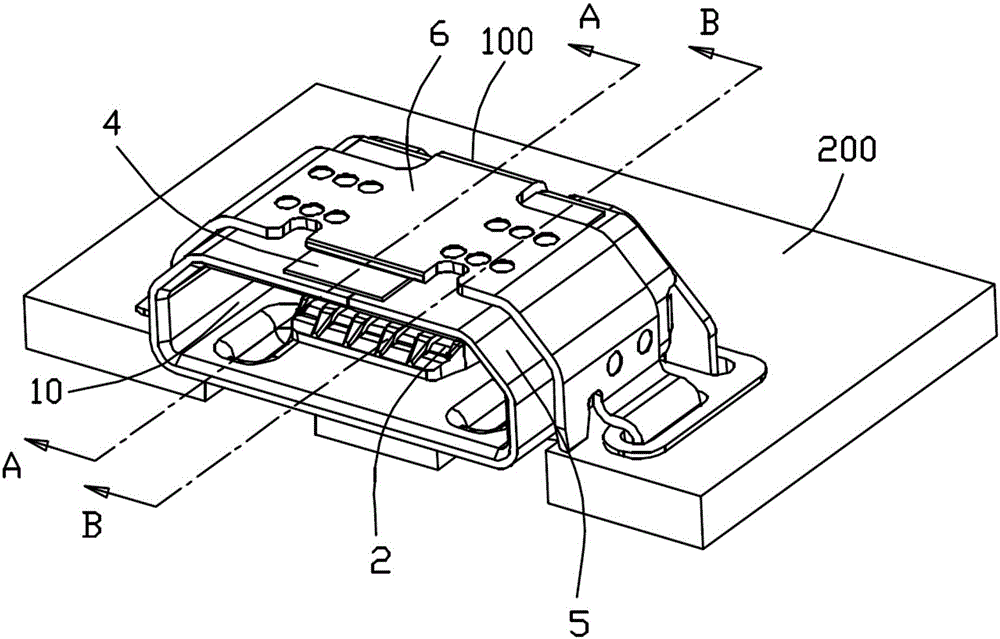

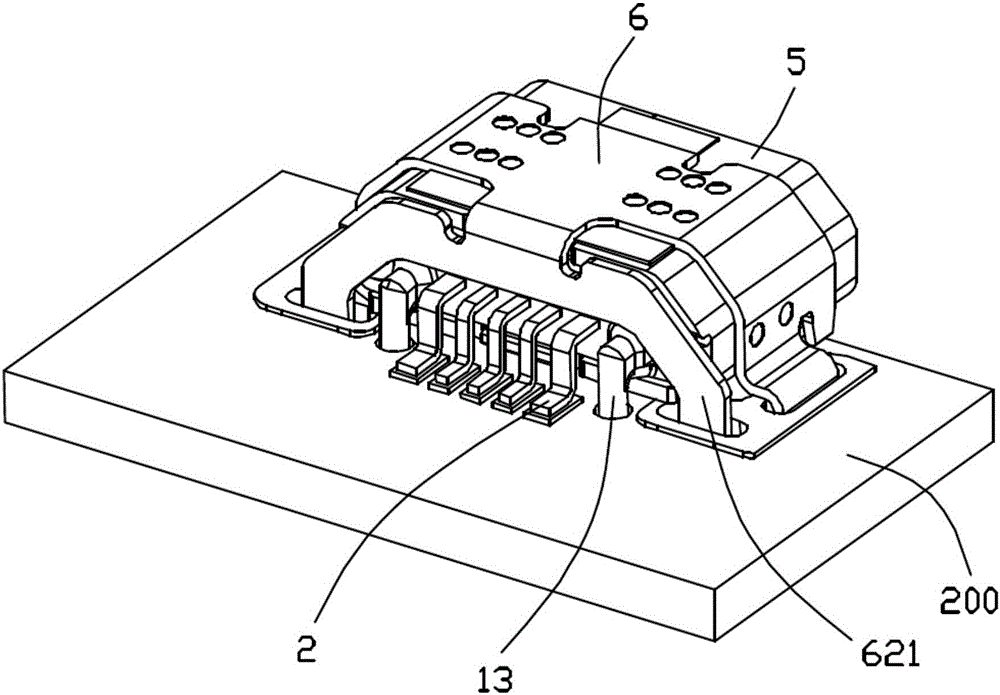

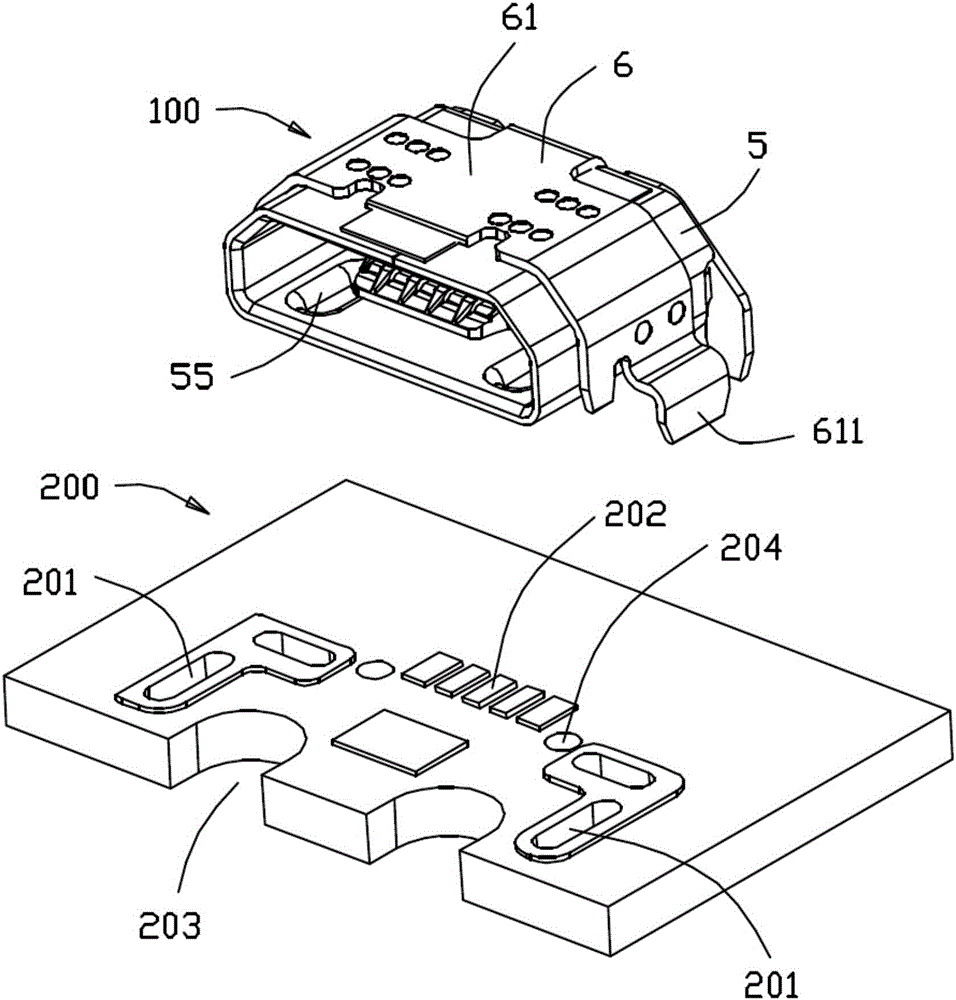

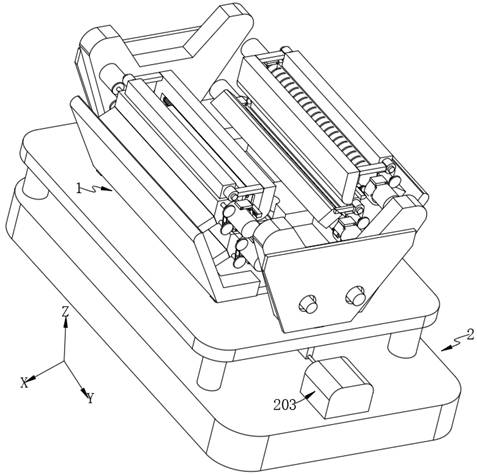

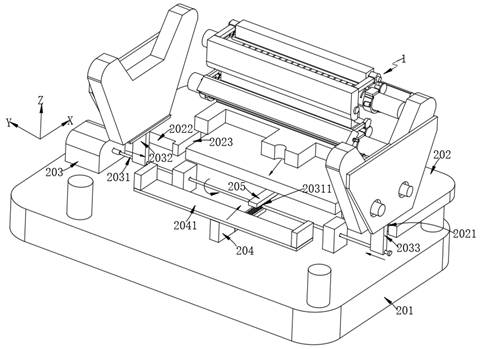

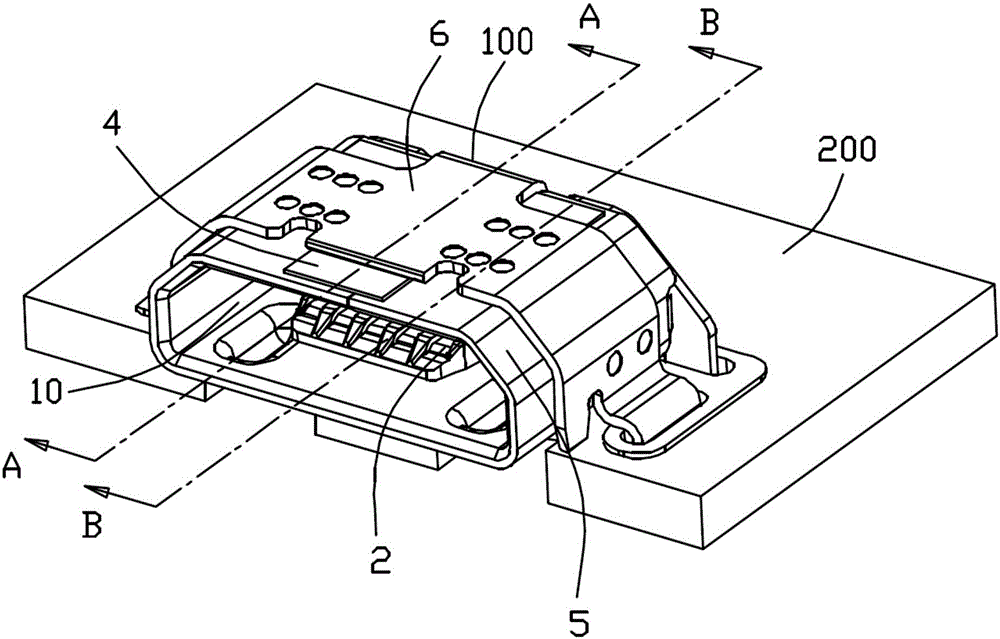

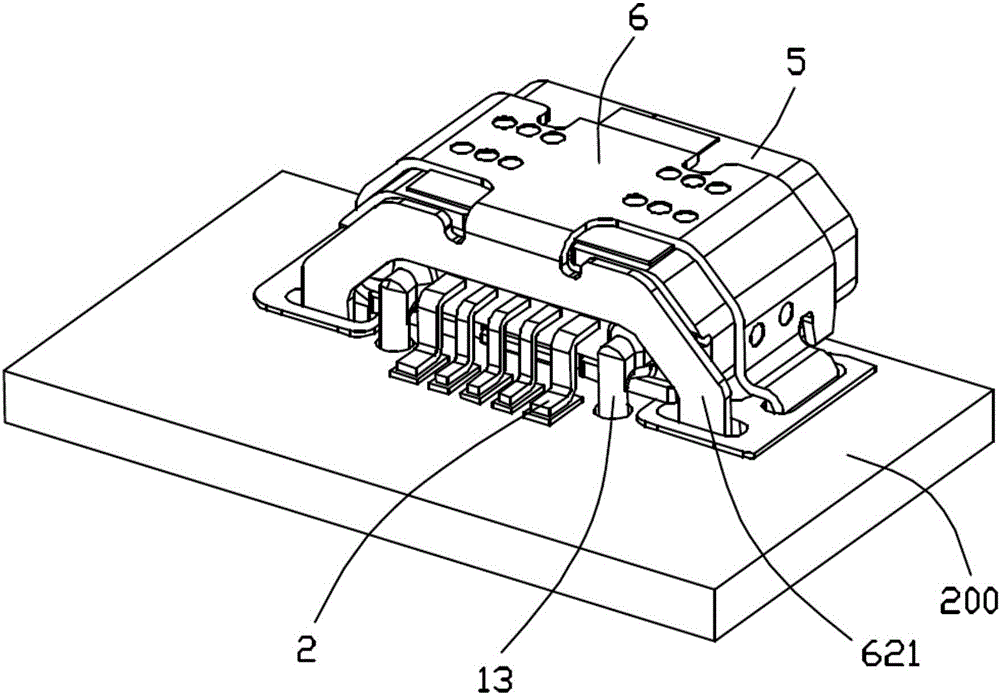

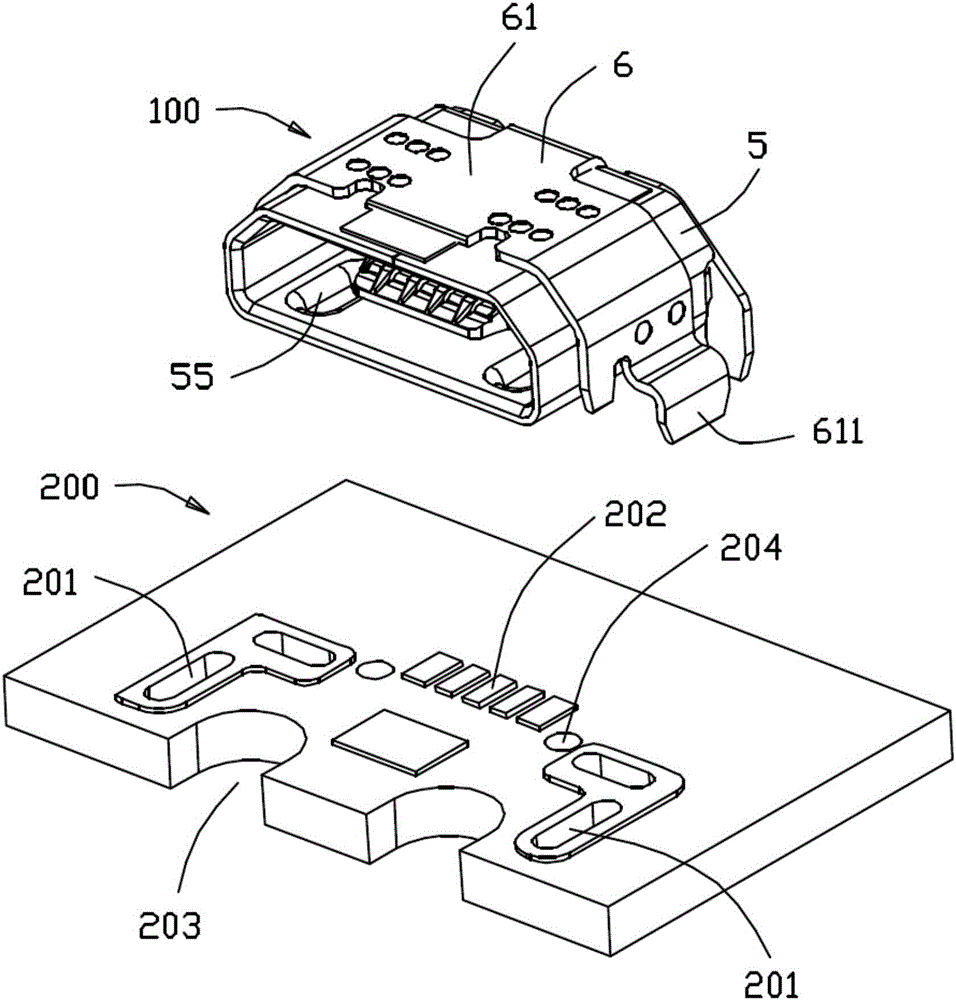

Waterproof micro-usb socket

InactiveCN106785650AThere will be no misalignmentEasy to fillCoupling contact membersCouplings bases/casesCPU socketEngineering

The invention discloses a waterproof micro-usb socket. The waterproof micro-usb socket comprises an insulating body with a base, a plurality of terminals mounted on the insulating body and a shielding shell which accommodates the insulating body and forms an accommodating space; each terminal comprises a contact part which is positioned at the front end of a tongue-shaped plate and is in contact with a butting connector, a welding part which runs through the back end of the base and is bent downwards, and a connecting part which is used for connecting the contact part and the welding part, wherein the waterproof micro-usb socket also comprises a plastic sheet which is laminated on the upper surface of the shielding shell and used for welding and positioning, and a positioning cover which is fixed on the shielding shell through the plastic sheet; the plastic sheet is T-shaped; the waterproof micro-usb socket also comprises a sealing ring; and the sealing ring is accommodated and clamped in a groove to seal a gap between the base and the shielding shell. The plastic sheet is T-shaped, so that the waterproof micro-usb socket is more reasonable in structure.

