Paper diaper 3D embossing device

A technology for diapers and embossing, applied in the field of diapers, can solve the problems of waste of resources, failure of normal use of diapers, dislocation of diapers, etc., to achieve the effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

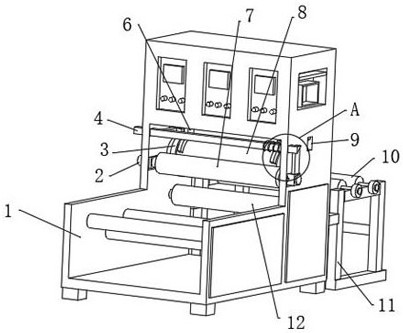

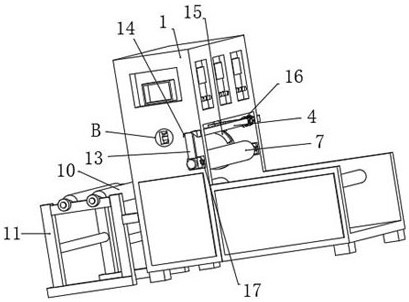

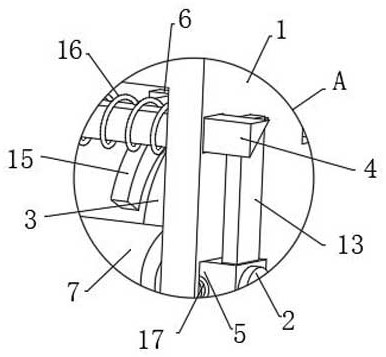

[0027] refer to Figure 1-4 , a 3D embossing device for diapers. The 3D embossing device for diapers includes: a casing 1 and two pressing rollers 7 installed on the casing 1, a second embossing roller 8 is arranged between the two pressing rollers 7, and the casing The first embossing roller 12 used in conjunction with the second embossing roller 8 is installed on the body 1, the housing 1 is used to support the entire diaper 3D embossing device, and a frame 11 is installed on the rear side of the housing 1; two correction rings 3. Two straightening rings 3 are arranged symmetrically at both ends of the second embossing roller 8, and each straightening ring 3 is tightly connected to the housing 1 through the first spring, and the top of the straightening ring 3 is fixedly installed with a cross-section in an L-shape The limit block 21; two trigger mechanisms, the two trigger mechanisms are respectively arranged on the corresponding two limit blocks 21, and the opening 9 for t...

Embodiment 2

[0035] refer to Figure 5-6 , the straightening ring 3 is provided with an arc-shaped chute 18 for connecting the straightening block 15, and the side of the straightening block 15 in contact with the arc-shaped chute 18 is installed with a plurality of bumps 22 with rough surfaces, passing through the straightening ring 3 The arc-shaped chute 18 is set. When the surface layer is about to shift slightly, a plurality of bumps 22 are fixedly connected under the straightening block 15, and the contact surface of the bump 22 and the arc-shaped chute 18 is rough, and the bumps The friction force between 22 and arc-shaped chute 18 is exactly opposite to the direction of surface layer offset, which is beneficial to prevent the surface layer from offsetting, and the moving block 6 has a certain degree of elasticity. When the correction ring 3 is offset, the pendulum The positive block 15 will also move together, and the moving block 6 will undergo a corresponding small deformation. Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com