Knitted double-sided machine

A double-sided machine and knitting technology, which is applied in knitting, weft knitting, textiles and papermaking, etc. It can solve the problems of inability to weave knitted fabrics, low running precision, easy misalignment of upper and lower needles, etc., and achieve simple adjustment, high precision, The effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific technical solutions of the present invention will be further described below with reference to the accompanying drawings, so that those skilled in the art can further understand the present invention, without limiting their rights.

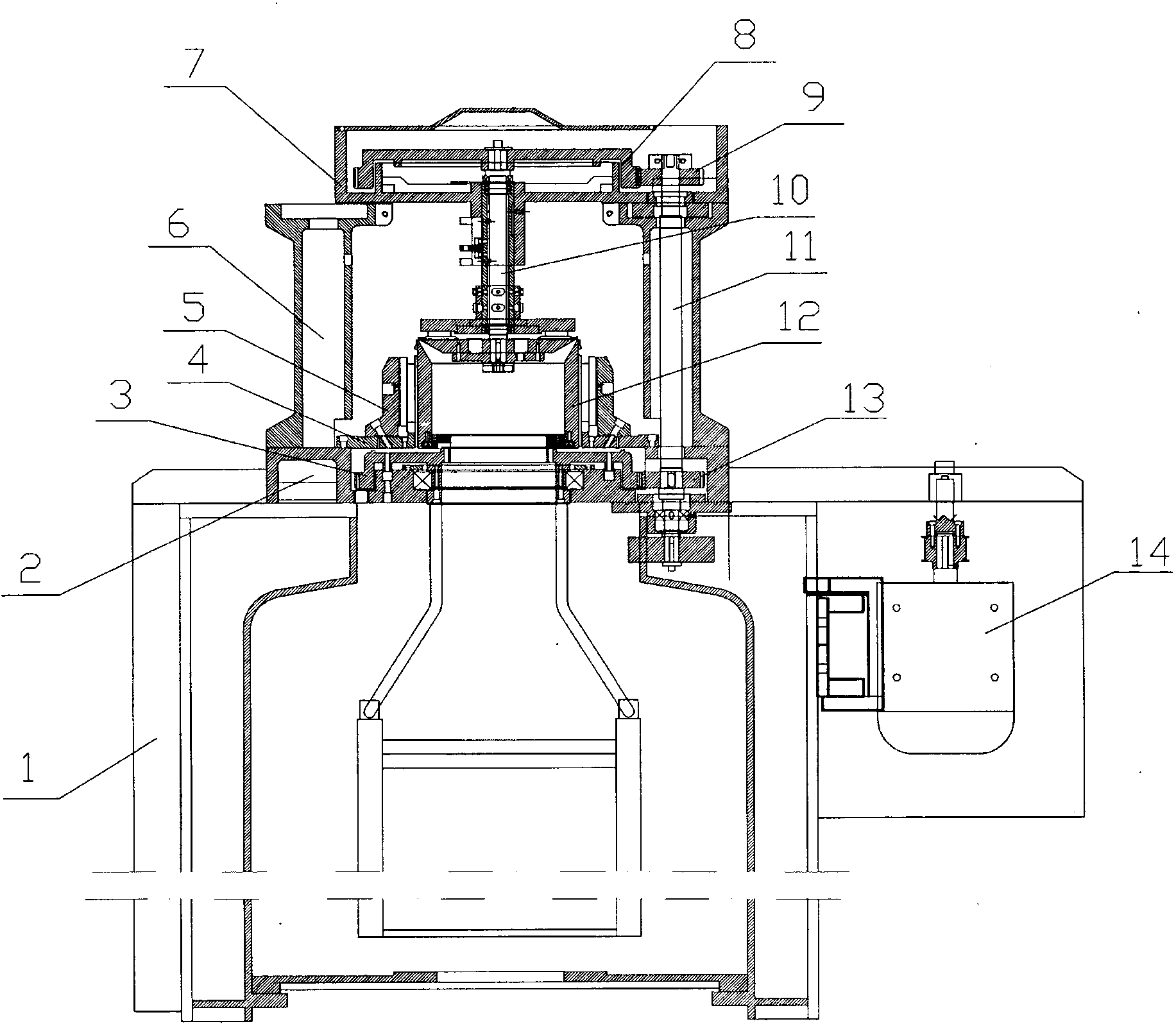

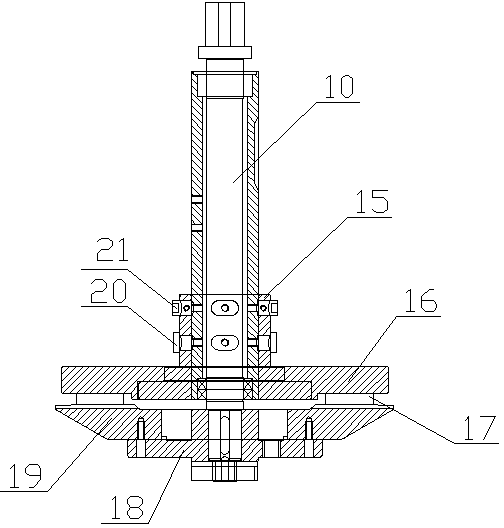

[0011] Refer to attached figure 1 and figure 2 , a double-sided knitting machine, including a bracket 1, a large tripod 7 and a large plate 2, the large plate 2 is fixed on the top of the support 1, and the large tripod 7 is fixed on the large plate 2 through support legs 6. The big tripod 7 is provided with a big tripod gear 8, the middle part of the big tripod gear 8 is coaxially connected with a barrel 10 arranged downward, and the bottom end of the barrel 10 is connected with a dial seat 18 through a key, and is fixed with a round nut. Dial base 18 is connected with dial 19 by screw and jackscrew, can adjust the gap of dial base 18 and dial 19 by screw and jackscrew, makes the gap of dial 19 and dial triangle 17 even, dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com