Owner:池州信安电子科技有限公司

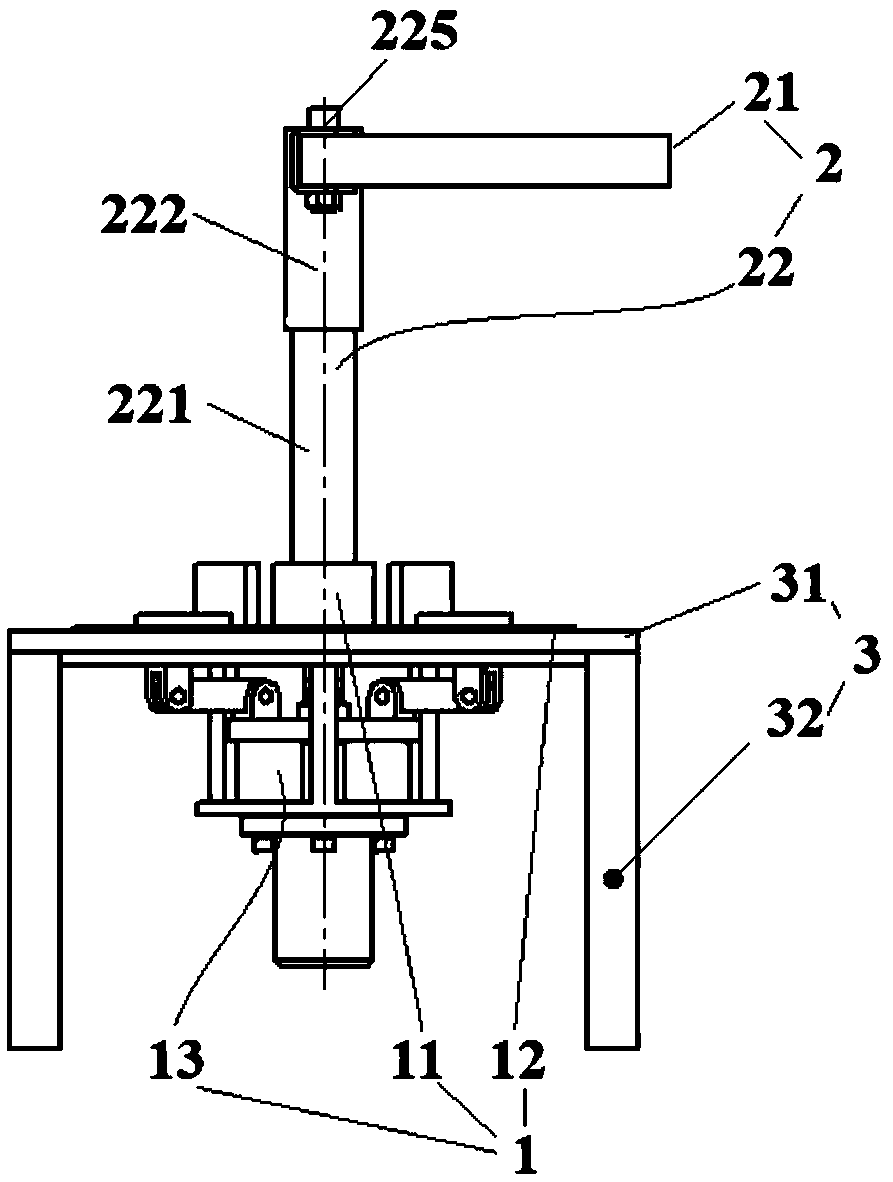

Groove rod insert quartz boat processing equipment

PendingCN114853320ARealize differential movementPrevent dislocationFinal product manufactureGlass reforming apparatusStructural engineeringMechanical engineering

The invention provides groove rod insert quartz boat processing equipment. The groove rod insert quartz boat processing equipment comprises a positioning unit; the assembling unit is arranged at the lower part of the positioning unit; the positioning unit comprises a first positioning assembly; the first positioning assembly comprises a supporting plate; the driving assembly used for driving the quartz groove rod to rotate is arranged in the supporting plate; the clamping assembly used for preliminarily caching the quartz groove rod is rotationally arranged on the side part of the supporting plate; the correction assembly is matched with the clamping assembly and used for orderly aligning and adjusting the orientation of the quartz groove rods and the grooves of the adjacent quartz rods at the same height, and the correction assembly is rotationally arranged on the upper portion of the supporting plate. A pre-tightening spring which is originally in a compressed state drives a main inserting plate to enter a first groove a1 through a telescopic rod, so that a first driving mechanism stops rotating, and it is guaranteed that when quartz groove rods are welded, the matching effect can be kept in the opening direction of the groove rods at the same height.

