Method for printing carbon film plate carbon key

A carbon membrane plate and carbon bond technology, which is applied in chemical/electrolytic methods to remove conductive materials and form conductive patterns, can solve problems such as easy errors and affect production quality, improve production quality and efficiency, and optimize processes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

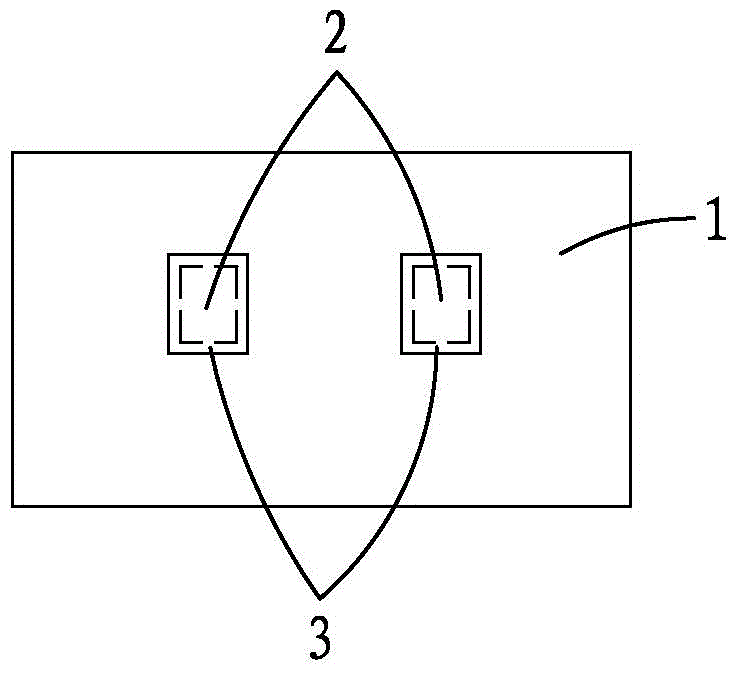

[0018] Such as figure 2 with image 3 As shown, a method of carbon bond printing on a carbon film plate ensures product quality, thereby improving production efficiency.

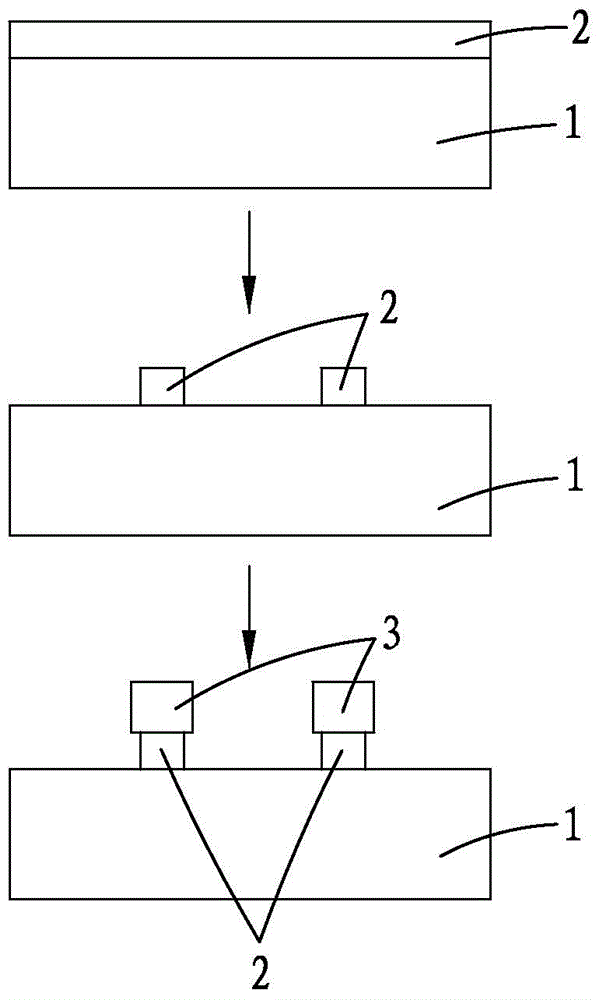

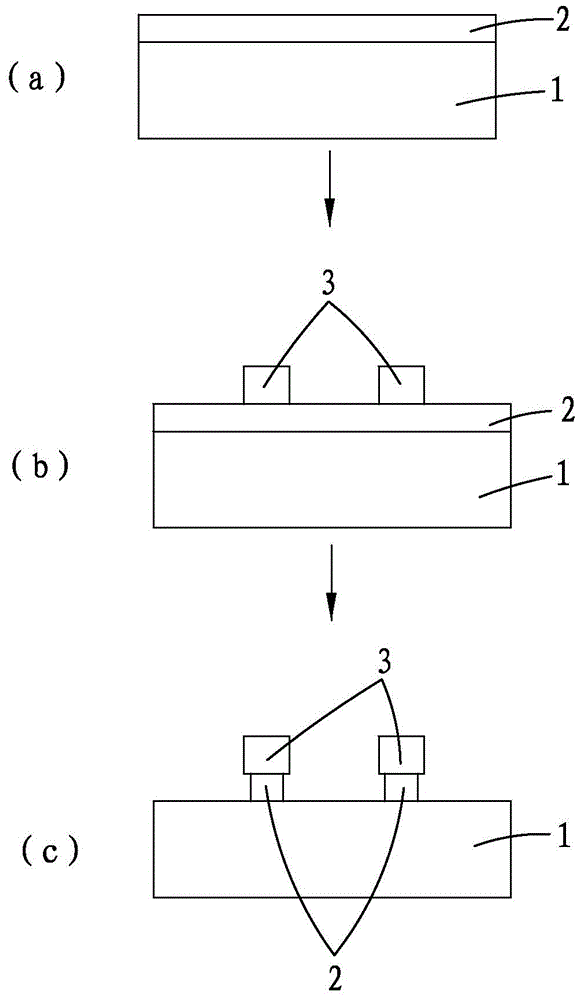

[0019] The present invention is realized as follows: A method for printing carbon bonds on a carbon film plate requires a light plate, such as image 3 As shown in the middle state (a), the light board includes an upper copper layer 2 and a lower substrate 1, and the method includes the following steps:

[0020] Step 10. Print carbon bond 3 on the copper layer 2 of the light board, and cure it. The carbon bond 3 is cured by heat curing, such as image 3 As shown in the middle state (b);

[0021] Step 20: Print the circuit, only perform circuit printing with resist ink on the area without carbon bond, and then perform exposure and development;

[0022] Step 30. Acid etching: etch the metal without carbon bond coverage and the metal without ink protection on the light board to obtain the upper carbon bond and lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com