Split type prefabricated stair integrated forming die and stair production method

A forming mold and split-type technology, which is applied in the direction of molds, manufacturing tools, ceramic molding machines, etc., to achieve the effects of saving mold loading and dismantling processes, improving production efficiency, and saving mold costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054]The following further describes the present invention in combination with specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

[0055]For ease of description, the relative positional relationship of each component, such as the description of top, bottom, left, right, etc., are described in accordance with the layout directions of the accompanying drawings in the specification, and do not limit the structure of the patent.

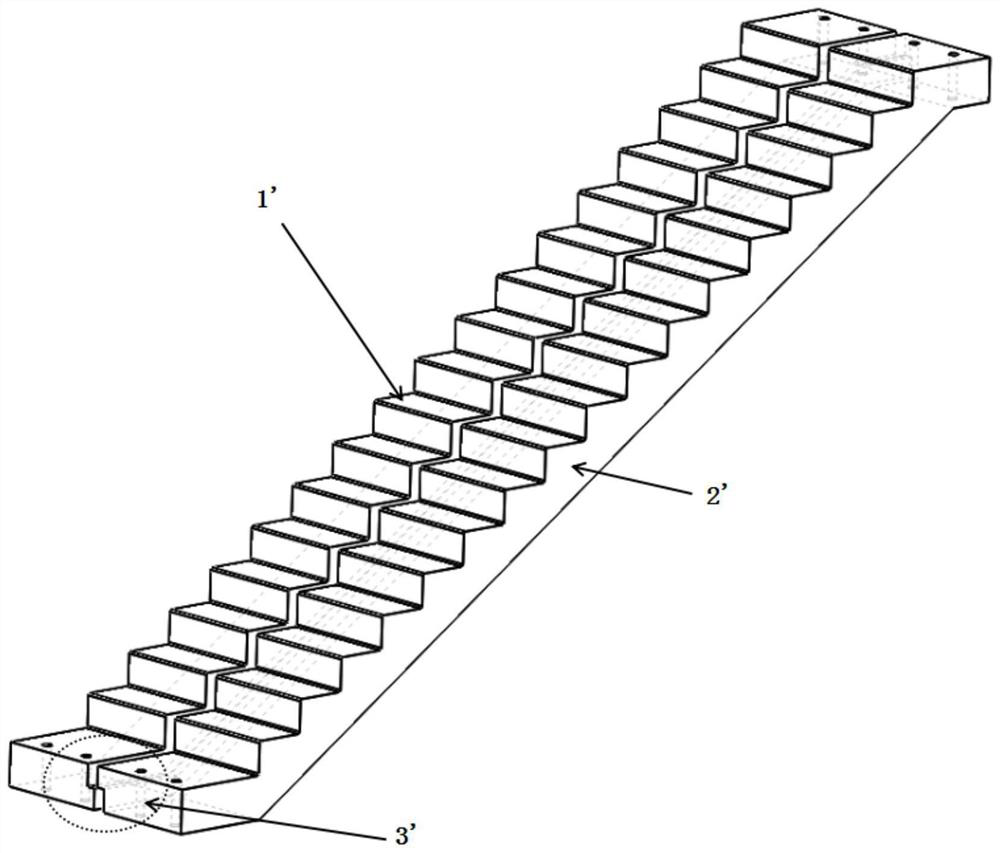

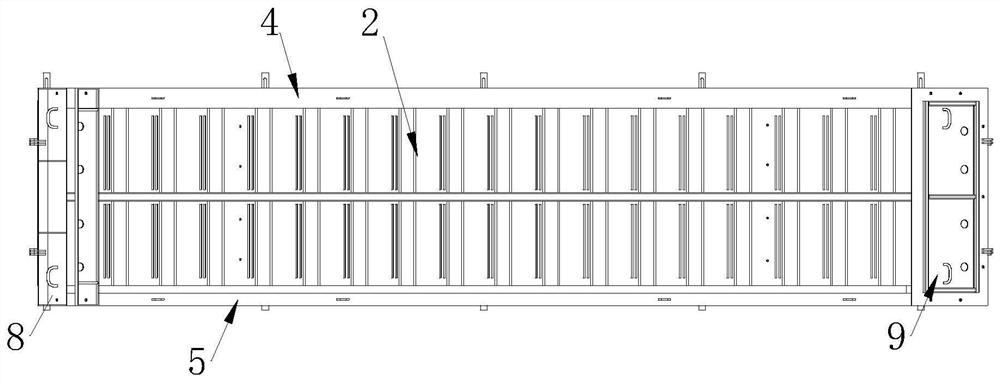

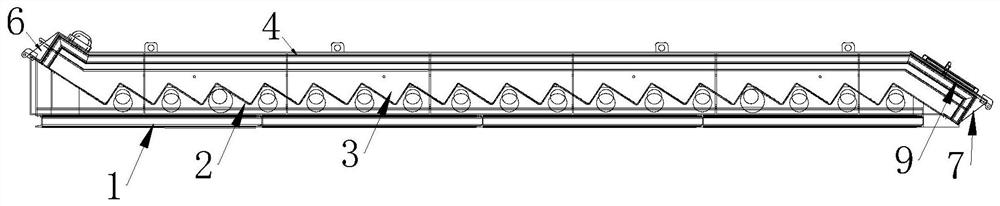

[0056]Such asfigure 1 -Figure 13As shown, an embodiment of the split prefabricated staircase integral molding mold of the present invention includes a base 1, a bottom plate 2, a partition 3, a first side rib 4, a second side rib 5, an upper rib 6, a lower rib 7, Upper cover 8 and lower cover 9.

[0057]The base 1 includes a bottom frame 11 welded by channel steel. The left and right sides of the bottom frame 11 are provided with side rib mounting seats 12, and the side rib mounting seat 12 is provided for instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com