Owner:HUZHOU OPAL QUARTZ TECH

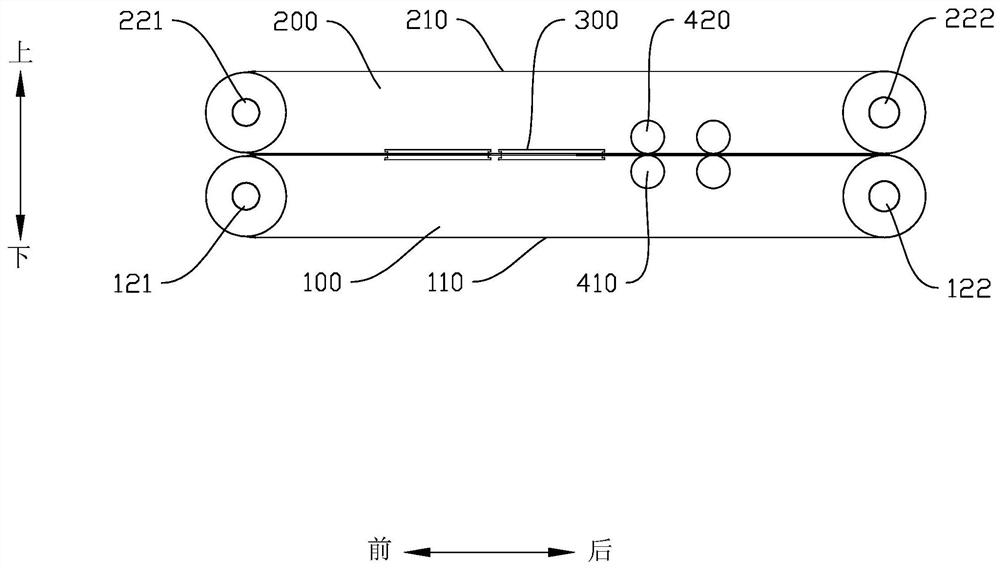

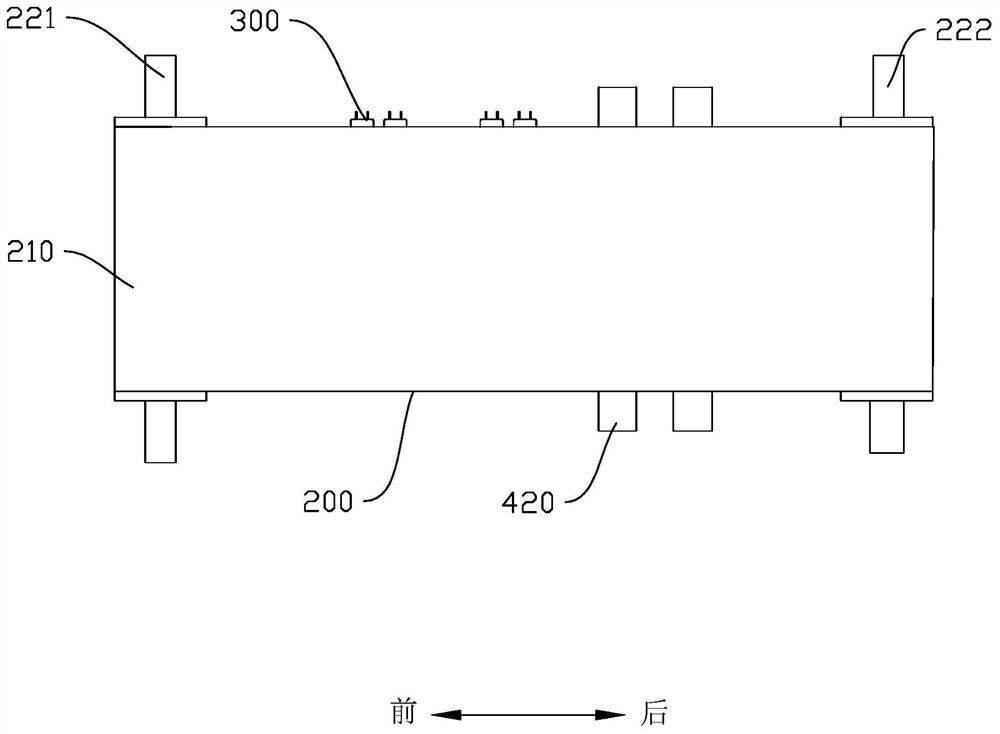

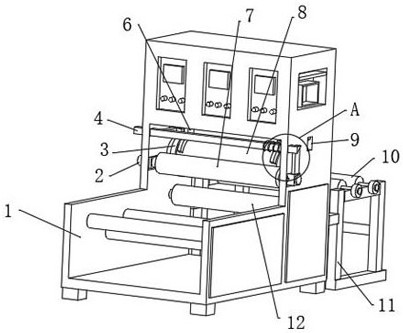

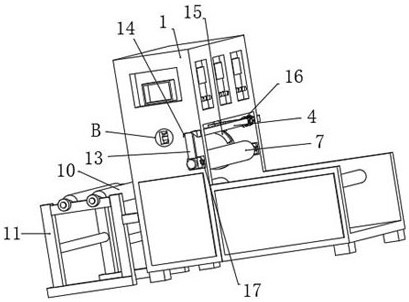

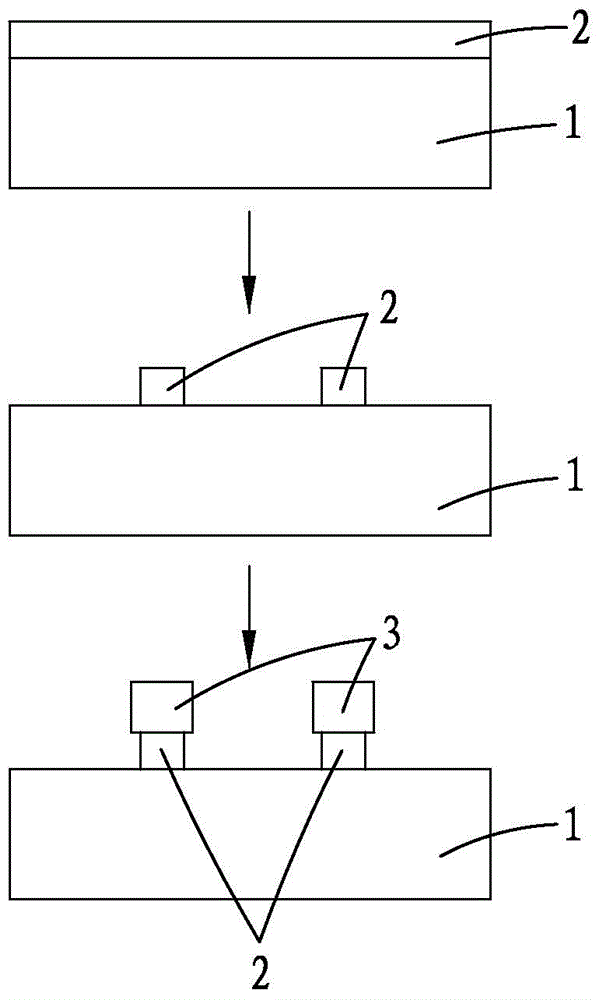

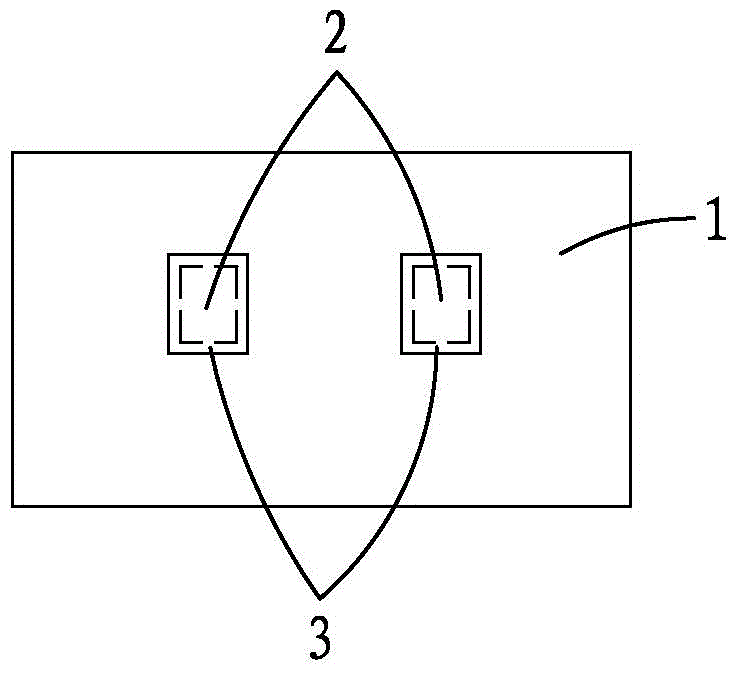

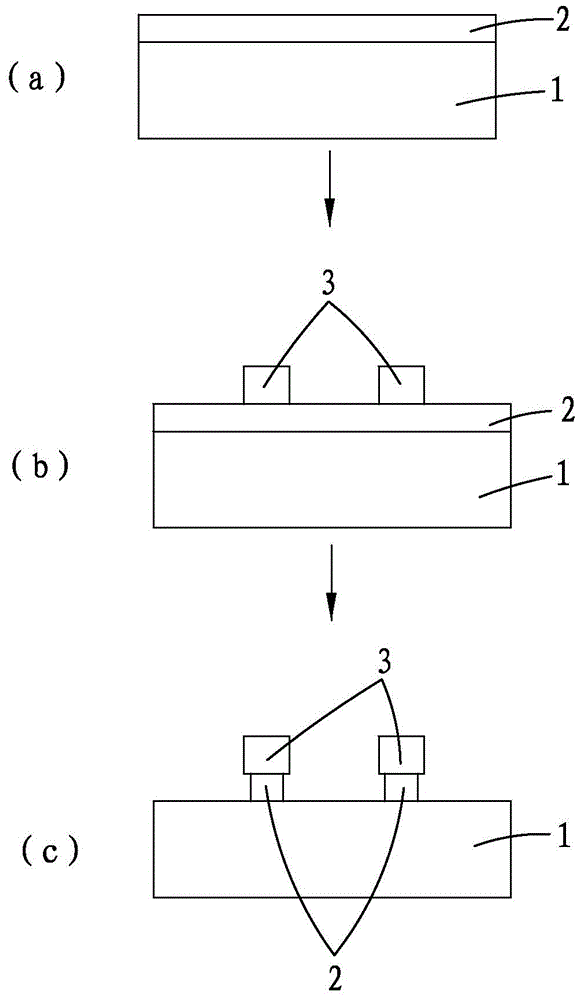

Thermal compounding device and thermal compounding method

PendingCN112123794ASolve the problem of easy frackingImprove warm-up effectFinal product manufactureDomestic articlesPhysicsEngineering

The invention discloses a thermal compounding device and a thermal compounding method. The thermal compounding device comprises a first transmission mechanism, a second transmission mechanism, a heating assembly, force application assemblies and a control mechanism; the first transmission mechanism comprises a first conveying assembly and a first driving assembly, the second transmission mechanismis arranged above the first transmission mechanism in parallel, the second transmission mechanism comprises a second conveying assembly and a second driving assembly, the second transmission mechanism and the first transmission mechanism rotate in opposite directions, a preheating press-fit channel allowing the composite unit to pass through is formed between the second transmission mechanism andthe first transmission mechanism; the heating assembly is used for heating the first conveying assembly and the second conveying assembly; the force application assemblies are arranged on the inner sides of the opposite faces of the first conveying assembly and the second conveying assembly correspondingly; and the control mechanism is electrically connected with the first driving assembly, the second driving assembly, the heating assembly and the force application assemblies correspondingly. According to the thermal compounding device and the thermal compounding method, dislocation and cracking of the composite unit can be avoided, the reject ratio is reduced, and therefore the cost is reduced.

