Bicycle steel pipe welding device

A welding device and bicycle technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve problems such as large cracks and reduced strength of bicycle steel pipes, and achieve the effects of reducing labor intensity, improving work efficiency, and aligning the position accurately.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better understand the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

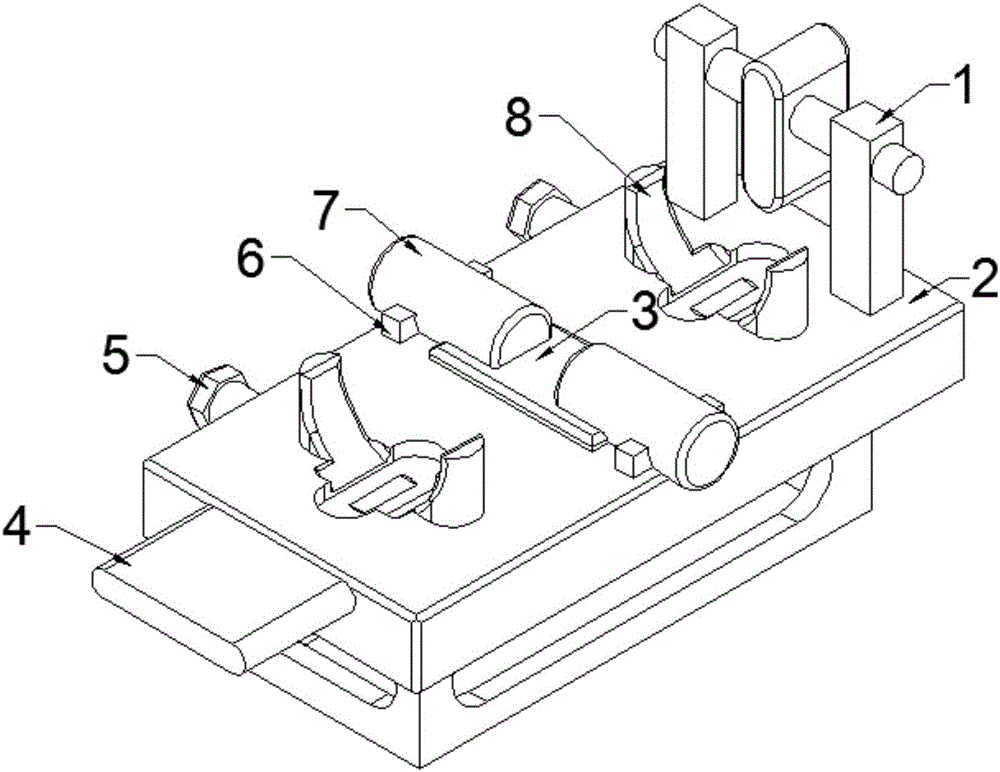

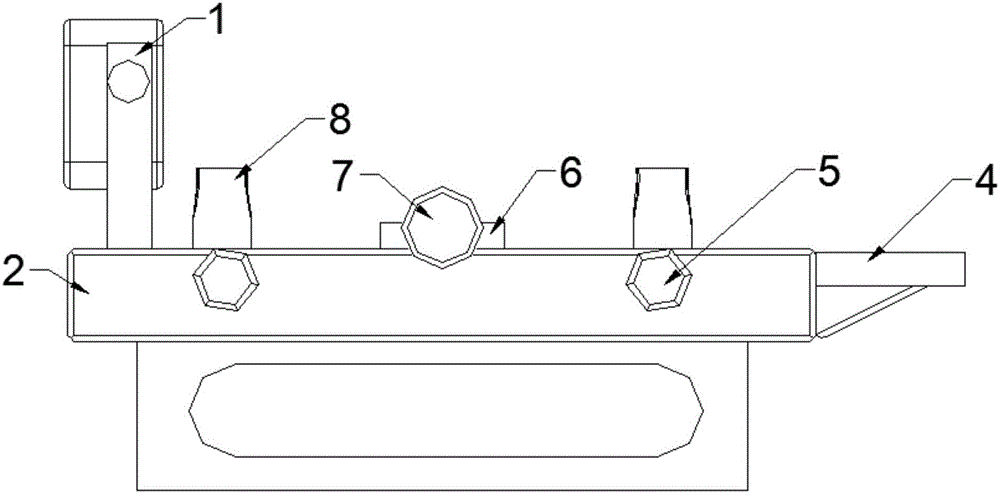

[0022] like Figure 1-2 As shown, a bicycle steel pipe welding device includes a working platform 2, and an adjustable positioning block 8 is arranged on the upper end surface of the working platform 2 with the geometric center line of the working platform 2 as a symmetrical axis. The central position of the working platform 2 is provided with a backing plate 3, and the two sides of the backing plate 3 are provided with a limit rod 7 that can slide on the working platform 2, and the limit rod 7 is provided with a The locking member 6 at the position of the rod 7, the setting direction of the limit rod 7 and the direction of the positioning block 8 are parallel to each other, and a bracket 1 is arranged outside the positioning block 8. On the bracket 1 A top plate for ejecting bicycle steel pipes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com