Rubber cylinder hydraulic chuck and slip mounting tool and mounting method

An installation tool and rubber cartridge type technology, which is applied in the field of rubber cartridge type hydraulic chuck slip installation tools and installation, can solve the problems of low installation efficiency and high labor intensity, achieve high installation efficiency, high installation accuracy, and ensure correctness neutral effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

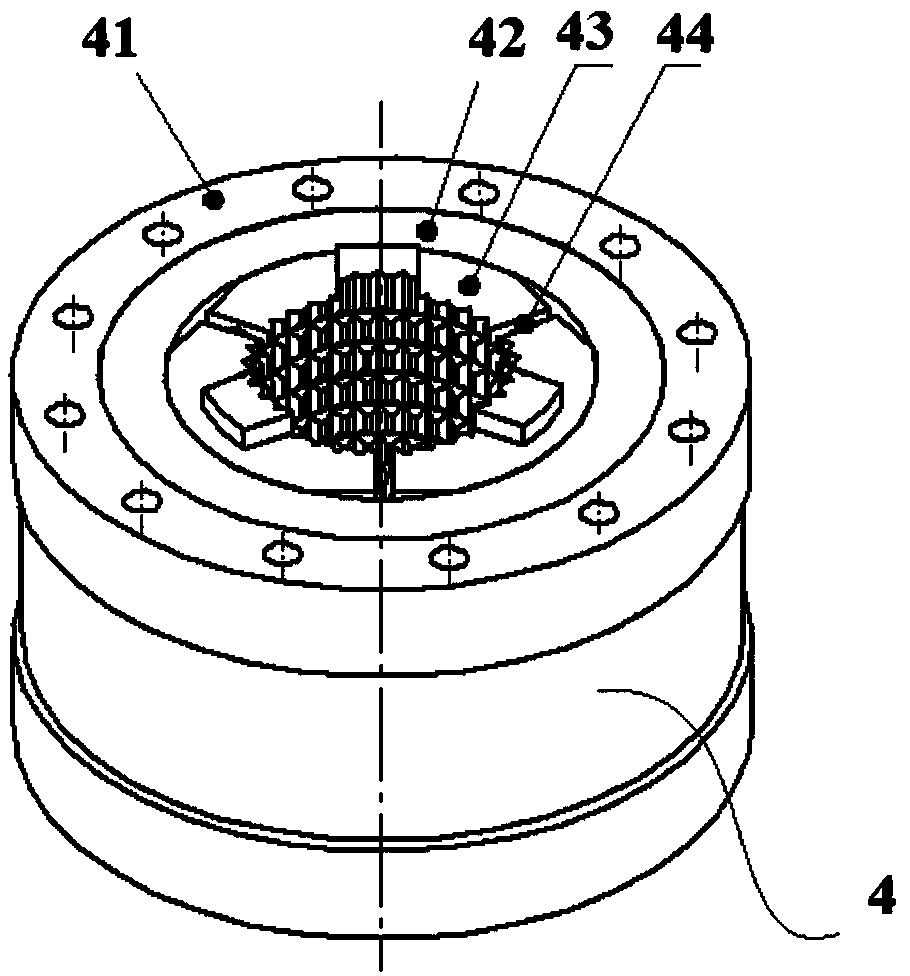

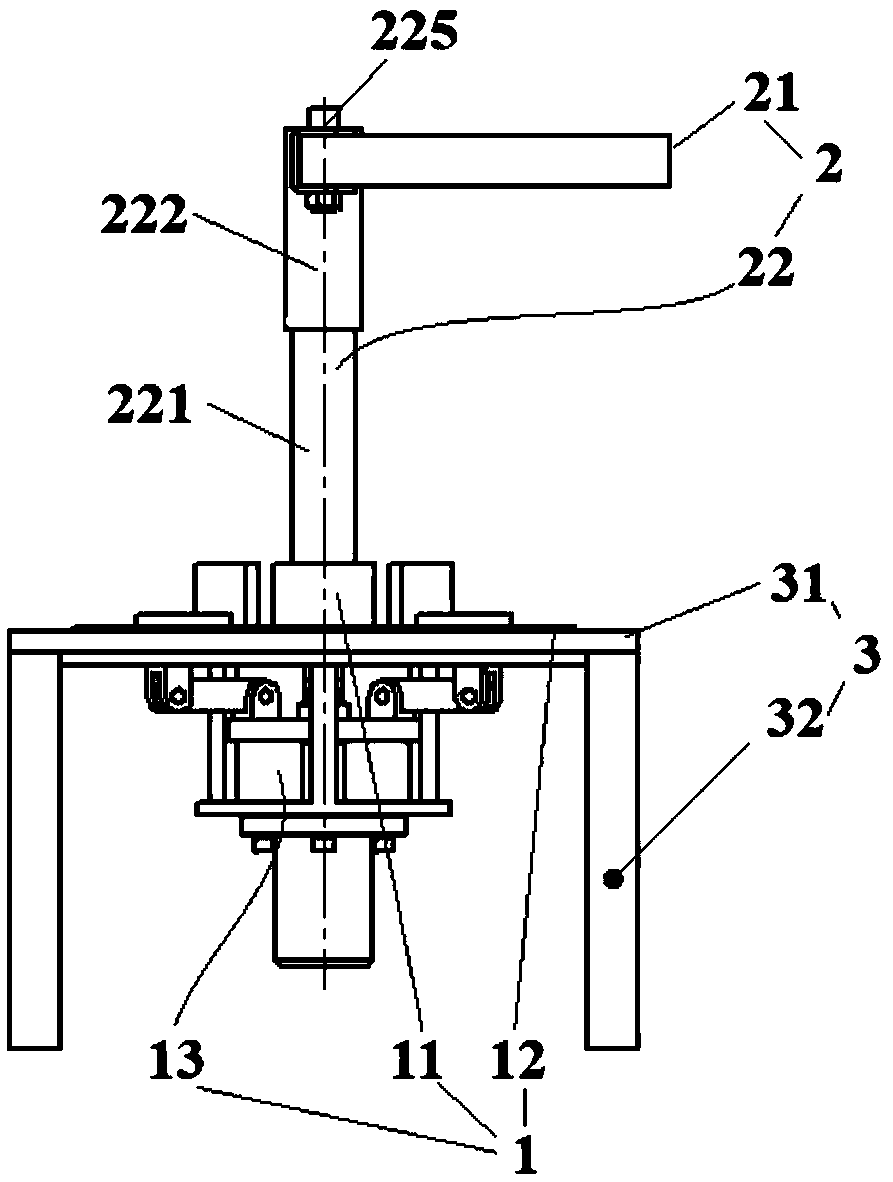

[0056] This embodiment provides a rubber cartridge type hydraulic chuck slip installation tool, such as Figure 3 to Figure 8 As shown, it includes: a support seat 3, the support seat 3 includes a flat plate 31 and a support leg 32; it also includes a tightening mechanism 1 and a pressing mechanism 2, the tightening mechanism 1 is used to tighten the slips along the radial direction of the slips, The pressing mechanism 2 is used to press down the rubber cartridge until it is completely fitted on the outside of the slip; wherein, the tightening mechanism 1 is adjacent to the pressing mechanism 2 and is installed on the supporting base 3 . The rubber cartridge type hydraulic chuck slip installation tool of the present invention is simple in structure, easy