Owner:海目星激光智能装备(江苏)有限公司 +1

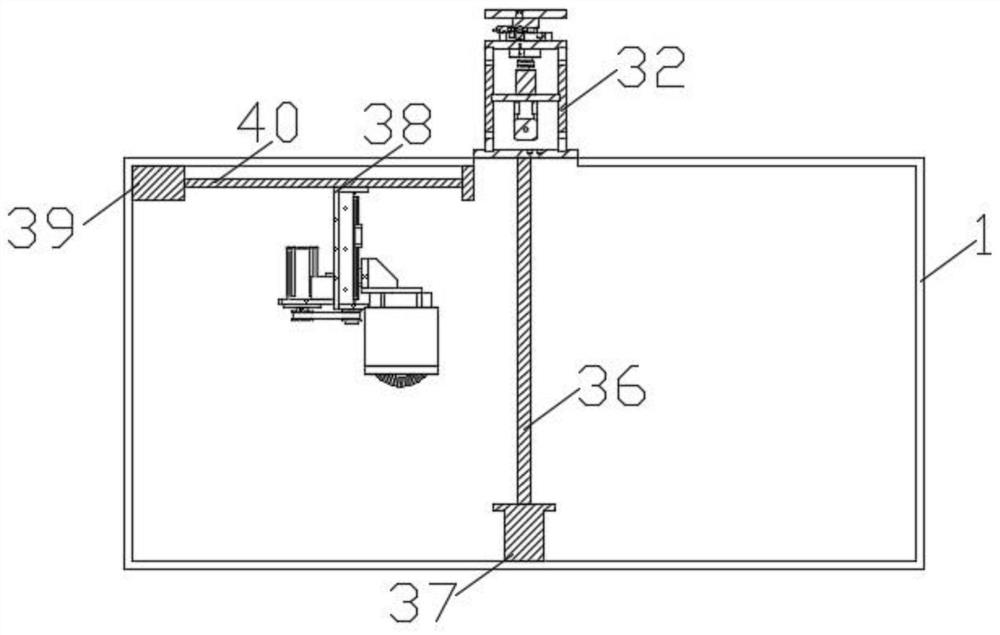

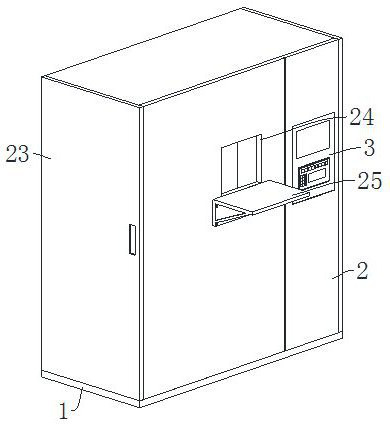

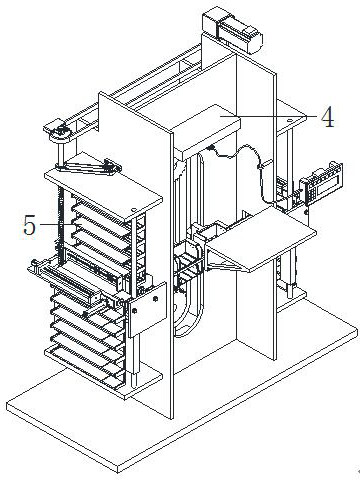

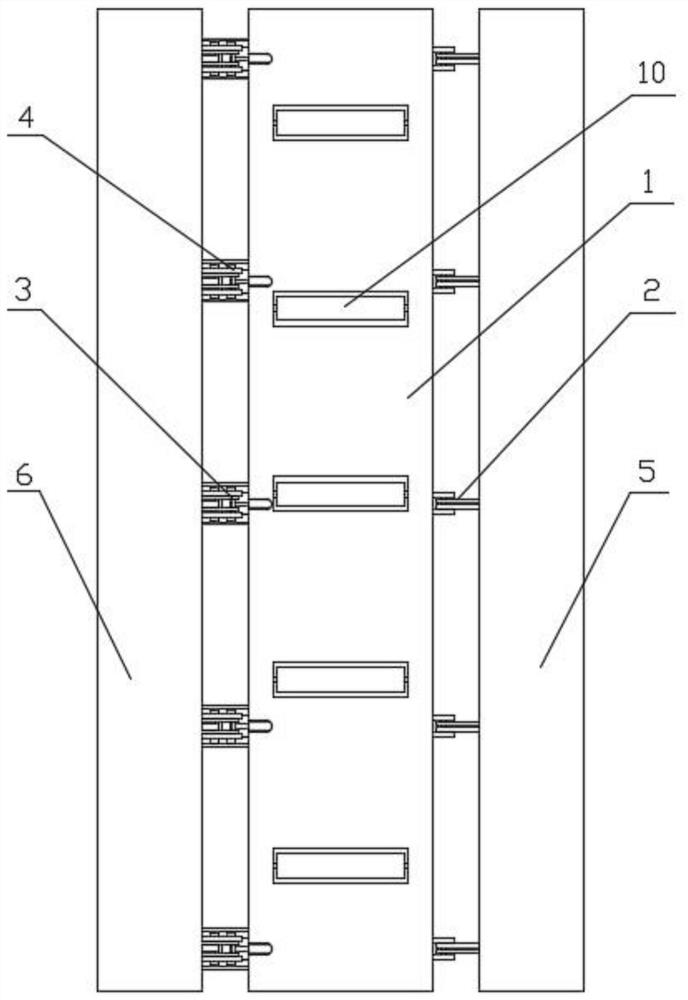

Intelligent extraction system for chronic disease file management

InactiveCN113460545AImprove file extraction efficiencyEasy to storeBook cabinetsStorage devicesEngineeringComputer hardware

The invention relates to the technical field of file management, and specifically relates to an intelligent extraction system for chronic disease file management. The intelligent extraction system comprises a bottom plate, a file cabinet, a control display, an extraction mechanism and two storage mechanisms, the file cabinet is fixedly arranged at the top of the bottom plate, and the control display is fixedly arranged on one side of the file cabinet. The extraction mechanism comprises a rotating assembly, a first induction assembly, two pushing assemblies and two conveying assemblies, each storage mechanism comprises a second induction assembly, a pushing assembly, two sliding assemblies, two slippage assemblies and two pushing and collecting assemblies, and every two corresponding sliding assemblies are fixedly arranged on the side of a corresponding partition plate. The second induction assembly is fixedly arranged on one side of the interior of the file cabinet, and a bearing plate is fixedly arranged at the bottom end of the exterior of a receiving opening. Files stored on each storage plate after category subdivision can be accurately extracted by operating the control display, the intelligent extraction system is rapid, efficient, precise and controllable, and the file extraction efficiency is greatly improved.

Owner:苏春霞

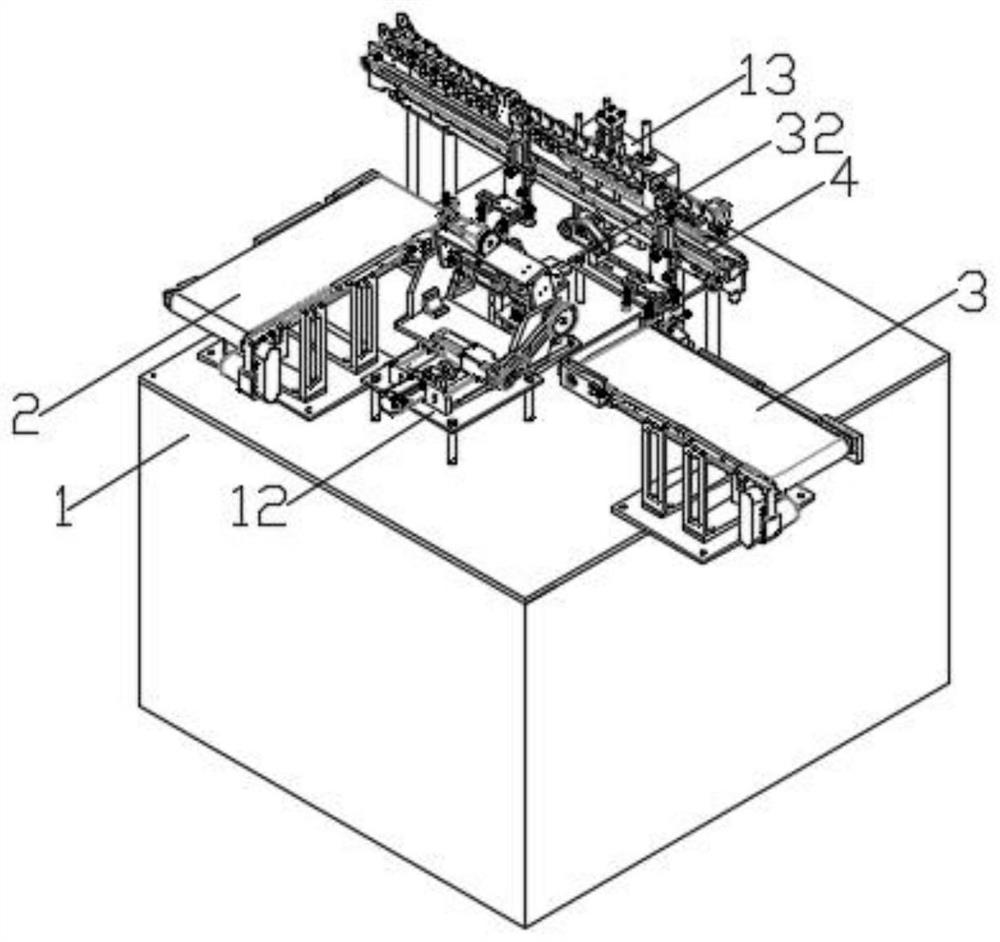

Packaging box manufacturing, forming and processing system

InactiveCN112519311AGuaranteed stabilityThere will be no misalignmentPaper-makingBox making operationsAdhesive glueSlide plate

The invention provides a packaging box manufacturing, forming and processing system. The packaging box manufacturing, forming and processing system comprises a base, two air suction devices, a liftingair cylinder, a lifting plate, an electric sliding block, a U-shaped frame, an erasing device and two sliding plates. The two sliding plates are arranged at the left end and the right end of the base, the air suction device is installed at the upper ends of the sliding plates, and the lifting air cylinder is installed in the middle of the base. The problems that according to a traditional butt joint way, two packaging boxes are usually butted manually, in the butt joint process, due to the fact that glue is in a fluid state and a handheld packaging box is difficult to completely stabilize, when the packaging boxes are attached to each other, the situation that the packaging boxes are misplaced possibly occurs, one-time accurate butt joint is difficult, after butt joint, redundant glue isusually extruded out and left at the butt joint position, and due to the fact that the packaging boxes are prone to slipping after being just butted, when the glue is wiped in multiple directions, thealigned packaging boxes are possibly misplaced again, and the operation is difficult to finish by a single person are solved.

Owner:南京赛逸达自动化技术有限公司

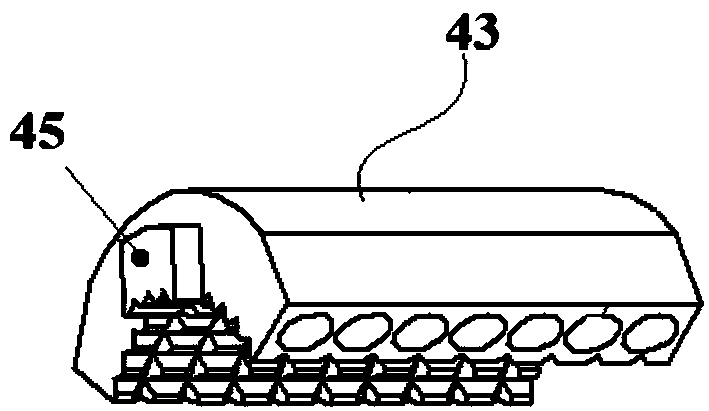

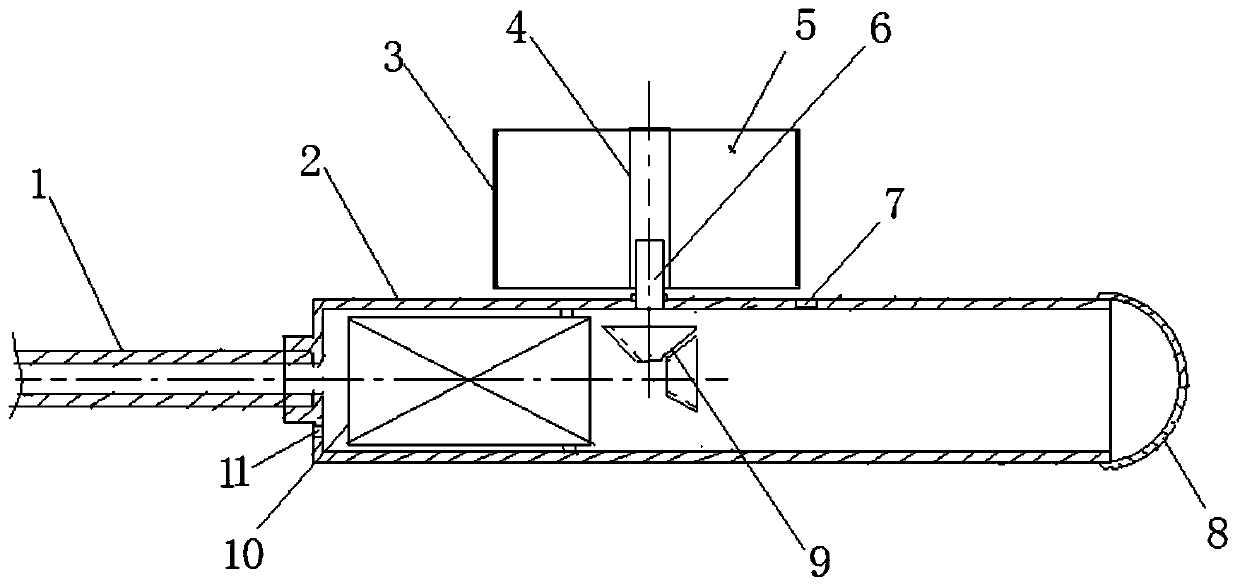

Forepoling bar structure for coal mine excavation

The invention provides a forepoling bar structure for coal mine excavation. The forepoling bar structure comprises a main body, supporting pieces, turning rods, a bearing piece, a clamping piece, moving rods and ejection pieces, wherein the main body is of a rectangular long-strip-shaped structure, moving grooves are formed in the bottoms of the two ends of the main body, each supporting piece comprises connecting plates, and is of a cylindrical structure, an inserting hole of a circular structure is formed in the middle of the bottom of each supporting piece, and the two sides of the bottom of each supporting piece are provided with the corresponding connecting plates. The turning rods are used for being mounted at the bottoms of the supporting pieces so that the forepoling bar structurecan be conveniently and rapidly switched between a moving state and a fixed state when being used, therefore rapid fixing and using can be completed, the turning rods each are of an arc-shaped long-strip-shaped structure so that when the forepoling bar structure needs to be moved through moving wheels, the top ends of the turning rods can be inserted into inserting holes in the bottoms of the supporting pieces, then the turning rods cannot be turned any more, and can be fixed in a using state, and then the forepoling bar structure can be conveniently moved through the moving wheels.