to operate, and high in installation efficiency. The tightening mechanism 1 enables the three pieces of slips to overcome the pressure of the return spring and tighten along the radial direction of the slips so that the rubber ...

Embodiment 2

[0071] This embodiment provides a rubber cartridge type hydraulic chuck slip installation method, the installation method is based on the above installation tool, the steps are as follows:

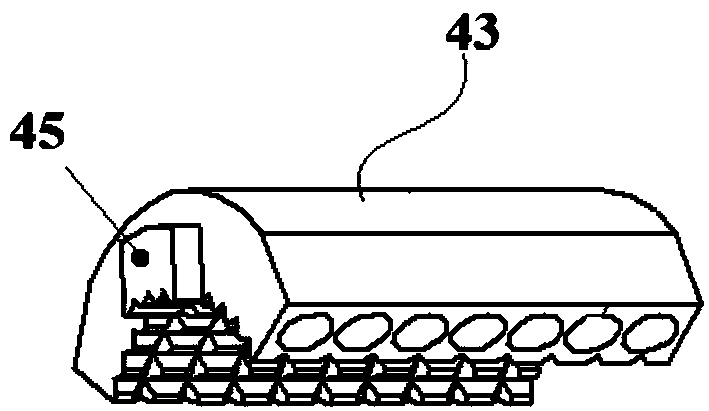

[0072] Step 1: Install slips: such as Figure 9 As shown, the three pieces of slips 43 are respectively placed on the guide plate 12, and the guide block 45 of the slips 43 is embedded in the slide rail 121 of the guide plate 12; hole, and ensure that each return spring 44 is worn in the corresponding cylindrical counterbore of two adjacent slips 43;

[0073] Step 2: Tighten the slips: such as Figure 10 As shown, high-pressure hydraulic oil is introduced into the rod cavity of the tightening cylinder 132, and the piston rod of the tightening cylinder 132 is driven to recover, driving the push-pull plate 131 to move downward, and the push-pull plate 131 drives the three retractable cylinders through three connecting rods 134. The pressing plate 11 moves toward the center of the guide pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com