Owner:颜世忠

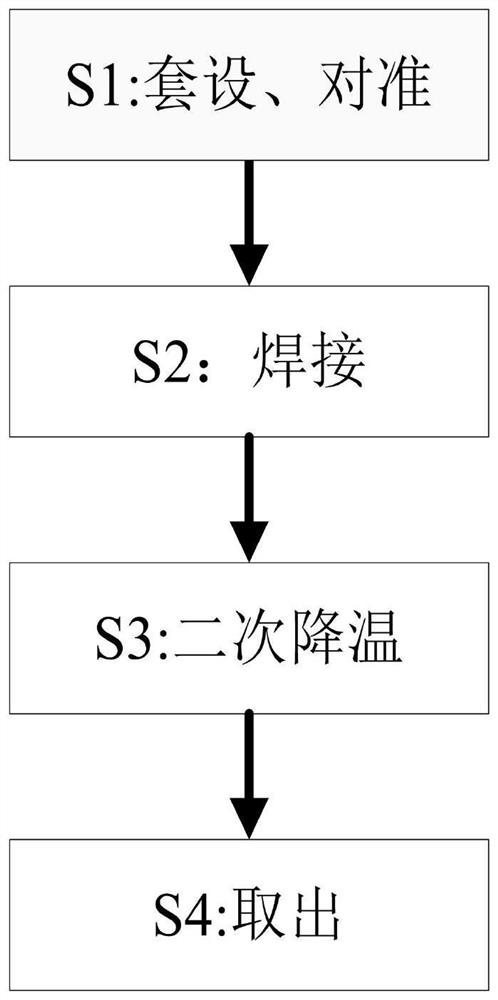

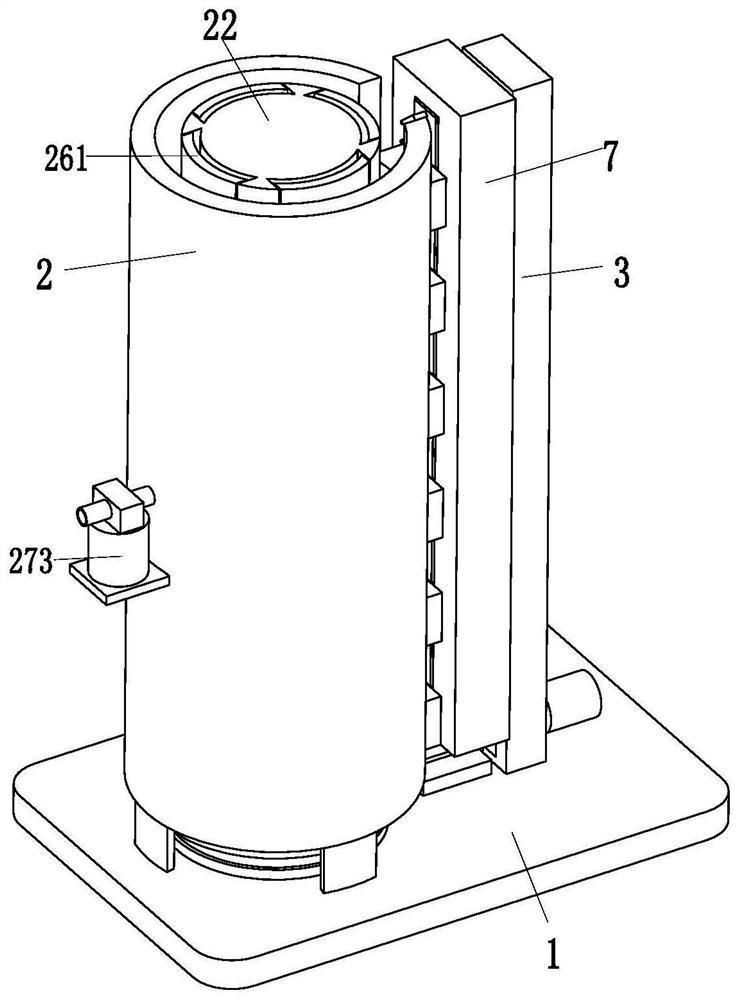

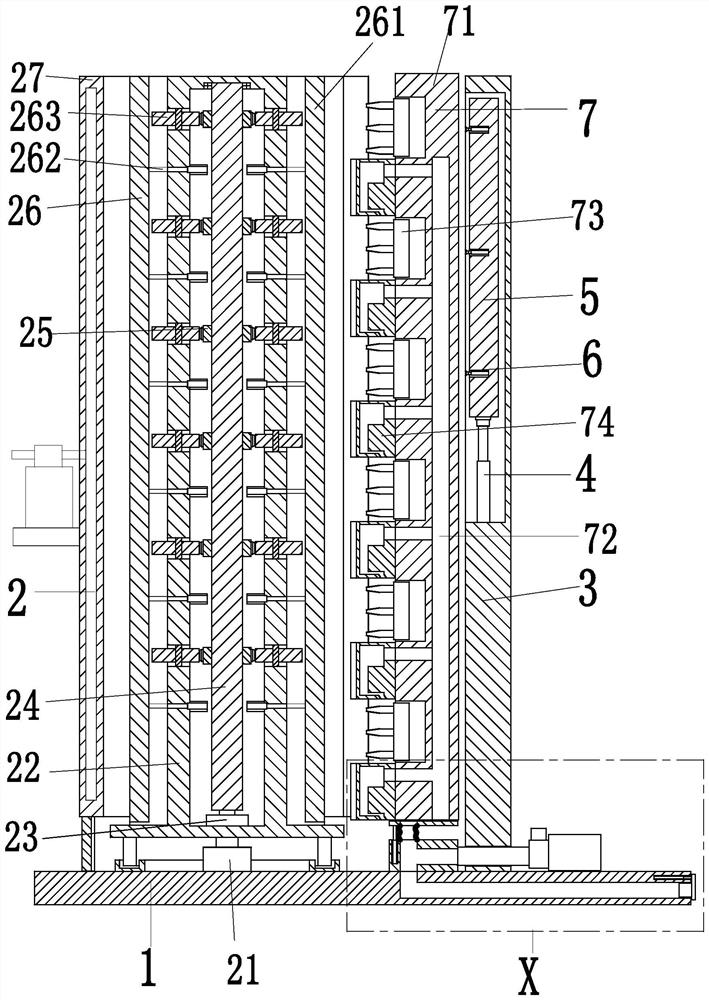

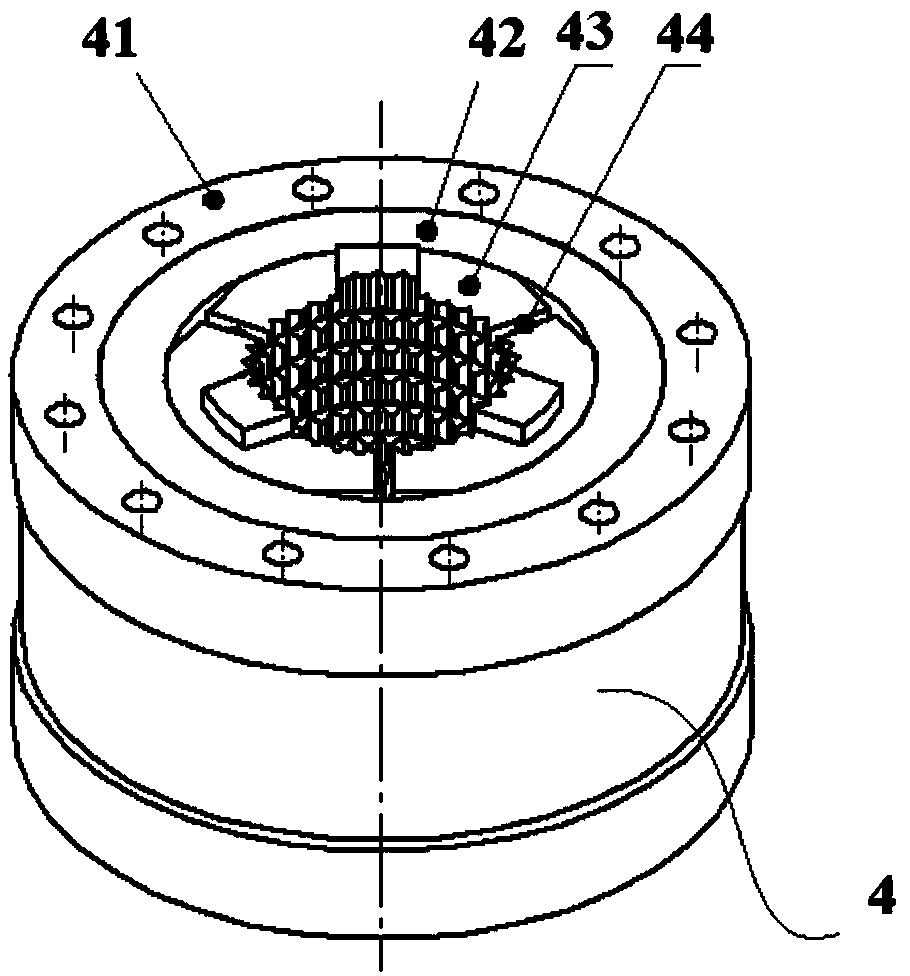

Battery shell manufacturing and processing process

InactiveCN111958140AGuaranteed weldingAvoid indentationCell component detailsWelding apparatusSpot weldingMachining process

The invention provides a battery shell manufacturing and processing process. A bottom plate, a limiting unit, a fixing rod, a lifting air cylinder, a sliding rod, a pushing air cylinder and a spot welding unit cooperate to complete operation. The battery shell manufacturing and processing process can solve the problems that as the thickness of an outer shell is small, a shell is concaved inwards when being clamped by a clamp; lap-joint edge positions are staggered in the clamping process; the condition of leakage welding occurs during electric welding as the lap-joint area of the outer shell is relatively small; the welding position is difficult to rapidly cool down after the battery shell is subjected to spot welding during electric welding; and welding nodules generated after welding aredifficult to timely treat due to the small size, so that the later surface printing process of the battery shell is affected.

Owner:合肥禾松信息科技有限公司

Rubber cylinder hydraulic chuck and slip mounting tool and mounting method

ActiveCN108858043ASimple structureEasy to operateMetal-working hand toolsEngineeringMechanical engineering

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Paper diaper 3D embossing device

ActiveCN113290946ACompound completelyAvoid wastingMechanical working/deformationEngineeringMechanical engineering

The invention discloses a paper diaper 3D embossing device. The paper diaper 3D embossing device comprises a shell, two pressing rollers installed on the shell and two correcting rings, a second embossing roller is arranged between the two pressing rollers, the shell is provided with a first embossing roller used in cooperation with the second embossing roller, the shell is used for supporting the whole paper diaper 3D embossing device, and a rack is installed on the rear side of the shell; and the two correcting rings are symmetrically arranged at the two ends of the second embossing roller, each correcting ring is tightly connected with the shell through a first spring, and a limiting block with the L-shaped cross section is fixedly installed at the top of each correcting ring. A straightening block on an adjusting rod moves and pushes a surface layer at the same time, so that the deviated surface layer is straightened, the subsequent surface layer compounding is more complete, the dislocation phenomenon is avoided, the subsequently produced paper diapers can be normally used, and the resource waste is avoided.

Owner:华昊无纺布(南通)有限公司

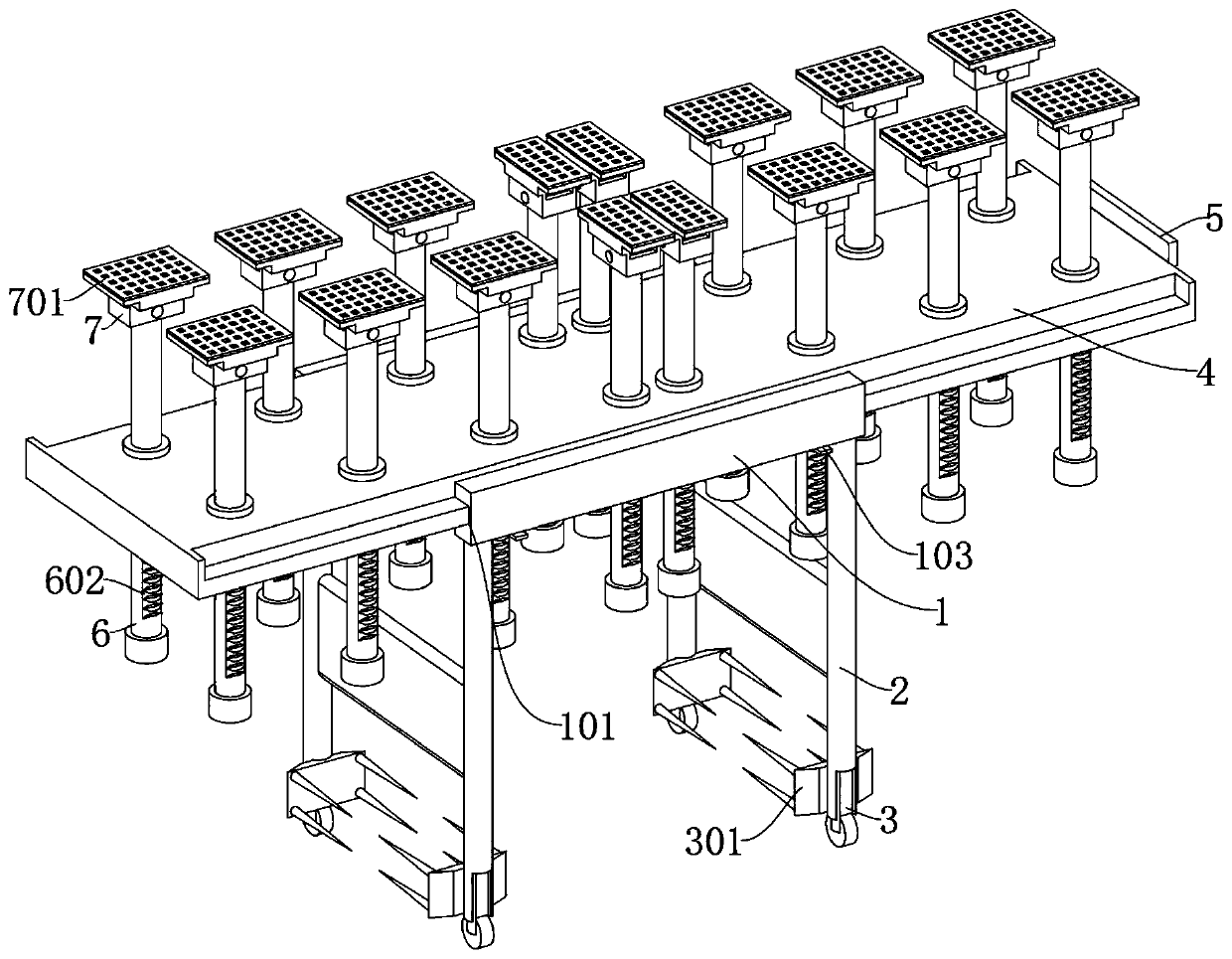

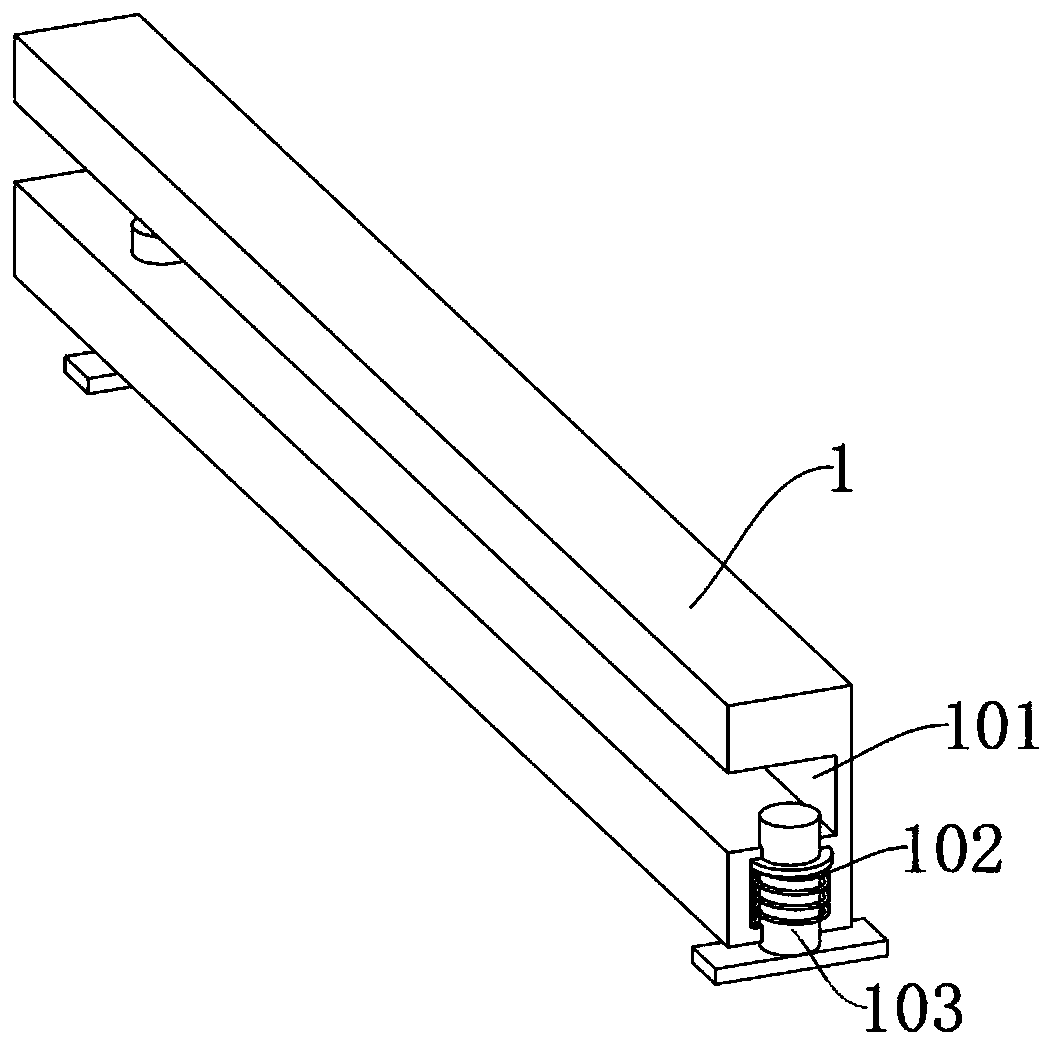

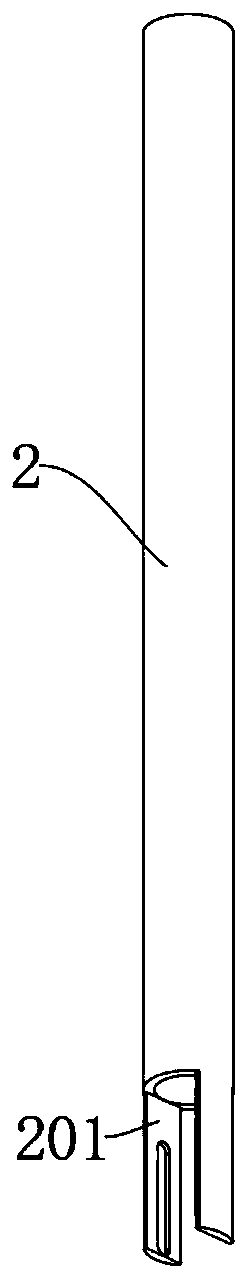

Intelligent mounting system for agricultural vegetable cultivation, and mounting and machining method thereof

ActiveCN108930412AEnsure safetyEasy to operateBuilding material handlingAgricultural engineeringMotherboard

The invention relates to an intelligent mounting system for agricultural vegetable cultivation, and a mounting and machining method thereof. The intelligent mounting system comprises an adjusting device, a main plate, a limiting device, two auxiliary devices, a pressing-stabilizing device and two four-hole pressing plates; and the main plate is mounted at the upper end of the adjusting device, anempty groove is formed in the left side of the front end of the main plate, the limiting device is mounted at the rear end of the main plate, the two four-hole pressing plates are arranged at the leftend of the limiting device and symmetrically arranged, the two auxiliary devices are mounted in the middle of the main plate and symmetrically arranged, and the pressing-stabilizing device is mountedat the front end of the main plate. According to the intelligent mounting system for agricultural vegetable cultivation, and the mounting and machining method thereof, the difficult problems that existing four-hole pressing plates need to be mounted manually, during mounting, personnel need to conduct multiple operations through a climbing ladder, the four-hole pressing plates are not prone to beheld steadily and mounted due to the small size, during manual mounting and clamping of the two four-hole pressing plates, holes between the two four-hole pressing plates are likely to be unaligned,consequently, bolts cannot be screwed into the holes, when the bolts are screwed, manual screwing is not easy can be solved.

Owner:鑫橼(上海)农业科技发展有限公司

Method for printing carbon film plate carbon key

ActiveCN104540329AThere will be no misalignmentAccurate locationConductive pattern formationConductive material chemical/electrolytical removalCarbon filmAcid etching

The invention provides a method for printing a carbon film plate carbon key. A light plate is needed to be provided. The light plate comprises a copper layer on the upper layer and base materials on the lower layer. The method for printing the carbon film plate carbon key comprises the following steps of the step 10 that the carbon key is printed on the light plate and solidified; the step 20 that a circuit is printed; the step 30 that acid etching is performed by etching metal covered by free of the carbon key and metal protected by free of printing ink on the light plate; the step 40 that a character is solder resisted; the step 50 that forming is performed, and factory quality guarantee detection and leaving factory packaging are performed on a carbon film plate finally. Through the method of printing the carbon key firstly and printing the circuit secondly, the method for printing the carbon film plate carbon key avoids a misplacing phenomenon occurring in the positioning process, guarantees the accurate position of every carbon key, and improves the production quality and efficiency greatly.

Owner:福州瑞华印制线路板有限公司

Waterproof mobile phone charging socket

InactiveCN106785649AStable terminal structureGood waterproofCouplings bases/casesTelephony connectorsEngineeringPlastic film

The invention discloses a waterproof mobile phone charging socket which comprises an insulation body provided with a base, a plurality of terminals installed on the insulation body and a shield shell accommodating the insulation body and provided with an accommodating space. The waterproof mobile phone charging socket further comprises a plastic sheet attached to the upper surface of the shield shell and used for welding and positioning, a positioning cover fixed to the shield shell through the plastic sheet and a sealing ring, and the sealing ring is accommodated and clamped in a groove to seal gaps between the base and the shield shell. By the arrangement of the plastic sheet, the positioning cover can be fixed to the shield shell.

Owner:池州信安电子科技有限公司

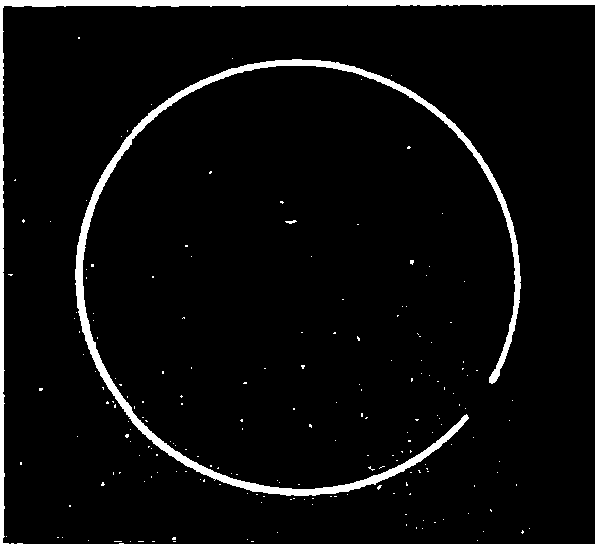

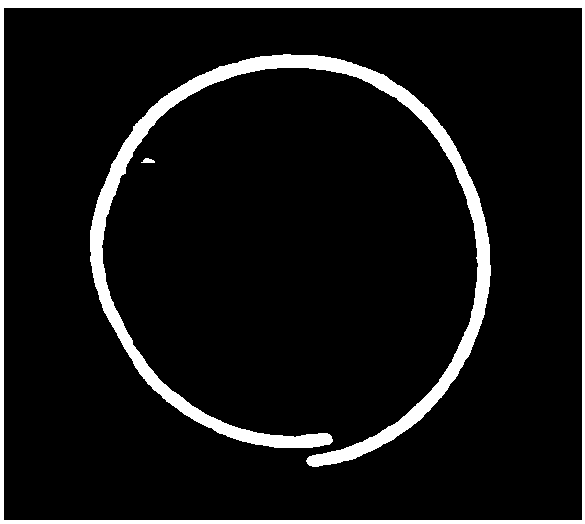

Cutting and marking effect optimization method for arc-shaped butt joint of laser equipment

The invention provides a cutting and marking effect optimization method for an arc-shaped butt joint of laser equipment. The method comprises the following steps of 1, preset; 2, positioning; 3, operation; 4, optimization; and 5, circulation. In the step 1, a required arc shape or circle is drawn in advance in a control system; in the step 2, a scanning head is moved, so that the working focal length of a laser is enabled to correspond to the starting point position; in the step 3, the laser is started, a working light source is generated, and the working light source is cut and marked according to the shape pre-drawn in the step 1; in the step 4, the arc-shaped or circular marking is started from a starting point position, and then the laser is turned off at the terminal position, so thatthe scanning head continues to go away for a certain distance under the state that the laser is close to the working light source, and an optimized position is reached; and in the step 5, after the scanning head is moved away for a certain distance, the scanning head continuously moves to the position of the starting point of the next arc or the arc according to the continuous cutting and markinginstructions sent by the control system, and the next cycle is carried out. The problems that when the laser is used for cutting or marking the arc, seals cannot be closed, and are tilted or overlapped are solved.

Owner:GUANGZHOU NEW CKLASER CO LTD

Crane main beam box splicing and assembling device

PendingCN112743280AGuideAct as a limitWelding/cutting auxillary devicesAuxillary welding devicesClassical mechanicsEngineering

The invention discloses a crane main beam box splicing and assembling device which comprises a placing table, a first clamping device, a second clamping device and a moving platform, the first clamping device is mounted on one side of the placing table, the moving platform is mounted on the other side of the placing table, the second clamping device is mounted on the moving platform, and the first clamping device comprises a first supporting plate and a first driving mechanism capable of overturning the first supporting plate from the horizontal state to the vertical state; and a horizontal oil cylinder for driving the moving platform to be far away from or close to the placing table is mounted between the placing table and the moving platform, the second clamping device comprises a second supporting plate and a second driving mechanism for overturning the second supporting plate from the horizontal state to the vertical state. The crane main beam box splicing and assembling device is used for solving the problem in the prior art that the welding quality of a beam box of a crane main beam is not stable because the placing position of the beam box is not accurate and the beam box cannot be tightly attached to the two sides of a partition plate all the time in the welding process in the assembling and welding process of the beam box of the crane main beam.

Owner:HENAN HENGYUAN HENGSHAN IND CO LTD

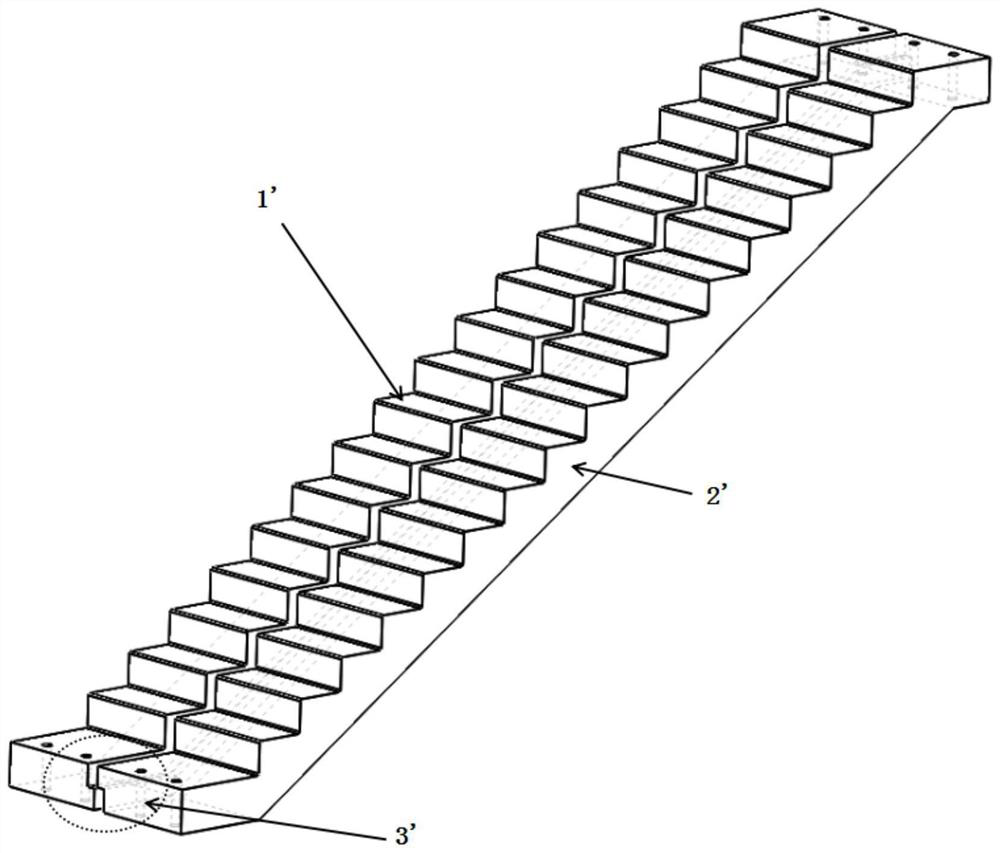

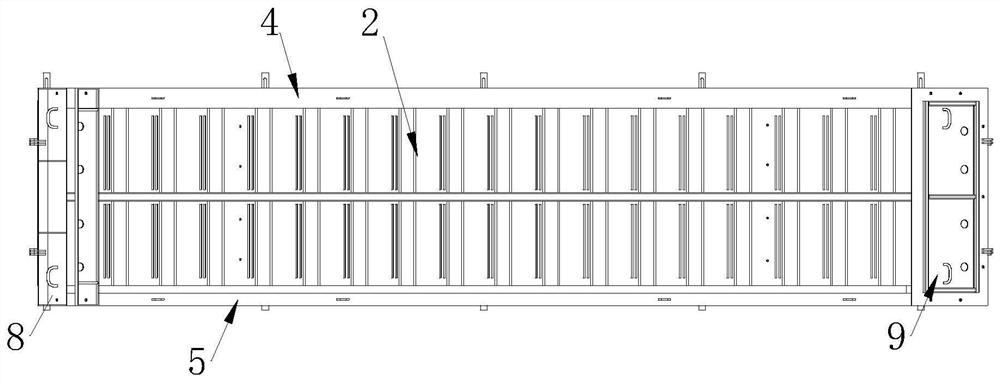

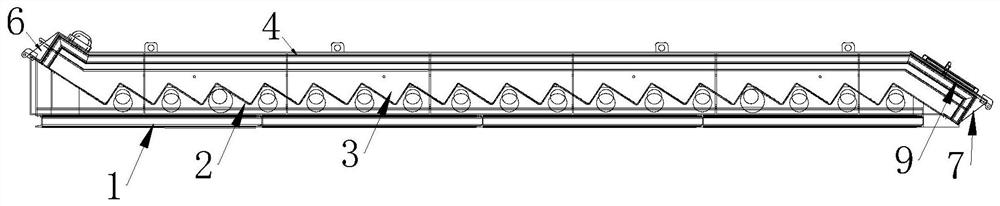

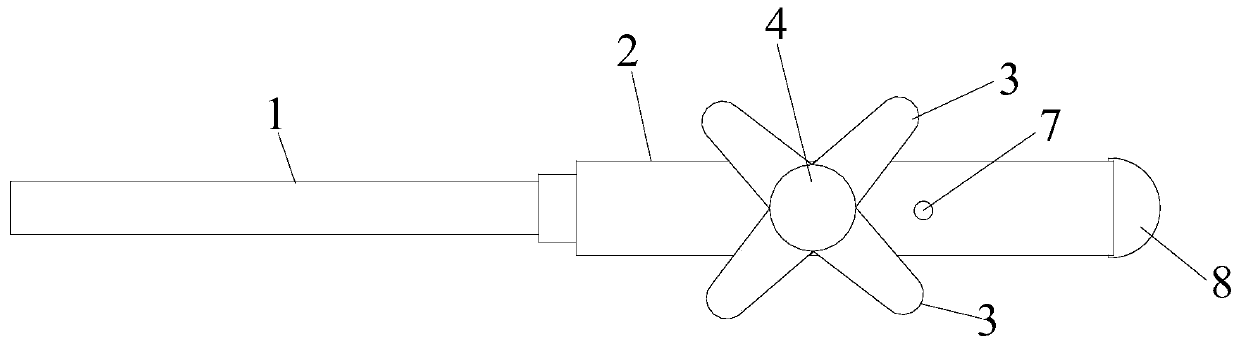

Split type prefabricated stair integrated forming die and stair production method

The invention relates to a prefabricated building, in particular to a split type prefabricated stair integrated forming die and a stair production method. A partition plate is arranged in the middle of a step forming face of the die, a first side flange is arranged on one side of the step forming face, a second side flange is arranged on the other side of the step forming face, a female tongue-and-groove forming boss is arranged on the upper portion of the inner side of the first side flange, a male tongue-and-groove forming concave portion is arranged on the lower portion of the inner side ofthe second side flange, a left sub-stair and a right sub-stair of a split type stair can be formed in the same die in a one-time pouring and tamping manner, and therefore the die cost of the prefabricated stair is reduced, the production efficiency is improved, and step dislocation generated when the left sub-stair and the right sub-stair are spliced is avoided.

Owner:XIANGTAN YUANDA RESIDENTIAL IND CO LTD

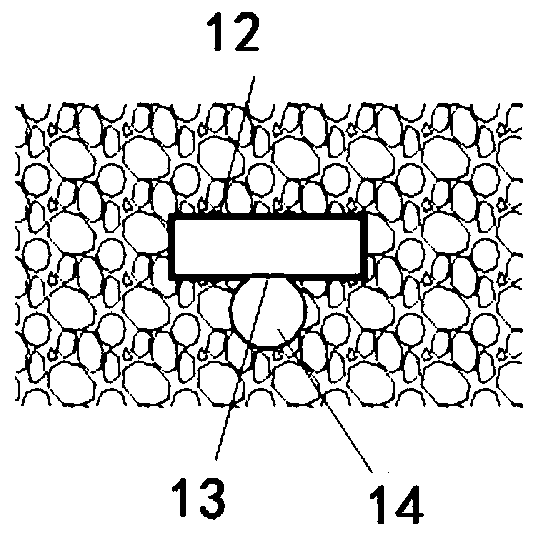

Rectangular drilling device based on fan-shaped drill bit and drilling method

PendingCN110242211AEffective installationPrevention and Control of Power DisastersDrilling rodsConstructionsStress monitoringDrilling machines

The invention discloses a rectangular drilling device based on a fan-shaped drill bit and a drilling method. The rectangular drilling device based on the fan-shaped drill bit comprises a hollow drill rod and a drill bit, and the hollow drill rod is formed by fixedly connecting a guide drill rod and a connection drill rod and used for carrying drill bit to drill by linear advance; the connection drill rod is used as a connection rod between the guide drill rod and a drilling machine, the guide drill rod plays the fixing guide effect, and it is ensured that the fan-shaped drill bit cannot drill obliquely in the drilling process; and the drill bit is arranged on the outer side wall of the guide drill rod, the drill bit realizes rotation depending on power of a motor arranged in the guide drill rod, and the shape of the drill bit guarantees that a rectangular drill hole can be drilled in the rotating process of the drill bit. According to the rectangular drilling device based on the fan-shaped drill bit and the drilling method, the rectangular drill hole can be drilled, a rectangular stress monitoring device can be effectively installed, a basis can be laid for monitoring an accurate stress evolution law, and important significance is achieved for preventing and controlling mine dynamic disaster.

Owner:XINWEN MINING GROUP

Pressing auxiliary punching device based on automobile carbon fiber part machining

The invention provides a pressing auxiliary punching device based on automobile carbon fiber part machining. The pressing auxiliary punching device comprises a body, a bottom part, limiting parts, a moving part, an ejecting part, rotating parts and a punching head. The body is of a rectangular structure, and the two sides of the bottom of the body are of inclined structures. The bottom part is installed in an installation groove in the bottom of the body, and guide blocks on the two sides of the bottom part are embedded and installed in embedded grooves. The limiting parts are installed at theinner bottom end of the body in a fixed connection manner, and the limiting parts are used for being arranged at the inner bottom end of the body so that when the ejecting part makes contact with themoving part to conduct primary punching forming on carbon fiber parts, the ejecting part can be used for downwards ejecting the moving part continuously. Thus, the bottom of the moving part can makecontact with the limiting parts again, the carbon fiber parts can be punched and pressed again, after the parts are formed, the surfaces can be more smooth, and insertion grooves are used for clampingblocks at the bottom of the moving part to be embedded.

Owner:湖北衍驰科技有限责任公司

Joint assembly for water pipe and water pipe and refrigerator with joint assembly

ActiveCN102628534AAccurate connectionQuick connectionLighting and heating apparatusDomestic refrigeratorsEngineeringRefrigerated temperature

The invention discloses a joint assembly for a water pipe and a water pipe and a refrigerator with the joint assembly. The joint assembly comprises a first joint, a second joint and an elastic piece, wherein the first joint comprises a first body with a first water pore and a first guide part with a first accommodating cavity; the second joint comprises a second body with a second water pore and a second guide part with a second accommodating cavity; the shape of the second guide part is adaptive to that of the first guide part, and the second guide part is suitable for being accommodated in the first accommodating cavity; one of the left end and the right end of the elastic piece is connected with one of the first joint and the second joint, and the other one of the left end and the right end of the elastic piece is fixed; and when the second guide part is accommodated in the first accommodating cavity, the elastic piece usually pushes one of the first joint and the second joint to the other one of the first joint and the second joint. The joint assembly for the water pipe of the embodiment of the invention has the advantages of convenience for operation, quick connection and the like.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

Electronic cigarette

The invention discloses an electronic cigarette, which comprises a shell. A heating assembly is arranged in the shell. The electronic cigarette further comprises a fixing mechanism capable of fixing the heating assembly, an unlocking mechanism for controlling the fixing mechanism and the heating assembly to be relatively fixed to each other or separated from each other, and an elastic mechanism for ejecting the heating assembly outwards when the fixing mechanism and the heating assembly are separated from each other. The heating assembly can be popped up to be replaced without making contact with the heating assembly. Therefore, the hands of a user are prevented from being scalded and stained. A top cover assembly can be automatically opened to replace a smoke cartridge only by pressing asliding assembly. The top cover assembly can be reset by pushing the top cover assembly with hands. The situation of inaccurate alignment is avoided. The operation is simple, convenient and fast. Theuser experience is good.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com